Rice has been a staple food in many cultures for centuries, with its cultivation dating back thousands of years. Over time, the methods of processing rice have evolved, from hand-pounding in traditional mortars to the rise of modern automatic mills. The advent of these mills has revolutionized the way rice is produced, making it faster, more efficient, and more accessible than ever before. In this article, we will explore the evolution of rice processing and the role that automatic mills have played in shaping the way we enjoy this essential grain.

– From Traditional Methods to Modern Automation: A Brief History of Rice Milling

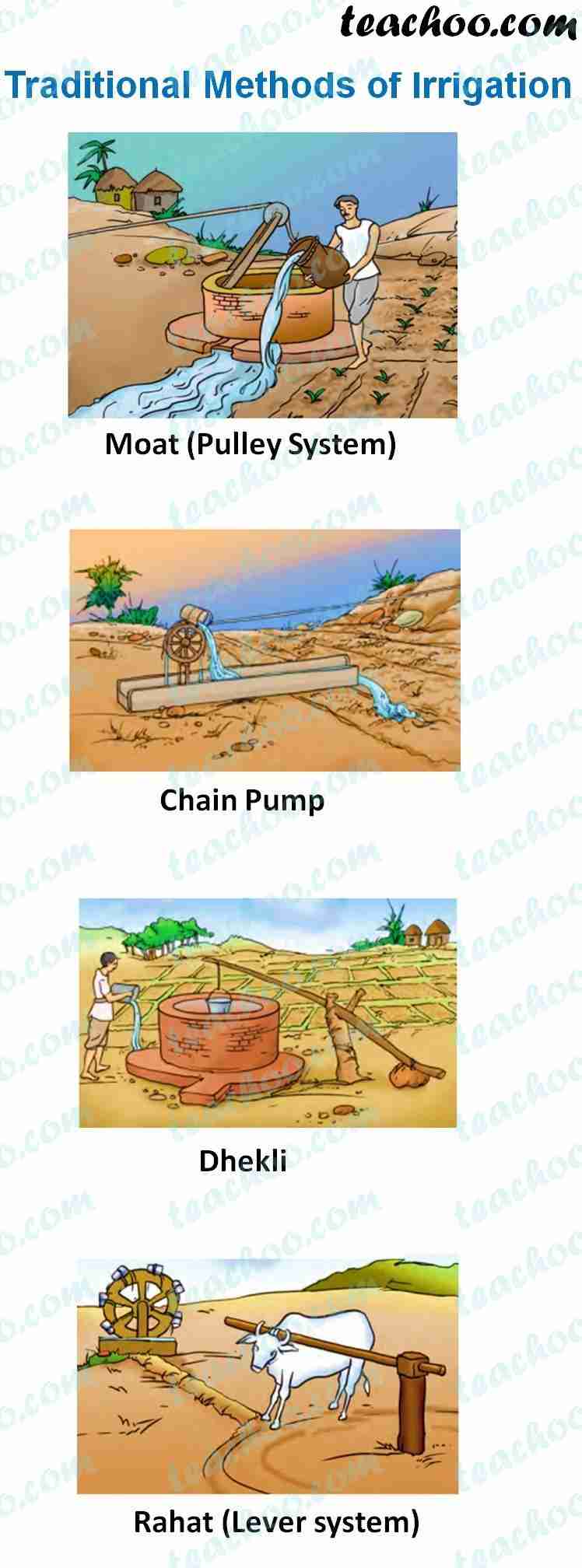

Rice milling has come a long way from its humble origins as a labor-intensive process carried out by hand. Traditional methods involved pounding the rice manually to remove the husk, a back-breaking task that required considerable time and effort. However, with advancements in technology, the rice milling industry saw a transformation with the introduction of modern automation.

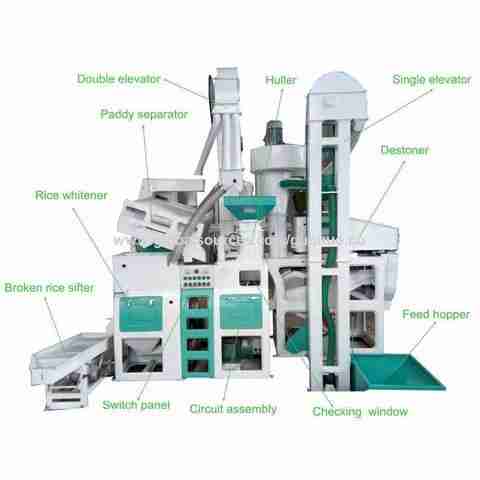

Automatic mills revolutionized the way rice is processed, making the once tedious and time-consuming task a breeze. These state-of-the-art machines are equipped with advanced features that streamline the milling process, from husking and polishing to sorting and packaging. **The evolution of rice milling from traditional methods to modern automation has not only increased efficiency and productivity but has also ensured a higher quality end product for consumers around the world.**

– Efficiency and Precision: The Advantages of Automatic Rice Mills

One of the most significant advancements in the rice industry has been the introduction of automatic rice mills. These mills have revolutionized the way rice is processed, offering a range of benefits that traditional methods simply cannot match. With their cutting-edge technology and precision engineering, automatic rice mills have set a new standard for efficiency and quality in the industry.

One key advantage of automatic rice mills is their ability to process rice quickly and accurately. With automated systems in place, these mills can handle large volumes of rice with ease, ensuring a faster and more streamlined production process. In addition, automatic mills are able to maintain a consistent level of precision in their processing, resulting in higher quality rice products that meet strict industry standards. This level of efficiency and precision not only saves time and labor costs but also ensures that consumers receive the best possible rice products on the market.

- Embracing Innovation: Recommendations for Successfully Transitioning to Automatic Rice Mills

Transitioning to automatic rice mills can be a game-changer for businesses in the rice industry. With advancements in technology, these mills offer increased efficiency, improved productivity, and higher quality output. To successfully make this transition, there are several recommendations to consider:

- Invest in the Right Equipment: Research and invest in modern automatic rice mill machines that best suit your production needs.

- Training and Education: Provide comprehensive training to your staff to ensure they are well-versed in operating and maintaining the new equipment.

- Implement Quality Control Measures: Establish stringent quality control measures to ensure consistent and superior quality rice output.

| Benefit | Advantage |

| Increased Efficiency | Higher productivity and decreased operational costs. |

| Improved Quality | Consistent high-quality rice output for customer satisfaction. |

By embracing innovation and transitioning to automatic rice mills, businesses in the rice industry can stay competitive and meet the growing demands of the market. With the right strategies and implementation of technology, automatic mills can revolutionize the way rice production is done, leading to increased profitability and long-term success.

– Sustainability in Rice Production: How Automatic Mills are Improving Environmental Impact

Rice production has significantly evolved over the years, with automatic mills playing a crucial role in improving the industry’s environmental impact. These innovative mills are revolutionizing the way rice is processed, leading to more sustainable practices and reduced carbon footprint.

By automating the milling process, these mills are able to minimize waste, conserve water, and reduce energy consumption. In addition, the use of advanced technologies in automatic mills results in higher quality rice products, meeting the demands of consumers while prioritizing environmental sustainability. The evolution of rice production through automatic mills is a positive step towards a more eco-friendly and efficient industry.

In Retrospect

As we bid farewell to the journey of rice through the ages, we witness the remarkable transformation brought about by the rise of automatic mills. From humble beginnings to modern marvels of technology, rice has truly come a long way. As we continue to innovate and adapt to the ever-changing world around us, one thing remains constant – the enduring importance of rice in our lives. Let us cherish and appreciate the evolution of this staple food, as we look towards a future where efficiency and sustainability go hand in hand. Here’s to the evolution of rice and the rise of automatic mills, shaping the way we cultivate and consume this vital ingredient for generations to come.