In the world of food production, cereal milling is both a science and an art. From the humble grain to the golden flakes that fill our bowls each morning, the process of turning raw ingredients into breakfast staples is a fascinating journey. Join us as we delve into the intricate world of cereal milling and uncover the secrets behind transforming grain into gold.

The Fascinating History of Cereal Milling Techniques

The process of cereal milling has a long and rich history that dates back thousands of years. Ancient civilizations such as the Egyptians and the Greeks were some of the first to develop techniques for grinding grains into flour. These early milling methods were labor-intensive, with grains being ground by hand using tools such as quern stones.

As technology advanced, so did the art of cereal milling. Water and wind-powered mills were developed in the medieval period, allowing for greater efficiency and increased production. The Industrial Revolution brought even more advancements, with the invention of roller mills that could produce finer, more consistent flour. Today, modern milling techniques combine traditional methods with state-of-the-art technology to produce the high-quality cereals we enjoy today.

Unlocking the Secrets of Perfect Grain Processing

requires a meticulous understanding of every step involved in the cereal milling process. From selecting the finest grains to ensuring precise milling techniques, every detail plays a crucial role in achieving the perfect end product. By mastering the art of cereal milling, one can turn simple grains into golden treasures that delight consumers with their quality and flavor.

One key aspect of achieving perfection in grain processing is the use of advanced milling technologies and equipment. Modern milling machines are equipped with cutting-edge features that enable precise control over factors such as grinding speed, temperature, and particle size distribution. By utilizing these tools effectively, millers can unlock the full potential of grains, resulting in products that boast superior texture, taste, and nutritional value. Additionally, the incorporation of sustainable practices in grain processing not only promotes environmental responsibility but also enhances the overall quality of the final product.

Innovative Technology in Modern Cereal Mills

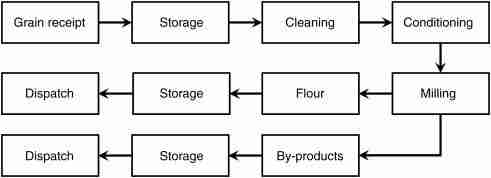

Modern cereal mills have come a long way in terms of incorporating innovative technology to streamline the milling process and enhance the quality of the final product. One of the key advancements in cereal milling technology is the use of precision sorting machines that can quickly identify and separate grains based on color, size, and shape. This ensures that only the highest quality grains are used in the milling process, resulting in a more consistent and superior end product.

Another groundbreaking technology that has revolutionized modern cereal mills is the implementation of automated milling systems. These systems are capable of regulating every aspect of the milling process, from grain intake to packaging, with minimal human intervention. This not only increases efficiency and productivity but also ensures a higher level of food safety and quality control. With the help of these cutting-edge technologies, cereal mills are able to transform grains into gold, providing consumers with nutritious and delicious cereal products that meet the highest industry standards.

Expert Tips for Maximizing Quality and Efficiency

Milling cereal grains is a process that requires precision and expertise to achieve the highest quality and efficiency. One expert tip for maximizing these factors is to carefully select the type of grain to be milled. Different grains have varying characteristics that will affect the final product, so it is important to choose the right grain for the desired outcome.

Another key tip is to properly adjust the milling equipment to ensure optimal performance. This includes setting the correct grind size, moisture levels, and speed to achieve the desired quality and efficiency. Regular maintenance and calibration of the equipment are also essential to prevent issues that can affect the milling process. By following these expert tips, cereal millers can turn grains into gold.

To Conclude

As we come to the end of our exploration into the art of cereal milling, we have delved into the intricate process of transforming grains into the golden flakes and crunchy puffs that fill our breakfast bowls. From the ancient techniques of stone milling to the modern innovations in industrial processing, cereal milling continues to be a fascinating blend of tradition and technology. As we savor each spoonful of our favorite cereals, let us remember the skilled artisans and engineers who bring us this beloved breakfast staple. And next time you pour yourself a bowl, take a moment to appreciate the journey from grain to gold that brings us the delicious crunch we all know and love.