In the heart of bustling villages and tranquil countryside, a quiet artistry unfolds amidst the rustle of dry corn stalks – the art of maize milling. From the humble seed to the fine powder that fuels our daily bread, maize milling is a time-honored craft that transcends generations. Join us as we embark on a journey through the intricate process of transforming maize kernels into the golden flour that sustains millions around the world. Welcome to the enchanting world of maize milling – where simplicity meets sophistication, and tradition meets innovation.

The Origins and Evolution of Maize Milling Techniques

Maize milling has been a crucial part of human history, dating back thousands of years. Early civilizations such as the Mayans and Aztecs utilized primitive grinding methods to process maize kernels into flour. Over time, technological advancements have revolutionized the milling process, leading to more efficient and refined techniques.

One of the key innovations in maize milling was the development of stone mills, which allowed for a finer grind of the maize kernels. As milling techniques continued to evolve, the introduction of roller mills in the 19th century further improved the efficiency and quality of maize flour production. Today, modern maize milling facilities utilize state-of-the-art equipment to produce a wide range of maize products, catering to diverse consumer needs and preferences.

Navigating the Maize Milling Process: Equipment and Best Practices

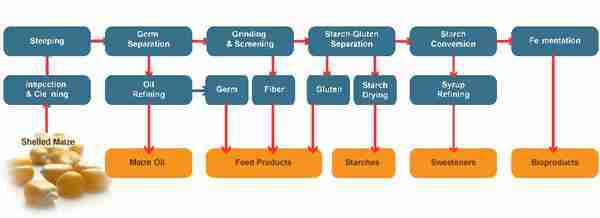

In the maize milling process, having the right equipment is crucial for ensuring a high-quality end product. One key piece of equipment is the hammer mill, which is used to break down the maize into smaller particles. Another essential component is the roller mill, which further refines the maize into flour. To ensure efficiency and consistency, it’s important to invest in high-quality equipment that is properly maintained.

In addition to having the right equipment, following best practices is essential for successful maize milling. One important practice is to properly clean and sanitize the equipment between batches to prevent contamination. It’s also important to adjust the settings on the milling equipment based on the desired final product. By following these best practices, you can ensure that your maize milling process runs smoothly and produces high-quality flour.

Key Considerations for Producing High-Quality Maize Flour

Producing high-quality maize flour is a delicate process that requires attention to detail every step of the way. From selecting the right maize seeds to ensuring proper storage conditions, each decision can have a significant impact on the final product. One key consideration is the quality of the maize seeds themselves. Starting with premium, non-GMO maize seeds is essential for producing flour that is both nutritious and flavorful.

Another important factor to consider is the milling process. Using the right equipment can make a big difference in the quality of the flour produced. Investing in a high-quality maize mill that is properly calibrated and maintained is crucial for achieving consistent results. Additionally, paying attention to factors such as moisture content, temperature, and milling speed can help ensure that the maize is ground to the perfect texture for the desired end product.

Innovations in Maize Milling Technology: Enhancing Efficiency and Product Quality

When it comes to maize milling, the focus is on maximizing efficiency and maintaining top-notch product quality. With the continuous advancements in technology, the milling process has evolved to become more streamlined and effective than ever before. One of the key innovations in maize milling technology is the incorporation of state-of-the-art equipment that allows for faster and more precise processing of maize kernels. This has led to increased productivity and reduced wastage, ultimately resulting in higher yields of quality maize flour.

Moreover, the adoption of automated systems in maize milling plants has revolutionized the industry by significantly reducing human error and increasing overall output. These systems are equipped with sensors and monitors that constantly analyze and adjust the milling process to ensure consistency and uniformity in the final product. Additionally, the implementation of quality control measures at every stage of the milling process guarantees that only the best maize flour makes its way to the market, satisfying the demands of consumers and enhancing the reputation of the milling industry as a whole.

The Way Forward

As we have explored the intricate process of maize milling from seed to flour, it is evident that this age-old practice is truly an art form that requires precision, patience, and skill. From the cultivation of the maize plant to the grinding of the kernels into fine flour, each step plays a crucial role in producing the end product that we all know and love. So the next time you enjoy a delicious meal made with maize flour, take a moment to appreciate the craftsmanship that goes into this humble ingredient. The art of maize milling is not just a job, but a labor of love that connects us to the land, our ancestors, and to each other.