Rice, a staple in many cultures around the world, has been a key ingredient in countless dishes for centuries. As technology continues to advance, the way rice is milled is undergoing a revolution. Automatic plant efficiency is taking center stage, streamlining the process and maximizing productivity. Join us as we delve into how this innovation is transforming the rice milling industry and what the future holds for this vital aspect of global food production.

Introduction to Automatic Rice Milling Technology

Automated rice milling technology has transformed the way rice is processed, bringing efficiency and accuracy to the forefront of the industry. With the advancement of automatic plant systems, rice milling has become faster, more precise, and less labor-intensive. This revolutionary technology has allowed rice millers to increase their production capacity while maintaining high-quality standards.

- Reduce processing time

- Improve milling precision

- Decrease labor costs

By exploring the benefits of automatic rice milling technology, mill owners can streamline their operations, increase overall productivity, and meet the growing demand for rice products in the market. With the integration of automation into the rice milling process, plant efficiency is significantly enhanced, providing a competitive edge in the industry.

Maximizing Efficiency with Automated Plant Operations

Rice milling has seen a significant shift towards automation in recent years, with plant operations becoming more efficient and streamlined than ever before. These automated systems allow for precision in every step of the process, from cleaning and dehusking to polishing and packaging. By eliminating manual labor and human error, plants can achieve higher output levels and consistent quality in their products.

With the implementation of automated plant operations, rice milling companies can maximize efficiency and reduce operational costs. By utilizing cutting-edge technology such as sensors, robotics, and AI algorithms, plants can optimize production schedules, minimize wastage, and improve overall productivity. The future of rice milling lies in automation, revolutionizing the industry and setting new standards for efficiency and quality.

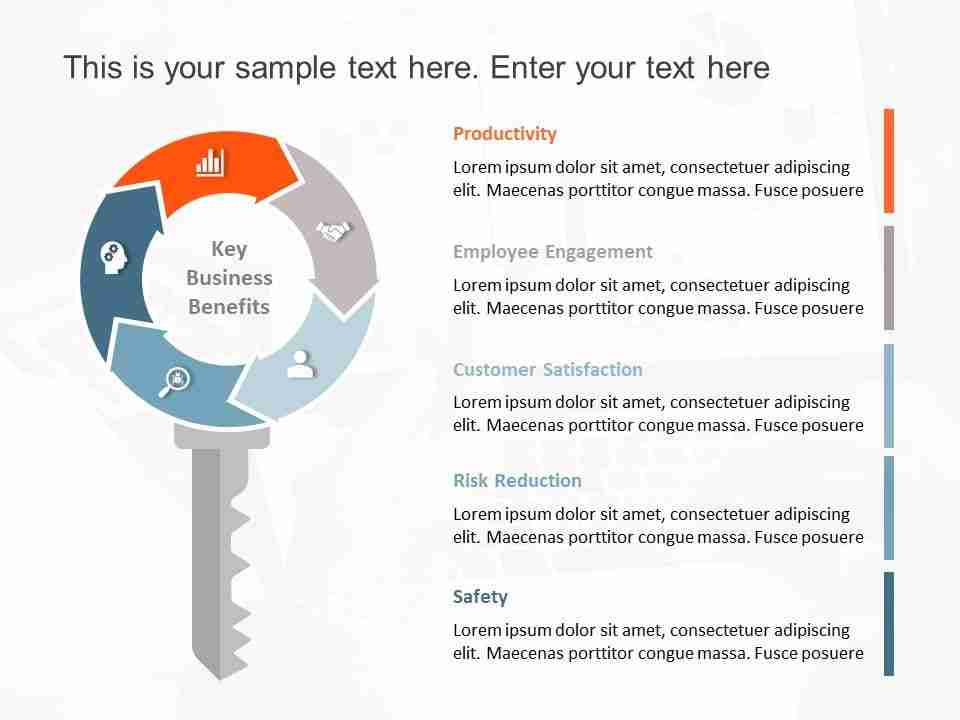

Key Benefits of Implementing Automatic Rice Milling Systems

Automatic rice milling systems have revolutionized the rice industry, offering a plethora of benefits that traditional methods simply cannot match. One key advantage is the significant increase in efficiency these systems provide. With advanced technology and automation, the entire milling process is streamlined, resulting in higher output and reduced labor costs.

Moreover, automatic rice milling systems ensure consistency in the quality of the final product. By utilizing precision machinery and computer-controlled processes, these systems can guarantee uniformity in rice milling, grading, and packaging. This not only enhances the marketability of the rice but also increases customer satisfaction and trust in the brand. Additionally, these systems are designed for easy maintenance and operation, making them user-friendly and cost-effective in the long run.

Improving Quality Control and Consistency in Rice Production

Rice production has long been a staple in agriculture, but ensuring quality control and consistency has always been a challenge. With the latest advancements in technology, automatic plant efficiency is revolutionizing rice milling processes. By implementing state-of-the-art equipment and software, rice producers can now streamline their operations to achieve higher standards of quality and consistency.

With automatic plant efficiency, rice producers can optimize their production processes, leading to improved quality control and consistency in every batch of rice. By utilizing advanced sensors, data analytics, and automation systems, producers can monitor and adjust key parameters in real-time to ensure that each grain meets the desired specifications. This level of precision and accuracy not only improves the overall quality of the product but also boosts efficiency and reduces waste. Embracing this technology is essential for modern rice mills looking to stay competitive in today’s market.

The Way Forward

As we continue to delve into the advancements in rice milling technology, it is clear that automatic plant efficiency is revolutionizing the industry. With the ability to streamline processes and increase productivity, these innovative solutions are paving the way for a more sustainable and profitable future for rice producers worldwide. By embracing automation and harnessing the power of cutting-edge technology, we are ushering in a new era of efficiency and innovation in rice milling. Join us as we explore the endless possibilities that automatic plant efficiency has to offer, and witness the transformative impact it is having on the industry. Revolutionize your rice milling operations today and experience the benefits of a more efficient and profitable future.