Nestled in the heart of lush green paddies, a hidden gem lies quietly churning out one of the world’s most essential staples – rice. Step inside the intricate world of a paddy processing unit and witness the rice revolution unfold before your eyes. Join us on a journey through the intricate processes and meticulous attention to detail that go into transforming humble grains of rice into the culinary staple that feeds millions around the globe.

Unveiling the Inner Workings of a Paddy Processing Unit

In the heart of every rice-producing region lies a paddy processing unit, where the magic of turning raw paddy into edible rice takes place. As you step inside one of these units, the symphony of machines whirring and workers bustling about creates an atmosphere of controlled chaos.

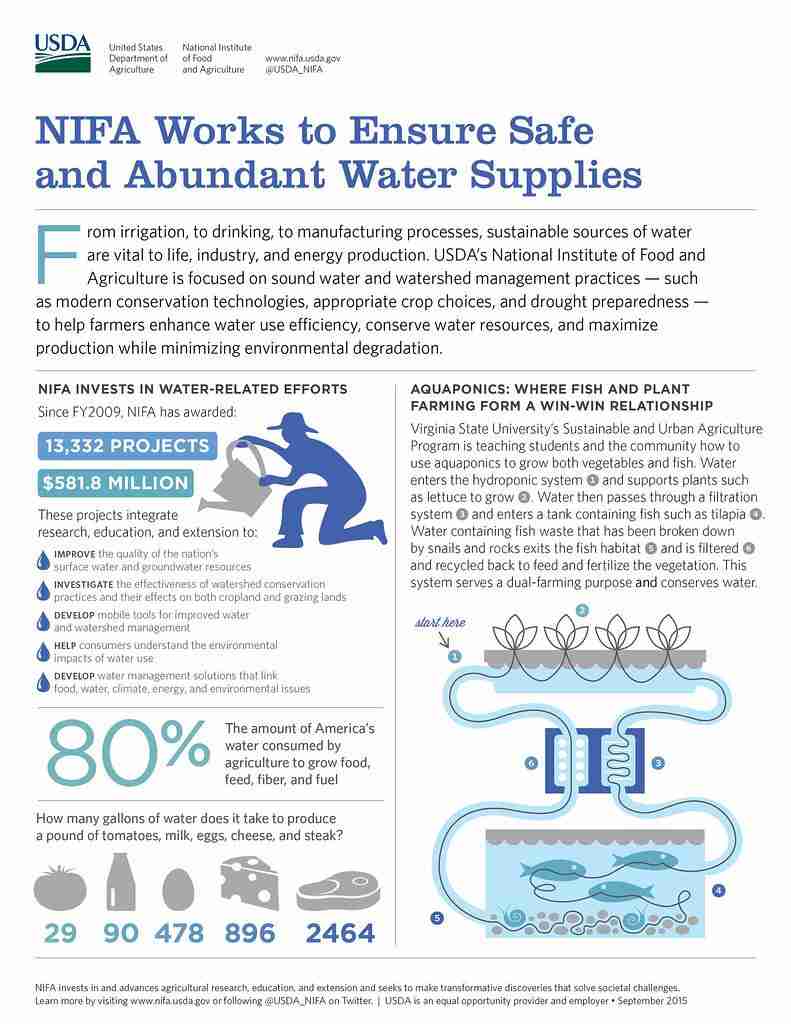

From the moment the raw paddy enters the unit to the final packaging of the rice, each step in the process is crucial to ensure the quality and consistency of the end product. Let’s delve into the inner workings of a paddy processing unit and uncover the fascinating journey of rice from field to plate:

Maximizing Efficiency Through Modern Technology and Automation

At the heart of the rice revolution lies the innovative technology and automation employed in paddy processing units. These state-of-the-art facilities utilize cutting-edge machinery to streamline the process of turning raw paddy into the polished rice we all know and love. Through the integration of modern technology, these units are able to maximize efficiency and output while maintaining the quality of the final product.

One of the key components of these paddy processing units is the use of automated sorting and grading systems. These systems can quickly and accurately sort out impurities, broken grains, and other unwanted materials, ensuring that only the highest quality rice makes it to the final packaging. Additionally, automated packaging and labeling machines help to speed up the final stages of production, allowing for a faster turnaround time from paddy to packaged rice. Overall, the combination of modern technology and automation in these units is revolutionizing the rice industry and paving the way for increased efficiency and productivity.

Ensuring Top Quality Rice: From Milling to Packaging

At our paddy processing unit, we take great care in ensuring top quality rice for our customers. From the moment the raw paddy grains are received to the final packaging stage, every step of the process is meticulously monitored to maintain the highest standards of quality.

- Milling: Our state-of-the-art milling machines are equipped with the latest technology to efficiently remove husk, bran, and other impurities from the grains, resulting in clean and polished rice kernels.

- Sorting: After milling, the rice undergoes thorough sorting to remove any remaining impurities and broken grains, ensuring that only the best quality grains make it to the next stage of processing.

| Type | Quality |

|---|---|

| Basmati Rice | Premium |

| Jasmine Rice | Grade A |

| Long Grain Rice | Standard |

Our commitment to quality extends to the packaging stage, where each bag of rice is carefully sealed to preserve freshness and prevent any contamination. We take pride in delivering top quality rice products that meet the expectations of our valued customers.

Sustainable Practices for a Greener Paddy Processing Unit

In our quest for a more sustainable future, we delved deep into the operations of a cutting-edge paddy processing unit to uncover the practices that are revolutionizing the rice industry. One standout feature is the utilization of renewable energy sources such as solar panels and biogas digesters, significantly reducing the unit’s carbon footprint.

Furthermore, the unit boasts state-of-the-art water recycling systems that minimize water wastage during the processing of rice. By reusing water for multiple cycles, this innovative approach not only conserves water but also reduces operating costs. The commitment to sustainable practices extends beyond production, with the unit also implementing organic waste composting to reduce landfill waste and promote soil health.

Key Takeaways

In conclusion, the rice revolution is vital for our sustenance and economic growth. The intricate process of paddy processing in a modern unit showcases the careful craftsmanship and innovation behind our humble bowl of rice. By understanding and appreciating the efforts put into each grain, we can truly grasp the significance of rice in our daily lives. Next time you enjoy a plate of steaming hot rice, remember the journey it took from the paddy fields to your table. Let’s raise a toast to the unsung heroes working tirelessly in paddy processing units, ensuring that we never run out of our favorite staple. Let the rice revolution continue to thrive and nourish us for generations to come.