The Art and Science of Cereal Milling: From Grain to Grain

In the quiet hum of a mill, where the rhythmic grind of machinery meets the earthy aroma of freshly milled grain, lies a process that is both an ancient craft and a modern marvel. Cereal milling, often overshadowed by the final product that fills our breakfast bowls, is a complex interplay of art and science. It transforms humble grains into a versatile array of flour, with each stage meticulously crafted to unlock the potential held within the seed. This article invites you on a journey through the intricate stages of cereal milling, exploring the techniques honed over centuries, the cutting-edge innovations shaping the industry today, and the fascinating balance that ensures the quality and consistency of our staple foods. From the field to the mill and ultimately to our tables, discover how the delicate dance between tradition and technology culminates in the grains that nourish our lives.

Understanding the Grain: Exploring Varietals and Their Impact on Flour Quality

Grains are far more than mere ingredients; they are the very foundation of flour quality, with each varietal contributing unique characteristics. The type of grain used in milling influences everything from flavor to texture, ultimately shaping the culinary experience. Key varietals like hard red wheat, soft white wheat, and durum wheat exhibit distinct gluten structures and protein contents, which play pivotal roles in determining how the flour will behave in various recipes. Understanding these differences can be essential for bakers, allowing them to select the right flour that will enhance their creations and achieve desirable results.

In addition to wheat, other grains, including rye, barley, and oats, offer further diversity in flour quality. Each of these grains comes with its own set of flavors and functionalities, often imparting health benefits as well. For instance, rye flour can add a robust earthy flavor and a moist crumb to bread, while oat flour lends a creamy texture and subtle sweetness. Exploring the varying protein levels and gluten strengths among these grains can lead to an intrinsic understanding of how to mix and match them for optimal baking results. The table below illustrates some of the key properties of different grain varietals:

| Grain Type | Protein Content | Gluten Strength | Flour Use |

|---|---|---|---|

| Hard Red Wheat | 12-15% | Strong | Breads, Pastas |

| Soft White Wheat | 9-11% | Weak | Cakes, Pastries |

| Durum Wheat | 13-15% | Very Strong | Pasta |

| Rye | 10-15% | Moderate | Breads, Crackers |

| Oats | 10-14% | None | Health Foods, Baked Goods |

The Milling Process: Balancing Tradition and Technology for Optimal Results

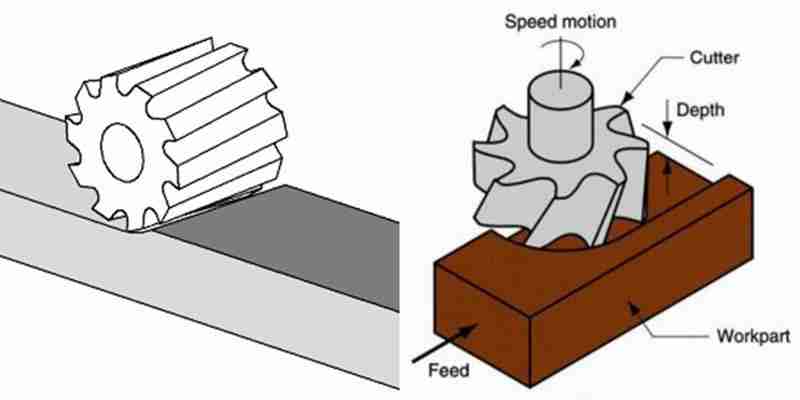

The milling process is a fascinating interplay between age-old techniques and contemporary innovations, ensuring that the best of both worlds is harnessed to deliver superior quality flour. Traditional milling methods, such as stone grinding, emphasize preserving the nutritional value and unique flavors inherent in grains. Modern milling, on the other hand, employs advanced machinery and precision technology to enhance efficiency, consistency, and scalability. This blending of techniques allows millers to produce flour with optimal characteristics tailored to diverse culinary applications.

In achieving the perfect flour, millers must consider various factors, including grain selection, moisture content, and milling techniques. The following aspects are paramount to this balancing act:

- Grain Quality: Choosing the right grain variety impacts the final product’s taste and texture.

- Process Control: Monitoring parameters like temperature and speed during milling can prevent quality degradation.

- Technological Integration: Implementing automation and real-time data analytics allows for precise adjustments in the milling process.

| Aspect | Traditional Method | Modern Method |

|---|---|---|

| Equipment | Stone mill | Roller mill |

| Efficiency | Low | High |

| Nutritional Retention | High | Moderate |

Quality Control in Milling: Ensuring Consistency and Safety from Farm to Table

Ensuring quality in the milling process is a meticulous journey that begins at the very source — the grain. Every batch of cereal grains, whether it’s wheat, corn, or oats, is subjected to rigorous quality assessments before it even enters the mill. This includes evaluating factors such as moisture content, protein levels, and grain hardness. By employing advanced technologies, millers can achieve consistent flour and meal quality that meets both consumer needs and safety standards. Key quality control processes involve:

- Visual Inspection: Checking for foreign materials and overall grain integrity.

- Laboratory Analysis: Testing for biochemical properties and contamination levels.

- Moisture Regulation: Adjusting grain moisture to optimal levels for milling efficiency.

Following processing, the product undergoes further quality assurance measures to maintain the highest safety standards. Sampling and testing are performed at various stages, ensuring that each product leaving the facility meets regulatory guidelines and customer expectations. Some essential finishing steps in quality control include:

- Batch Testing: Analyzing end products for texture, flavor, and nutritional value.

- Cross-Contamination Checks: Implementing strict cleaning protocols to avoid allergenic ingredients.

- Traceability Systems: Keeping records from farm to table, ensuring accountability and safety.

Sustainability in Cereal Milling: Innovations for a Greener Future

The cereal milling industry stands at the forefront of incorporating sustainable practices, marrying innovation with environmental stewardship. Advances in technology are transforming the traditional milling process, minimizing waste and boosting efficiency. For instance, renewable energy systems such as solar panels and wind turbines are increasingly integrated into milling facilities, drastically reducing their carbon footprint. Moreover, smarter machinery equipped with AI-driven sensors optimizes energy consumption and ensures that every grain is utilized effectively, resulting in minimal by-product waste.

Additionally, the use of by-products is gaining traction as innovators devise methods to repurpose materials that might otherwise end up in landfills. By creating circular economy models, companies can transform bran and germ into high-value products such as animal feed or nutritional supplements. The following table showcases some innovative approaches in sustainable cereal milling:

| Innovation | Description |

|---|---|

| Biomass Fuel | Using husks and chaff as sustainable fuel sources for energy. |

| Water Recycling | Implementing systems that treat and reuse water in the milling process. |

| Smart Sensors | AI technology that monitors and optimizes resource use. |

Concluding Remarks

As we draw the curtain on our exploration of “The Art and Science of Cereal Milling: From Grain to Grain,” we hope you’ve gained a deeper appreciation for the intricate processes that transform humble grains into staple foods that grace our tables. It is a journey that marries craftsmanship with precision, where ancient techniques meet modern technology to create the flour that fuels our culinary ambitions.

From the carefully selected grains to the methods employed in milling, each step is a testament to the dedication of millers who masterfully balance tradition and innovation. As we reflect on the intricate relationship between the field and the finished product, it becomes clear that cereal milling is not merely a mechanical process but an alchemical art, one that nourishes both body and spirit.

Next time you pour a bowl of your favorite cereal or knead dough for homemade bread, consider the remarkable journey those grains undertook, culminating in the textures and flavors you enjoy. As we continue to uncover the stories behind our food, may we remember the craftsmanship that ensures every bite is not just a meal, but a connection to the cycles of nature and the community of those who cultivate it. Thank you for joining us on this enlightening journey—may it inspire a newfound appreciation for the grains that nourish us all.