Turning Rice: Inside the Journey of a Paddy Processing Plant

In the heart of agricultural landscapes, where golden fields sway gently in the breeze, an age-old story unfolds—the transformation of humble paddy into the staple that graces tables around the world. Welcome to the world of rice processing, a journey that begins with the sowing of seeds and winds through intricate machinery to deliver the perfect grain. In this article, we take you behind the scenes of a paddy processing plant, exploring the delicate interplay of tradition and technology that defines this vital industry. From the rhythmic hum of machinery to the meticulous quality checks, we will uncover the processes that not only preserve the essence of rice but also amplify its potential. Join us as we delve into this fascinating world and discover the unseen effort that turns the farmer’s bounty into a pantry staple enjoyed by millions.

Exploring the Mechanics of Paddy Processing

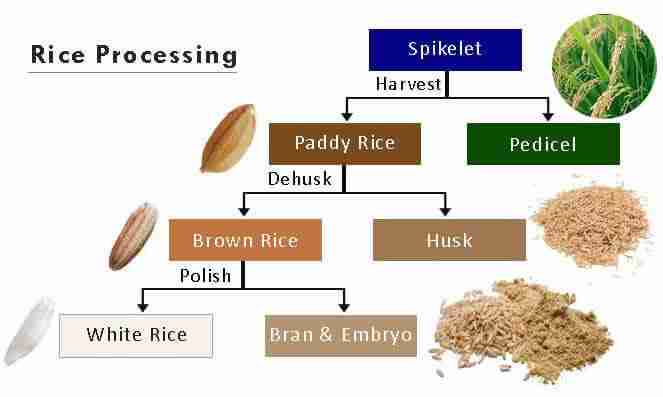

The paddy processing journey begins right after harvesting, where freshly cut rice plants are transported to the processing plant. Upon arrival, the first task is to thresh the rice, a mechanical action that separates the grains from the stalks. Following this, the grain undergoes a meticulous drying process, crucial for preserving its quality. Failure to dry properly can lead to mold and spoilage. Moreover, paddy processing plants employ various technologically advanced methods, including de-stoning, which removes foreign materials, and parboiling, which enhances the nutritional quality of the rice. Each step is vital, ensuring that only the best quality rice reaches consumers.

Once the grain is adequately prepared, it moves to the milling stage, where the outer layers of bran are removed to reveal the white rice inside. This stage includes whitening and polishing processes, enhancing appearance and taste. The final output is categorized based on various grades, which influences market value and consumer preference. Below is a simplified representation of the milling process to visualize the key stages:

| Stage | Description |

|---|---|

| Harvesting | Collection of mature rice plants |

| Threshing | Separation of grains from stalks |

| Drying | Reducing moisture content for preservation |

| De-stoning | Removal of foreign materials |

| Milling | Removing bran layers to produce white rice |

The Role of Technology in Enhancing Rice Production

In the ever-evolving world of agriculture, cutting-edge technology plays a pivotal role in reshaping traditional practices and enhancing efficiencies in rice production. By integrating advanced equipment and innovative methodologies, farmers can significantly boost yield and improve the quality of rice harvested. Technologies such as precision agriculture tools allow for data-driven decision making, leading to optimized resource utilization. Key benefits include:

- Soil health monitoring: Smart sensors analyze soil conditions, ensuring optimal nutrient levels.

- Irrigation management: Automated systems adjust water supply based on real-time weather data.

- Drone technology: High-resolution aerial imagery facilitates better field management and pest control.

Furthermore, data analytics and artificial intelligence empower farmers by predicting harvest times and potential challenges in the field. This predictive capability minimizes risks and maximizes productivity. The integration of smart machinery, such as automated harvesters and compact rice milling units, not only reduces labor costs but also ensures that rice processing is completed swiftly and efficiently. A snapshot of how technology impacts rice production can be illustrated in the table below:

| Technology | Impact on Production | Benefits |

|---|---|---|

| Precision Agriculture | Higher yields through optimized planting | Improved resource management |

| Drones | Real-time monitoring and pest control | Reduced chemical usage |

| Automated Harvesters | Faster harvesting processes | Lower labor costs |

Sustainability Practices: Reducing Waste in the Process

In the heart of a paddy processing plant, the commitment to environmental stewardship is palpable. Unyielding in their quest for efficiency, the plant employs a range of innovative methods designed to minimize waste generation. From the onset of the milling process, each decision aims to contribute positively to the ecosystem. This is achieved through various strategies, such as:

- Byproduct Utilization: The outer husk from the rice is transformed into biomass fuel, reducing reliance on fossil fuels.

- Water Recycling: A sophisticated filtration system allows for the reuse of water during the parboiling and milling phases, ensuring that resources are managed judiciously.

- Packaging Innovations: The plant has introduced biodegradable materials for packaging, replacing conventional plastics with compostable alternatives.

Moreover, the plant has tightly integrated technology to monitor and control waste streams. By utilizing data analytics, it can predict and mitigate waste generation at each stage, from harvesting to final packaging. This is especially important in ensuring the company’s sustainability goals are met. A brief overview of the key metrics tracked includes:

| Metric | 2022 | 2023 Goal |

|---|---|---|

| Total Waste Produced | 500 tons | 300 tons |

| Water Recycled | 60% | 80% |

| Biodegradable Packaging Usage | 35% | 100% |

As this paddy processing facility champions sustainable practices, its approach serves as a blueprint for others in the agricultural sector, combining environmental responsibility with operational excellence.

Market Trends and Future Opportunities for Paddy Processing Plants

The landscape of paddy processing is evolving, driven by rising global demand for rice and innovative processing technologies. As nations increasingly focus on food security, the interest in efficiently converting paddy to high-quality rice continues to surge. Market analysts are observing notable trends, including:

- Automation and Technology Integration: Advanced milling machines and AI-driven processing techniques are enhancing yield and efficiency.

- Health-Conscious Consumer Preferences: There is a growing demand for organic and fortified rice, pushing processors to adapt their offerings.

- Sustainability Initiatives: Eco-friendly practices are becoming crucial, as consumers favor brands that prioritize environmental responsibility.

Future opportunities are abundant for entrepreneurs and current players in the paddy processing sector. Potential avenues for growth include:

| Opportunity | Description |

|---|---|

| Value-Added Products | Development of rice bran oil and other byproducts can open new revenue streams. |

| Export Markets | Increasing demand in international markets presents a chance for expansion. |

| Research and Development | Investing in R&D can lead to innovative processing methods and improved product quality. |

By staying attuned to these trends and seizing opportunities, paddy processing plants can position themselves strategically for sustained growth in an ever-competitive market.

Wrapping Up

As we step away from the rhythmic hum of machinery and the earthy aroma of freshly processed rice, we are left with a deeper understanding of the intricate journey that each grain undertakes before reaching our plates. The paddy processing plant, often seen as just another cog in the agricultural machine, reveals its profound significance, weaving together tradition and technology in a delicate dance.

From the fields where farmers painstakingly cultivate their crops to the state-of-the-art facilities where grains are transformed into the staple we know and love, this journey is a testament to human ingenuity and resilience. The stories of those who work tirelessly behind the scenes—engineers, laborers, quality control experts—remind us that every meal carries with it a rich tapestry of effort, skill, and dedication.

As we return to our kitchens, let us carry forward the awareness of this journey. Each plate of rice we serve is not just a simple dish; it’s a culmination of a life cycle filled with care, craftsmanship, and community. The next time you savor a bowl of rice, remember that beyond its simplicity lies a world of stories waiting to be told.