In an era where innovation and efficiency drive the agricultural sector, the demand for processing solutions that can maximize productivity is more crucial than ever. Among the cornerstones of food production, rice stands out as a staple for more than half of the world’s population, making its processing a significant aspect of the agricultural landscape. Enter the 2 Ton rice mill plant Project—a well-crafted blueprint designed to transform the way rice is milled, ensuring quality and accessibility for communities and markets alike. This article delves into the intricacies of building a successful rice mill, from the initial concept and planning stages to execution and operation. Whether you are an aspiring entrepreneur, a seasoned investor, or an agricultural enthusiast, this guide aims to provide a comprehensive roadmap that illustrates how leveraging technology and strategic planning can cultivate agricultural success, one grain at a time. Join us as we explore the essential components and best practices for establishing a thriving rice milling enterprise in today’s dynamic agricultural environment.

Blueprint for Setup: Essential Components of a 2 Ton Rice Mill Plant

To embark on the journey of establishing a successful 2 ton rice mill plant, certain fundamental elements must be meticulously integrated into the design and operation. First and foremost, the production line equipment plays a pivotal role in ensuring efficiency. This includes a reliable pre-cleaner to remove impurities, a husker for efficient de-husking, and a grinder to achieve the desired rice texture. Additionally, having a quality casing or machine enclosure can contribute to sound reduction and improve safety standards within the plant. Moreover, investing in an effective packaging unit ensures that the final product is preserved and presented ideally for market distribution.

In tandem with equipment, an organized layout of the plant workflow is vital for streamlined operations. Consideration should be given to utility connections, encompassing electrical, water, and waste disposal systems, which can significantly impact productivity. Beyond mere equipment, a skilled workforce is essential, adept in both machine operation and maintenance. Developing a robust training program will ensure the team is equipped with the necessary expertise. Lastly, establishing a strong quality control process will help monitor each stage of production, safeguarding the standard of the rice being produced.

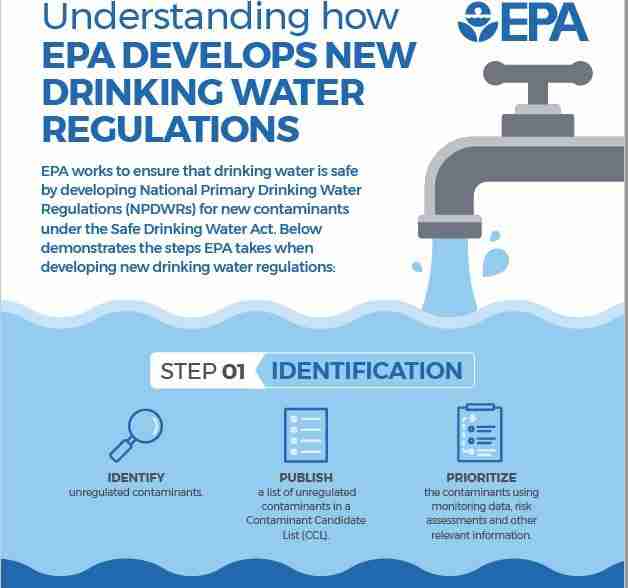

Navigating Regulatory Waters: Ensuring Compliance in Your Rice Mill Project

Launching a rice mill project involves more than just setting up machinery; it requires a thorough understanding of the regulatory landscape to ensure compliance at every stage. As you embark on this venture, consider the following key areas that demand attention:

- Environmental Regulations: Ensure that the mill operates within the permissible limits of emissions and waste disposal, as stipulated by your local environmental authority.

- Health and Safety Standards: Implement workplace safety measures to protect your staff, which may include training and the provision of personal protective equipment.

- Food Safety Compliance: Adhere to food safety regulations, ensuring that all handling and processing of rice meet national hygiene standards.

Establishing a framework for continuous compliance monitoring is essential. You may want to create a regulatory checklist or a compliance calendar to keep track of deadlines and requirements. Consider the following components to aid in your project planning:

| Compliance Area | Action Required | Frequency |

|---|---|---|

| Environmental Impact Assessment | Conduct assessments and submit reports | Annually |

| Health and Safety Audits | Review safety protocols and procedures | Quarterly |

| Food Safety Checks | Inspections and compliance reporting | Bi-annually |

Maximizing Efficiency: Operational Strategies for Optimal Rice Processing

To achieve peak productivity in a rice mill plant, incorporating efficient operational strategies is essential. This begins with streamlining the rice milling process by focusing on proper machinery maintenance and selection. Investing in high-quality milling equipment that has a reputation for reliability ensures minimal downtime while maximizing output. Additionally, training staff in the latest operational techniques can significantly enhance performance, enabling them to optimize each stage of processing. This could include techniques for pre-cleaning, husking, and polishing rice, ensuring that each facet of the operation is executed flawlessly.

Furthermore, implementing advanced technology can revolutionize rice processing efficiency. Integrating automation in areas such as sorting and packaging not only speeds up production but also reduces the risk of human error. Beyond machinery, data analytics can be harnessed to monitor real-time performance, identifying bottlenecks and areas for improvement. Consider the following strategies:

- Regular Equipment Inspection: Schedule routine checks to prevent unexpected failures.

- Adoption of Lean Manufacturing Principles: Streamline workflows to eliminate waste.

- Employee Empowerment: Encourage staff to suggest improvements and participate in decision-making.

| Strategy | Benefits |

|---|---|

| Equipment Upgrades | Increased efficiency, lower breakdown rates |

| Employee Training Programs | Higher productivity, improved job satisfaction |

| Utilization of Automation | Faster processing times, reduced labor costs |

Sustainable Practices: Eco-Friendly Approaches for Long-Term Success in Milling

Implementing eco-friendly practices in the milling industry can pave the way for long-term success while minimizing environmental impact. By focusing on renewable resources and efficient processes, mills can play a pivotal role in sustainable agriculture. Key strategies include:

- Waste Reduction: Embracing zero-waste models by repurposing by-products such as rice husks for energy or as biochar improves efficiency.

- Water Conservation: Utilizing advanced irrigation techniques and water recycling systems can significantly reduce water consumption in processing.

- Energy Efficiency: Incorporating renewable energy sources, like solar or biomass, ensures that the mill operates sustainably without relying heavily on fossil fuels.

- Eco-Friendly Packaging: Shifting to biodegradable or recyclable packaging materials can enhance the mill’s green credentials and appeal to environmentally conscious consumers.

Moreover, adopting sustainable practices not only benefits the environment but also results in operational cost savings. By investing in modern, energy-efficient machinery, mills can reduce energy costs and improve overall productivity. For instance, consider the following table showcasing potential savings from various eco-friendly upgrades:

| Upgrade Type | Initial Investment | Annual Savings |

|---|---|---|

| Solar Energy Installation | $15,000 | $3,000 |

| Water Recycling System | $10,000 | $1,500 |

| Energy-Efficient Machinery | $20,000 | $5,000 |

As the industry evolves, adopting these methods can contribute to a more sustainable future while ensuring that milling operations remain profitable and competitive.

To Wrap It Up

As we conclude our exploration of the “Building Success: A 2 Ton rice mill plant Project Blueprint,” it becomes clear that embarking on such a venture is not merely an investment in machinery, but a commitment to fostering growth and sustainability in the agricultural sector. This blueprint serves as both a roadmap and a beacon for aspiring entrepreneurs eager to elevate their business aspirations.

Through detailed planning and strategic implementation, the potential for success lies within your grasp, ready to be harvested like the grain you aim to process. Remember, each project phase, from the initial groundwork to operational fine-tuning, is an opportunity for learning and development. As you stand on the threshold of this endeavor, envision the impact it could have — not only on your future but on the livelihoods of those in your community.

So, as you plant the seeds of your rice mill project, may they yield a bountiful harvest of success, innovation, and resilience. With diligence and foresight, your journey can inspire others, paving the way for a richer landscape in grain processing and sustainable practices. The blueprint is in your hands; the next step is yours to take.