In a world where breakfast choices are abundant and diverse, few foods have the potential to capture the imagination and ignite the taste buds quite like cereal. But behind every delicious bowl of cereal lies a finely tuned process that transforms grains into the familiar flakes, shapes, and textures that we all know and love. Welcome to the intriguing world of cereal milling, where science, artistry, and tradition converge to create the breakfast staples that fuel our mornings. Join us as we explore the intricate techniques and innovative technologies that go into mastering the art of cereal milling.

Understanding the Importance of Proper Cereal Milling Techniques

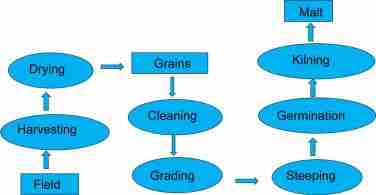

Proper cereal milling techniques are essential for producing high-quality grains that can be used in a variety of food products. By understanding the importance of these techniques, millers can ensure that the final product is not only tasty but also nutritious. The art of cereal milling involves carefully selecting the right grains, cleaning and sorting them, and then processing them through a series of milling machines.

One of the key benefits of using proper cereal milling techniques is that it helps to retain the nutritional value of the grains. When grains are milled correctly, they retain more of their natural vitamins and minerals, making them a healthier choice for consumers. Additionally, milling techniques can also affect the texture and flavor of the final product, making it more appealing to customers. By mastering the art of cereal milling, millers can produce grains that are not only nutritious but also delicious.

Exploring Different Types of Cereal Milling Equipment

When it comes to the art of cereal milling, there are various types of equipment that play a crucial role in the process. Each type of equipment has its own unique features and benefits, making it essential for cereal producers to understand their options and choose the right machinery for their specific needs.

Some of the different types of cereal milling equipment that are commonly used in the industry include:

- Roller Mills: These machines use a series of rollers to crush and grind grains into flour, providing a consistent and uniform texture.

- Hammer Mills: These machines use rotating hammers to pulverize grains, making them ideal for producing coarse flour or cracked grains.

- Stone Mills: These traditional mills use stone grinding wheels to create flour, preserving the natural flavor and nutrients of the grains.

Maximizing Efficiency and Quality in Cereal Milling Operations

Milling grains into cereal products is both a science and an art form. The process involves a delicate balance of maximizing efficiency while maintaining the highest quality standards. One key aspect of achieving this balance is ensuring the milling equipment is properly calibrated and maintained to produce consistent results.

Another crucial factor in cereal milling operations is the selection of the right grains and ingredients. By carefully sourcing high-quality grains and additives, mills can ensure the final product meets customer expectations for taste, texture, and nutritional value. Implementing efficient production processes, such as automated packaging systems and real-time quality control measures, can further optimize efficiency and quality in cereal milling operations.

Key Factors to Consider When Selecting Cereal Milling Machinery

When it comes to selecting the perfect cereal milling machinery, there are several key factors that cannot be overlooked. One of the most important considerations is the type of cereal you will be milling. Different grains require different milling processes, so it is essential to choose machinery that is specifically designed for the type of cereal you will be working with. Another crucial factor to consider is the capacity of the machinery. Depending on the scale of your operation, you will need to select machinery that can handle the volume of cereal you plan to process.

Additionally, the efficiency and energy consumption of the milling machinery are important factors to take into account. Look for machinery that is not only efficient in producing high-quality milled cereal but also consumes energy in a sustainable manner. It is also essential to consider the maintenance and service requirements of the machinery, as well as the availability of spare parts. By carefully evaluating these key factors, you can ensure that you select the ideal cereal milling machinery for your operation.

Future Outlook

In conclusion, the art of cereal milling is a fascinating process that has been perfected over centuries. From the ancient hand mills to the modern industrial machinery, the craft of turning grains into flour is a vital component of our daily lives. Whether you enjoy a simple bowl of cereal in the morning or appreciate the complexity of baking a beautiful loaf of bread, cereal milling plays a key role in creating the foods we love. Next time you sit down to enjoy a meal made with flour, take a moment to appreciate the artistry and skill that goes into each and every grain that goes into the milling process. The history and tradition of cereal milling continue to inspire and amaze us, showcasing the ingenuity and creativity of humanity in transforming something as simple as grains into nourishment for our bodies and souls.