Unlocking the Science: The Art of Cereal Processing

In the vast landscape of food production, where innovation meets tradition, few domains blend the technical with the tactile as seamlessly as cereal processing. Every morning, millions of individuals pour their favorite grains into bowls, accompanied by the satisfying sound of crunch and the promise of nourishment. Yet, behind these seemingly simple acts lies a complex interplay of science and artistry—an intricate dance between nature’s bounty and the craft of food engineering. This article invites you on a journey to explore the fascinating world of cereal processing, uncovering the methods that transform raw grains into the beloved cereals adorning breakfast tables worldwide. From the field to the factory and finally to your bowl, we will delve into the processes that not only look to preserve the integrity of the grain but also enhance its flavor, texture, and nutritional value. Join us as we unlock the secrets behind the processing techniques that make cereal not just a meal, but a cornerstone of our daily lives.

Exploring Grain Selection and Quality Standards

In the realm of cereal processing, the selection of grain plays a pivotal role in determining both the final product and its quality. Each type of grain possesses unique characteristics that influence not just taste, but also texture and nutritional value. Key aspects to consider when selecting grain include:

- Grain Type: Different grains like wheat, barley, and corn come with distinct attributes.

- Harvest Timing: The optimal time for harvesting grains can significantly impact their quality.

- Moisture Content: Proper moisture levels are crucial in preventing spoilage and ensuring a longer shelf life.

Quality standards are essential benchmarks in the cereal industry, guiding producers in achieving consistency and excellence in processing. These standards encompass various metrics, such as grade and purity, which dictate the usability of the grain. A comparative overview of commonly used quality standards can highlight industry expectations:

| Quality Standard | Description | Typical Use |

|---|---|---|

| US No. 1 | Highest quality, minimal defects | Premium products |

| US No. 2 | Good quality with some permissible defects | Baking and brewing |

| US No. 3 | Acceptable quality with several defects | Animal feed |

The Role of Extrusion in Cereal Texture and Flavor

Extrusion is a transformative process that significantly enhances the texture and flavor profiles of cereals. By subjecting raw ingredients to high temperatures and pressures, this method creates a unique environment where starches gelatinize and proteins undergo denaturation. The result is a delightful variety of textures, ranging from crispy to puffy, each with its own distinct mouthfeel. The controlled conditions of extrusion enable manufacturers to manipulate critical factors, including moisture content, temperature, and pressure, to achieve their desired characteristics. This precision allows for a wide array of cereal shapes and forms, transforming base ingredients into enticing breakfast options that appeal to diverse consumer preferences.

Moreover, extrusion impacts the flavor release and sensory experience of cereals. During the process, the rapid heating and shear forces can activate flavor compounds, enhancing their volatility and promoting a more pronounced taste sensation upon consumption. The ability to incorporate various flavoring agents during extrusion contributes to the innovation of unique cereal varieties. Manufacturers can tailor their products by incorporating natural flavors, sweeteners, and even functional ingredients like vitamins and minerals. This flexibility not only creates a rich palette of flavors but also supports the growing demand for health-conscious alternatives in the cereal market.

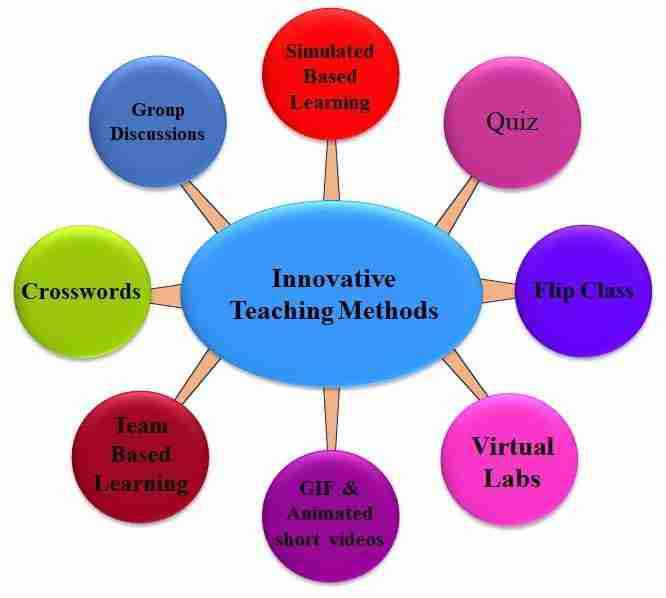

Innovative Techniques in Nutritional Fortification

Cereal processing has reached new heights with the introduction of groundbreaking methods aimed at enhancing the nutritional profile of breakfast staples. These innovative techniques not only fortify cereals but also offer consumers a more balanced diet. Some key approaches include:

- Microencapsulation: This technique involves encapsulating nutrients within a protective coating, ensuring their stability and promoting gradual release during digestion.

- Extrusion Technology: A process where cereals are cooked under high temperature and pressure, allowing for improved texture and nutrient retention.

- Fermentation: Utilizing beneficial microbes to enhance digestibility and increase bioavailability of vitamins and minerals.

Additionally, the use of tailored nutrient blends is revolutionizing cereal formulation. Manufacturers are now able to create custom mixes that cater to specific dietary needs, including:

| Nutrient | Benefits |

|---|---|

| Iron | Essential for blood health and energy levels. |

| Vitamin D | Supports bone health and immune function. |

| Folic Acid | Crucial for cell division and vital during pregnancy. |

These advances in nutritional fortification not only enrich the cereals themselves but also empower consumers to make healthier choices. By integrating these techniques into cereal production, we can meet the diverse dietary needs of today’s populations while promoting overall well-being.

Sustainable Practices for Eco-Friendly Cereal Production

In the quest for a sustainable future, cereal production is stepping up to the plate with innovative practices that benefit both the environment and consumers. By focusing on regenerative agriculture, farmers can improve soil health and biodiversity while reducing their carbon footprint. Techniques such as crop rotation, cover cropping, and no-till farming are gaining traction, leading to healthier ecosystems and more resilient crops. In addition, using integrated pest management reduces the need for synthetic chemicals, allowing for a healthier balance between pest control and environmental preservation.

Moreover, the cereal processing industry is embracing sustainable sourcing and transparent supply chains to ensure that ingredients are acquired responsibly. Labels are no longer just marketing tools; they can now reflect a commitment to ecological and social responsibility. Consumers are increasingly looking for products that feature:

- Organic certification to guarantee no harmful pesticides were used.

- Fair Trade practices that support ethical working conditions for farmers.

- Local sourcing to reduce carbon emissions associated with transportation.

| Practice | Benefit |

|---|---|

| Crop Rotation | Enhances soil fertility and breaks pest cycles |

| Cover Cropping | Reduces soil erosion and improves moisture retention |

| No-Till Farming | Promotes soil health and decreases carbon emissions |

In Retrospect

As we conclude our journey through the intricate world of cereal processing, it becomes clear that this seemingly simple breakfast staple is anything but ordinary. Behind each crispy flake and puffy puff lies a fascinating interplay of science and art, where meticulous techniques and innovative technologies come together to transform raw grains into the cereals we love. By unlocking the secrets of these processes, we not only gain a deeper appreciation for what fills our bowls each morning but also recognize the importance of sustainability and health in cereal production. As we move forward, may we carry this knowledge with us, fostering a greater connection to our food and the complex science that makes it possible. Whether you savor your cereal with milk, yogurt, or on the go, let each bite remind you of the artistry behind the process, encouraging us all to cherish the craft that shapes our daily rituals.