In the quiet cacophony of the breakfast table, where the sun’s early rays dance upon glossy surfaces, an unassuming bowl of cereal stands as a culinary marvel. Often taken for granted, this everyday staple is the result of an intricate journey that begins in sun-kissed fields and culminates in our kitchens. “From Grain to Bowl: The Science of Cereal Processing” delves into this transformative odyssey, unraveling the fascinating interplay of nature and technology that converts humble grains into colorful flakes and puffed morsels. In a world increasingly captivated by the stories behind our food, we invite you to explore the meticulous processes that shape the cereals we cherish, revealing the science and artistry that combine to make every bite a blend of heritage and innovation. Join us on this exploration of the unseen forces at work, as we uncover how grains traverse the labyrinth of processing to become the cherished breakfast choice for millions.

Understanding Grain Types and Their Nutritional Profiles

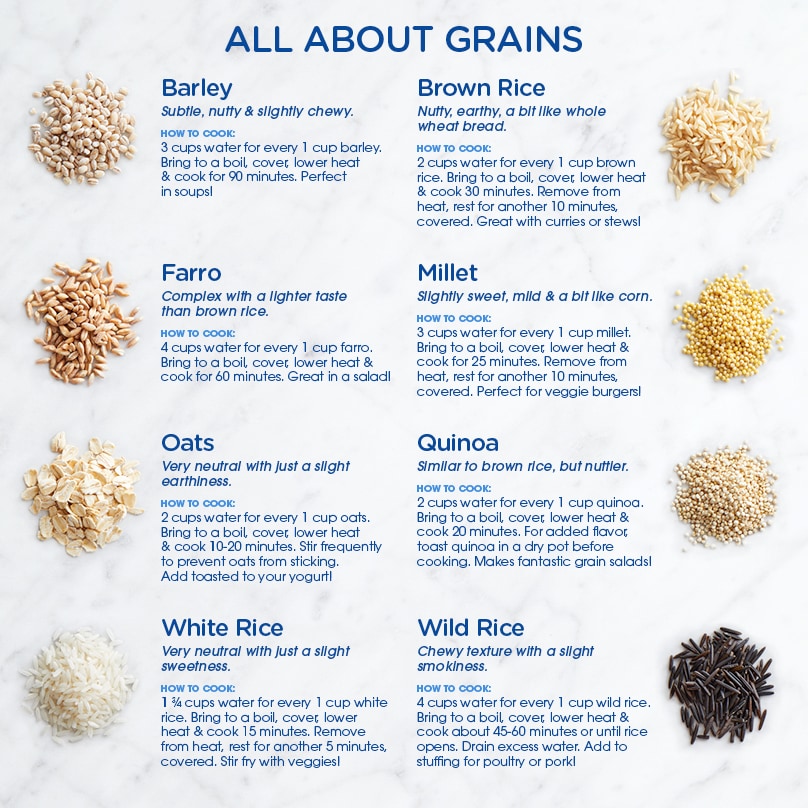

Grains are a staple in the human diet and come in various types, each contributing uniquely to our health and nutrition. Understanding these grain types is essential for making informed dietary choices. Some common grains include:

- Wheat: Rich in carbohydrates and fiber, wheat also contains vital B vitamins, making it a quick energy source.

- Rice: A gluten-free option, rice provides a good source of energy and is easily digestible, particularly white rice.

- Oats: High in soluble fiber, oats can help reduce cholesterol levels and support digestive health.

- Barley: Known for its high fiber content and beneficial beta-glucans that can enhance heart health.

- Quinoa: A complete protein source, quinoa is packed with essential amino acids and is a great choice for plant-based diets.

The nutritional profiles of these grains can significantly impact health outcomes. For instance, while white rice is often criticized for its low nutrient density, brown rice retains its bran and germ, providing a richer array of nutrients such as magnesium and phosphorus. The following table highlights some of the key nutritional components found in various grains:

| Grain | Carbohydrates (g) | Protein (g) | Fiber (g) | Key Nutrients |

|---|---|---|---|---|

| Wheat | 76 | 13 | 2.7 | B vitamins, Iron |

| Rice (White) | 80 | 7 | 0.4 | Low nutrient density |

| Oats | 66 | 16.9 | 10.6 | Magnesium, Antioxidants |

| Barley | 73 | 12.5 | 17.3 | Beta-glucans, Selenium |

| Quinoa | 64 | 14 | 7 | Complete protein, Iron |

The Journey of Grains: Processing Techniques Explained

The transformation of grains into the cereals we enjoy begins with careful selection and specialized processing techniques. Each type of grain—be it wheat, corn, or rice—requires unique handling to maximize its nutritional potential and flavor. The primary processing steps typically include cleaning, hulling, and milling. During cleaning, grains are freed from impurities, such as dirt and stones, ensuring a safe product. Hulling involves removing the inedible outer layers, allowing the nutrient-rich inner part to shine through. milling grinds the cleaned and hulled grains into flour or meal, which serves as the foundation for various cereal products.

What follows is an intricate dance of further processing techniques designed to enhance texture and taste. Common methods include toasting, flaking, and extruding. For example, flattening grains into flakes through a steam-and-press method utilizes heat to develop rich flavors and crispy textures. On the other hand, extrusion merges heat and pressure to create puffed cereals, shaping them into fun forms while locking in nutrients. The combination of these processing techniques not only preserves the integrity of the grains but also transforms them into delightful breakfast options that grace our tables every morning.

| Processing Technique | Description | Benefits |

|---|---|---|

| Cleaning | Removal of impurities | Ensures safety and quality |

| Hulling | Removal of outer layers | Enhances nutritional value |

| Milling | Grinding into flour or meal | Provides versatility in cooking |

| Toasting | Subjecting grain to heat | Develops rich flavors |

| Extruding | Combining heat and pressure | Creates unique shapes and textures |

Enhancing Flavor and Texture: The Role of Additives in Cereal Production

In the world of cereal production, the quest for enhanced flavor and texture often leads manufacturers to incorporate a variety of additives. These ingredients, which range from natural to synthetic, play a crucial role in creating an appealing and enjoyable breakfast experience. Among the most notable additives are flavor enhancers, which elevate the taste profile of the final product. For instance, vanilla extract, chocolate flavoring, and fruit powders can transform a bland base into a delicious concoction that tempts the palate. Textural additives such as crunch enhancers and stabilizers also contribute significantly, ensuring that cereals maintain their desired crunch while remaining fresh and appetizing. The careful balance of these components is essential; too much of an additive can overpower the natural flavors of the grains, while too little may lead to a lackluster product.

Additionally, the incorporation of fiber and protein additives not only enriches the nutritional profile of cereals but also enhances the mouthfeel, providing consumers with a sense of satisfaction. For example, adding wheat bran or soy protein isolate can create a heartier texture, appealing to health-conscious individuals. These functional ingredients are often carefully selected to resonate with current trends in dietary choices and consumer preferences. Below is a concise overview of some common additives used in cereal production:

| Additive Type | Purpose | Examples |

|---|---|---|

| Flavor Enhancers | Boost flavor profile | Vanilla Extract, Cocoa Powder, Natural Fruit Flavors |

| Textural Additives | Maintain crunch and stability | Crunch Enhancers, Starch, Gums |

| Nutritional Additives | Improve health benefits | Protein Isolate, Fiber, Omega-3 Fatty Acids |

Sustainable Practices in Cereal Manufacturing: Recommendations for a Greener Future

Embracing eco-friendly manufacturing techniques is essential in today’s cereal production landscape. By adopting sustainable sourcing methods, manufacturers can significantly reduce their environmental impact. This involves prioritizing grains that are grown using sustainable farming practices, such as crop rotation and organic farming. Additionally, investing in energy-efficient technologies during processing can lower carbon emissions, while also decreasing energy costs. Other pivotal steps include minimizing waste through efficient inventory management and exploring opportunities for by-product utilization to ensure that every grain is maximally beneficial.

To operationalize sustainability effectively, companies can implement a range of practices, creating a ripple effect throughout the supply chain. Key recommendations include:

- Water Conservation: Implementing closed-loop water systems in processing plants to recycle and reuse water.

- Packaging Innovations: Transitioning to biodegradable or recyclable packaging materials to reduce landfill waste.

- Local Sourcing: Partnering with nearby farms to lessen transportation emissions and support local economies.

- Employee Training: Educating staff on sustainable practices and their importance to foster a culture of environmental responsibility.

By integrating these practices, manufacturers not only enhance their eco-credentials but also align with global movements towards sustainability in food production. Below is a comparison of the traditional versus sustainable practices in cereal manufacturing:

| Aspect | Traditional Practices | Sustainable Practices |

|---|---|---|

| Sourcing | Large-scale monoculture | Diverse crop rotation |

| Energy Use | High energy consumption | Energy-efficient machinery |

| Water Usage | Water-intensive processes | Water recycling techniques |

| Waste Management | High waste generation | By-product recovery systems |

Insights and Conclusions

As we reach the end of our journey from grain to bowl, it’s clear that the world of cereal processing is a fascinating intersection of nature and technology. What begins as humble grains, nurtured by sun and soil, transforms through sophisticated processes into the breakfast staple we cherish. The meticulous craftsmanship of milling, the precision of fortified ingredients, and the art of packaging all come together to create not just a meal, but a ritual that fuels our days.

Understanding the science behind cereal processing not only deepens our appreciation for this daily staple but also encourages us to think critically about our food choices. From nutritional innovations to sustainable practices, the story of cereal is still unfolding. As you pour your next bowl, consider the intricate journey those grains undertook and the science that brought them to your table. Your breakfast is not just food; it’s a product of ingenuity, resilience, and the ongoing quest to nourish our bodies. So, let’s celebrate this fusion of nature and science, one spoonful at a time.