The age-old tradition of maize milling holds a fascinating place in the world of food production. From the humble corn cob to the finely ground flour that graces our tables, the intricate process of transforming maize into a staple ingredient is an artform all its own. In this article, we will explore the rich history, techniques, and cultural significance of maize milling, shedding light on the skill and precision required to produce this essential ingredient. Join us on a journey into the heart of the maize mill, where tradition and innovation intersect to create something truly remarkable.

Understanding the Process of Maize Milling

Maize milling is a process that involves separating the maize kernel into its various components to produce a range of products. The process requires precision and expertise to ensure that each product meets the desired quality standards. One of the key steps in maize milling is cleaning the maize kernels to remove any impurities like dust, stones, or foreign materials.

Once the maize kernels are cleaned, they are then processed through a series of machines that grind, separate, and sift the kernels to produce maize flour, maize grits, and maize meal. These products can be used in a variety of food applications, from making cornbread and tortillas to brewing beer and producing animal feed. The art of maize milling lies in understanding each stage of the process and how to manipulate it to achieve the desired end product.

Optimizing Grinding Techniques for Quality Flour Production

When it comes to maize milling, the key to lies in finding the perfect balance between speed and precision. Using the right combination of mill settings, grinding tools, and monitoring equipment is crucial in achieving the desired flour texture and consistency. By carefully adjusting factors such as moisture content, feed rate, and grinding pressure, millers can ensure that their final product meets the highest quality standards.

One important aspect of optimizing grinding techniques for maize milling is the proper maintenance of grinding equipment. Regular cleaning, sharpening, and calibration of mill components can greatly impact the overall efficiency and quality of flour production. Additionally, implementing regular quality control checks and monitoring the performance of the milling process can help identify any potential issues early on, allowing for adjustments to be made to optimize flour output. By mastering the art of maize milling, millers can consistently produce high-quality flour that meets the demands of their customers and stands out in the market.

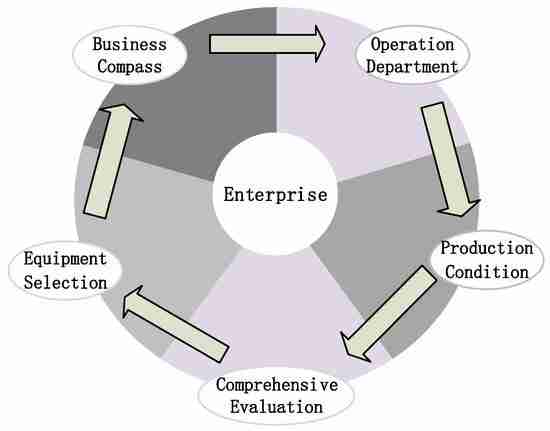

Equipment Selection and Maintenance for Efficient Milling Operations

The success of efficient maize milling operations hinges on the proper selection and maintenance of equipment. Maize milling is not just a process, but an art that requires attention to detail and precision. By carefully choosing the right equipment and keeping it well-maintained, milling operations can achieve optimal efficiency and productivity.

When it comes to equipment selection, consider factors such as capacity, power consumption, and ease of maintenance. Investing in high-quality milling equipment will pay off in the long run by ensuring consistent and reliable performance. Regular maintenance, including cleaning, lubricating, and inspecting equipment, will help prolong its lifespan and prevent costly breakdowns. By prioritizing equipment selection and maintenance, maize milling operations can elevate their efficiency and output to new heights.

Innovative Strategies for Enhancing Maize Milling Proficiency

When it comes to enhancing maize milling proficiency, thinking outside the box is key. One innovative strategy is to invest in state-of-the-art milling equipment that can help streamline the milling process. Modern machines equipped with advanced technology can increase efficiency and output, ultimately leading to higher profitability.

Another creative approach is to diversify the products derived from maize milling. By exploring different uses for maize flour, such as in the production of snacks, beverages, or even cosmetics, millers can tap into new markets and expand their customer base. This kind of versatility not only adds value to the business but also keeps it ahead of the competition.

In Conclusion

As we come to the end of our exploration of the art of maize milling, we hope you have gained a deeper appreciation for this ancient practice that continues to shape cultures and cuisines around the world. From the traditional methods passed down through generations to the modern technology that allows for greater efficiency and precision, maize milling truly is a blend of art and science. So the next time you enjoy a fresh tortilla or a steaming bowl of grits, take a moment to remember the skill and dedication that goes into each kernel of maize that reaches your plate. Thank you for joining us on this journey through the world of maize milling.