Unlocking Grain: The Art and Science of Cereal Milling

In the world of food craftsmanship, few processes are as intricate and impactful as cereal milling. It is a delicate dance between tradition and innovation, where ancient techniques meet modern technology to transform humble grains into essential ingredients that nourish millions. As the foundation for everything from morning oatmeal to artisanal bread, milling is both an art and a science, requiring an understanding of grain properties, machinery, and the physical processes that unlock the grains’ potential.

This article delves into the fascinating world of cereal milling, exploring the methods that have evolved over centuries, the technological advancements that have revolutionized the industry, and the meticulous care that goes into producing high-quality flour. From the farmer’s field to the millstone, we will uncover the magic that turns grains into culinary staples, and highlight the skilled artisans who safeguard this grain-to-grain knowledge. Join us as we unlock the secrets behind cereal milling, revealing the true essence of this time-honored practice that continues to shape our diets and cultures.

The Historical Journey of Cereal Milling and Its Evolution

The journey of cereal milling dates back thousands of years, rooted in human innovation and necessity. In ancient civilizations, grains were transformed into flour using simple stone tools, such as mortars and pestles. These rudimentary techniques gradually evolved as societies advanced, leading to the introduction of the watermill in ancient Greece and Rome around the 1st century BC. This innovation not only increased efficiency but also paved the way for larger-scale production. The shift from manual to mechanized milling marked a significant turning point, as it allowed for a more consistent and finer texture of flour, transforming the culinary landscape and enabling the development of new recipes and baked goods.

As time progressed, milling technology continued to evolve. By the 19th century, the rise of steam power and the industrial revolution catalyzed innovations that reshaped the milling industry. Roller mills replaced traditional stone mills, introducing a more efficient grinding method that produced finer flour with improved quality. The introduction of sifter machines allowed for the separation of various flour grades, catering to specific baking needs. Today, milling has entered a new era with technology such as computerized control systems and automation, enhancing precision and efficiency. The modern milling process now encompasses sustainable practices and a focus on whole grain products, reflecting a growing awareness of health and nutrition.

| Period | Key Development | Impact |

|---|---|---|

| Ancient Civilizations | Use of stone tools | Basic grain processing |

| 1st Century BC | Introduction of watermills | Increased efficiency |

| 19th Century | Advent of roller mills | Finer flour production |

| Present Day | Automation and sustainability | Precision milling and health focus |

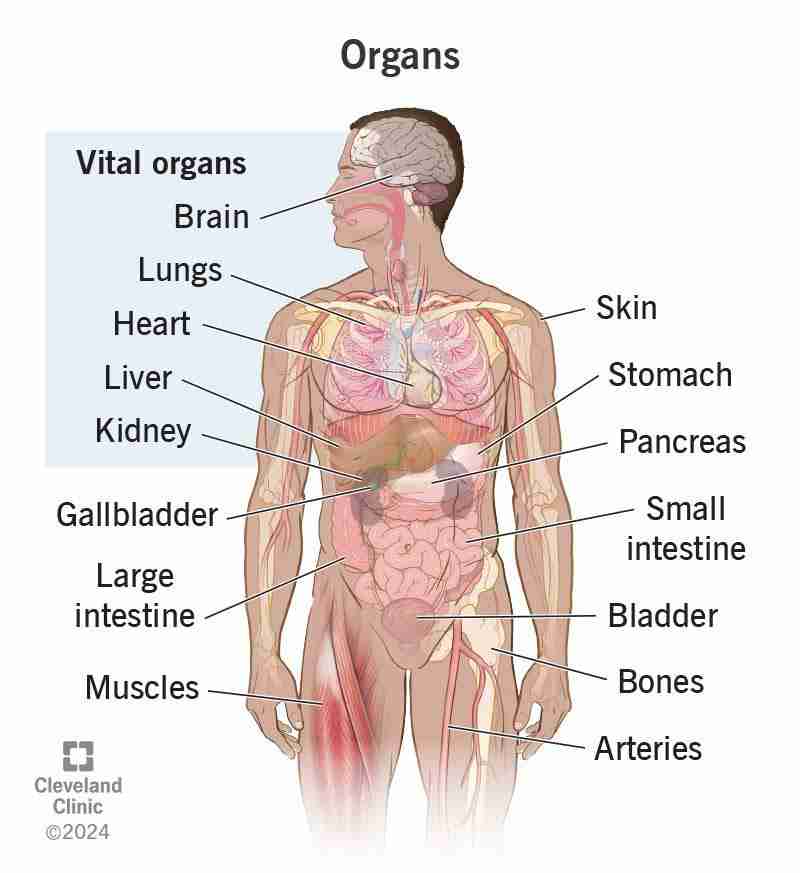

Understanding the Anatomy of Grains for Optimal Milling Techniques

The journey from whole grains to finely milled flour begins with a profound understanding of the underlying anatomy of grains. Each grain has three fundamental layers: the bran, endosperm, and germ. The bran, the outer shell, is rich in fiber, vitamins, and antioxidants, serving as a protective layer. The endosperm, the largest part of the grain, contains mostly starch and some proteins, making it the primary source of energy. the germ, while the smallest part, encapsulates vital nutrients and oils essential for growth. Recognizing these components is crucial for applying optimal milling techniques that preserve nutritional value while achieving desired textures.

A proficient miller must assess the characteristics of various grains—hard wheat, soft wheat, oats, and barley—each requiring unique milling methods for ideal results. The choice of milling technique, whether stone milling, roller milling, or hammer milling, can significantly affect the final product’s quality. Factors such as moisture content, grain hardness, and desired flour extraction rate come into play. To tailor the milling process efficiently, consider the following key attributes of grain anatomy:

- Moisture Content: Affects grinding efficiency and flour yield.

- Hardness: Influences milling technique—harder grains require more energy.

- Oil Content: Present in the germ; high oil levels can lead to rancidity.

| Grain Type | Ideal Milling Technique |

|---|---|

| Hard Wheat | Roller Milling |

| Soft Wheat | Stone Milling |

| Oats | Hammer Milling |

| Barley | Stone Milling |

Innovative Milling Technologies Enhancing Quality and Efficiency

In the ever-evolving landscape of cereal milling, cutting-edge technologies are paving the way for groundbreaking enhancements in both quality and efficiency. Modern milling systems now integrate advanced automation, real-time data analytics, and artificial intelligence, which allow millers to monitor conditions and adjust processes proactively. These innovative approaches not only streamline operations but also contribute to more sustainable practices in grain processing. Key features of these technologies include:

- Precision Milling: Utilizing laser scanning and smart sensors, millers can achieve exact grain size reductions, which is essential for maximizing end-product quality.

- Energy Efficiency: New milling machinery is designed to consume less energy, reducing both operational costs and environmental impact.

- Quality Control: Automated systems inspect and sort grains at every stage, ensuring only the best raw materials enter the milling process.

- Data-Driven Decisions: Advanced software enables millers to analyze production data, leading to continuous improvements in efficiency and product consistency.

Furthermore, the integration of eco-friendly practices within these innovative milling technologies has emerged as a key focus. This includes converting by-products into valuable materials, reducing waste, and sourcing grains sustainably. To illustrate the impact of these advancements, consider the following table showcasing improvements in milling efficiency and product outcomes:

| Technology | Outcome | Improvement |

|---|---|---|

| Automated Sorter | Higher Quality Flour | 20% Reduction in Defects |

| Energy-Efficient Mill | Lower Energy Consumption | 30% Savings |

| Real-Time Analytics | Optimized Production Workflow | 15% Increased Throughput |

As these technologies continue to evolve, they promise to not only elevate the standard of milling practices but also align with global demands for sustainability and quality enhancement. In this way, the art and science of cereal milling are transformed into a refined process driven by innovation and efficiency.

Sustainability Practices in Cereal Processing and Their Impact on the Industry

In the realm of cereal milling, sustainability has emerged as a cornerstone for practitioners aiming to enhance efficiency while minimizing environmental footprints. By adopting innovative practices, milling operations are not only improving their output but also aligning with global efforts to foster ecological balance. Key strategies include:

- Incorporating energy-efficient machinery that reduces electricity consumption.

- Implementing water recycling systems to minimize waste in processing plants.

- Utilizing organic materials for packaging to reduce plastic usage.

These practices are proving instrumental in achieving both economic viability and social responsibility. Furthermore, they foster a more resilient supply chain, essential for addressing the growing demand for transparency in food production. Through advanced technologies, such as precision milling and digital monitoring, companies are not only optimizing yield but also improving the quality of the end products.

| Sustainability Initiative | Impact on Milling |

|---|---|

| Energy-efficient machinery | Reduces operational costs and carbon footprint |

| Water recycling | Conserves resources and protects local water sources |

| Organic packaging | Enhances brand image and attracts eco-conscious consumers |

Crafting a sustainable future in cereal processing not only helps the environment but also leads to innovations that enhance market competitiveness. As industry players continue to prioritize sustainability, the positive ripple effects will empower communities and contribute to a healthier planet.

To Conclude

As we draw the curtain on our exploration of cereal milling, we find ourselves standing at the intersection of art and science—a place where grains transform into the foundational ingredients of our daily sustenance. The meticulous process of unlocking grain, from its cultivation in sun-kissed fields to its journey through innovative milling techniques, reveals a narrative rich in tradition and cutting-edge technology.

The miller’s craft, steeped in history, connects generations, blending age-old techniques with modern advancements that ensure not just efficiency, but also the preservation of flavor, nutrition, and sustainability. Each particle of flour tells a story—a story of soil, sun, and skill, meant to nourish and inspire our collective culinary ventures.

As we consider the intricate balance of these elements, we recognize that the world of milling is not merely about conversion but about creativity, heritage, and the relentless quest for quality. Whether it’s a rustic loaf of bread or a delicate pastry, the essence of what we create is deeply tied to the grains that started it all. Let’s celebrate this intricate process and continue to appreciate the unsung heroes behind the scenes, unlocking the potential of grains that feed our bodies and fuel our imaginations.