In the heart of our everyday breakfasts lies a complex and fascinating process that often goes unnoticed: the journey of grain from field to bowl. “Uncovering the Secrets of Cereal Milling: A Grain’s Journey” delves into the intricate world of cereal milling, where the humble grain undergoes a remarkable transformation. This journey isn’t just about turning wheat, corn, or oats into flour or cereal; it’s a dance of agriculture, technology, and craftsmanship that has evolved over centuries. By shedding light on the various stages of milling, from harvest to processing, we invite you to explore the fascinating interplay between nature and innovation, revealing how each kernel’s story is crafted into the nourishing staples we often take for granted. Join us as we unravel the layers of this essential industry, where tradition meets modernity, and discover the secrets that drive our daily sustenance.

Understanding the Milling Process: From Field to Flour

The journey from field to flour encompasses an intricate dance of nature and technology, transforming humble grains into the vital staple we rely on. Initially, grains like wheat, barley, and corn are harvested at their peak ripeness, their hard shells protecting the precious kernels inside. Once collected, the grains undergo a meticulous cleaning process to eliminate impurities such as dirt, stones, and leftover chaff. This preparation ensures that only the highest quality grains proceed to milling. Key steps in this phase include:

- Sorting: Categorizing grains based on size and quality.

- Cleaning: Removing external contaminants through air and water currents.

- Conditioning: Adjusting moisture levels to enhance milling efficiency.

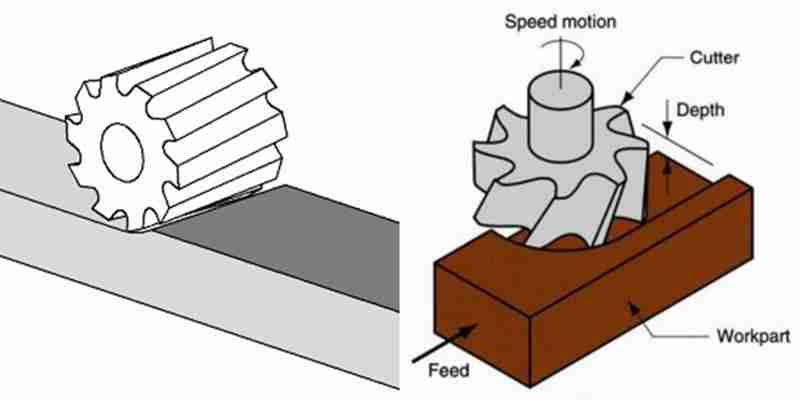

Once the grains are cleaned and conditioned, they move to the milling stage, where they are broken down into flour through a series of grinding and sifting processes. Milling utilizes a combination of mechanical forces to crush, grind, and sift the grains, separating the endosperm from the bran and germ. The result is various flour types, each with unique characteristics and uses. The milling process can be summarized in the following stages:

| Stage | Description |

|---|---|

| Grind | Crushing grains to release their floury content. |

| Sift | Separating fine flour from coarser particles. |

| Blend | Combining various flours for desired properties. |

The Role of Technology in Modern Cereal Milling

The advent of technology has revolutionized the world of cereal milling, transforming traditional practices into sophisticated processes that enhance both efficiency and quality. Today, modern milling employs advanced machinery designed to maximize yield while minimizing waste. Key innovations such as automated control systems, precision milling equipment, and state-of-the-art cleaning technologies work in harmony to ensure the grains undergo a meticulous transformation. This meticulous process not only preserves the nutritional integrity of the grains but also caters to the diverse needs of the market, producing various flour grades suited for different culinary applications.

Moreover, the integration of data analytics and smart sensors plays a pivotal role in ensuring consistency and quality in the milling process. Smart sensors monitor moisture levels, particle size, and temperature, ensuring that each batch meets high standards. The use of predictive maintenance techniques helps milling facilities preempt equipment failures, reducing downtime and maintaining a seamless workflow. Innovations in milling technology have also paved the way for sustainability, as modern mills are increasingly adopting eco-friendly practices, such as energy-efficient machinery and waste recycling systems. This reflects a growing commitment among producers to not only meet consumer demands but also to care for the environment.

| Technology | Function | Benefits |

|---|---|---|

| Automated Control Systems | Streamlines operation | Increases efficiency |

| Smart Sensors | Monitors quality | Ensures consistency |

| Data Analytics | Optimizes processes | Enhances decision-making |

| Eco-friendly Machinery | Reduces waste | Promotes sustainability |

Exploring Quality Control: Ensuring Consistency in Every Batch

As grains transition from farm to table, maintaining their quality is paramount. The milling process incorporates several essential quality control measures to guarantee that every batch meets the highest standards. This involves regular inspection and testing of incoming grains, where millers assess parameters such as moisture content, kernel hardness, and foreign material presence. These assessments help to create a robust foundation for milling, ensuring that the end products retain their nutritional value and flavor integrity.

During milling, continuous monitoring is crucial to detect any fluctuations that may arise in product quality. This can be achieved through various techniques, including:

- Visual inspections: Observing color and texture for inconsistencies.

- Laboratory testing: Analyzing samples for protein content and gluten strength.

- Equipment calibration: Ensuring precision in machinery settings to maintain consistency.

Implementing a structured quality control system not only enhances the efficiency of the milling process but also assures consumers of the consistent quality and safety of the cereals they enjoy. In this journey, every decision made within the mill contributes to the final product’s reliability, solidifying the connection between the grower, the miller, and the end-user.

Sustainability in Cereal Milling: Innovations for a Greener Future

In the realm of cereal milling, sustainability is rapidly becoming a focal point for industry leaders aiming to balance productivity with environmental responsibility. By integrating innovative techniques, the milling process is evolving to minimize waste and lower energy consumption. Modern milling facilities are increasingly utilizing renewable energy sources, such as solar and wind, to power their operations. This shift not only reduces greenhouse gas emissions but also fosters a more resilient supply chain. Key innovations driving this green revolution include:

- Advanced milling technologies that optimize grain extraction and reduce by-products.

- Water recycling systems to ensure minimal water usage throughout the milling process.

- Biodegradable packaging materials to replace traditional plastics, lessening environmental impact.

The commitment to sustainable practices is further reflected in the efforts to establish circular economies within the cereal milling sector. By repurposing milling by-products into animal feed or biofuels, companies can close the loop, transforming waste into valuable resources. Collaboration among stakeholders is essential in creating a more sustainable future, as mills partner with farmers and organizations to implement eco-friendly farming techniques. A glimpse into current sustainable practices in cereal milling can be illustrated as follows:

| Innovation | Impact |

|---|---|

| Energy-efficient milling equipment | Reduces energy consumption by 20% |

| Waste-to-energy systems | Converts by-products into renewable energy |

| Organic farming partnerships | Encourages soil health and biodiversity |

Concluding Remarks

As we conclude our exploration of the intricate world of cereal milling, we find ourselves standing at the intersection of history, science, and artistry. From the humble fields where grains are sown to the cutting-edge mills that transform them, the journey of a grain is nothing short of fascinating. Each step, from harvest to processing, reveals the meticulous care and innovation that define this age-old craft.

In unveiling the secrets behind cereal milling, we’ve not only gained insight into the technical processes but also a deeper appreciation for the countless individuals who contribute to bringing these staples from farm to table. As you pour that first bowl of cereal in the morning or savor freshly baked bread, remember: you’re experiencing the culmination of centuries of knowledge, tradition, and dedication.

So the next time you enjoy a simple breakfast, take a moment to appreciate the complex journey of grains, the unsung heroes of our daily diets. The journey may seem straightforward, but it is rich with stories waiting to be told. As we look to the future, may we continue to honor the past and explore new innovations that will shape the landscape of cereal milling for generations to come. Thank you for joining us on this enlightening expedition.