In the heart of agricultural innovation lies a small yet powerful tool that has the potential to transform traditional practices: the mini rice milling machine. As the world increasingly turns towards efficiency and sustainability in food production, these compact marvels are emerging as essential allies for farmers, entrepreneurs, and food processors alike. With their ability to streamline rice processing—from husking to polishing—mini rice milling machines offer not only versatility but also a sustainable solution that caters to various scales of operation. This article explores the multifaceted benefits of these machines, examining how they unlock new levels of efficiency and adaptability in the rice milling industry, while contributing to greater economic viability in rural communities worldwide. Join us as we delve into the world of mini rice milling and discover how this humble machine is reshaping the future of rice processing.

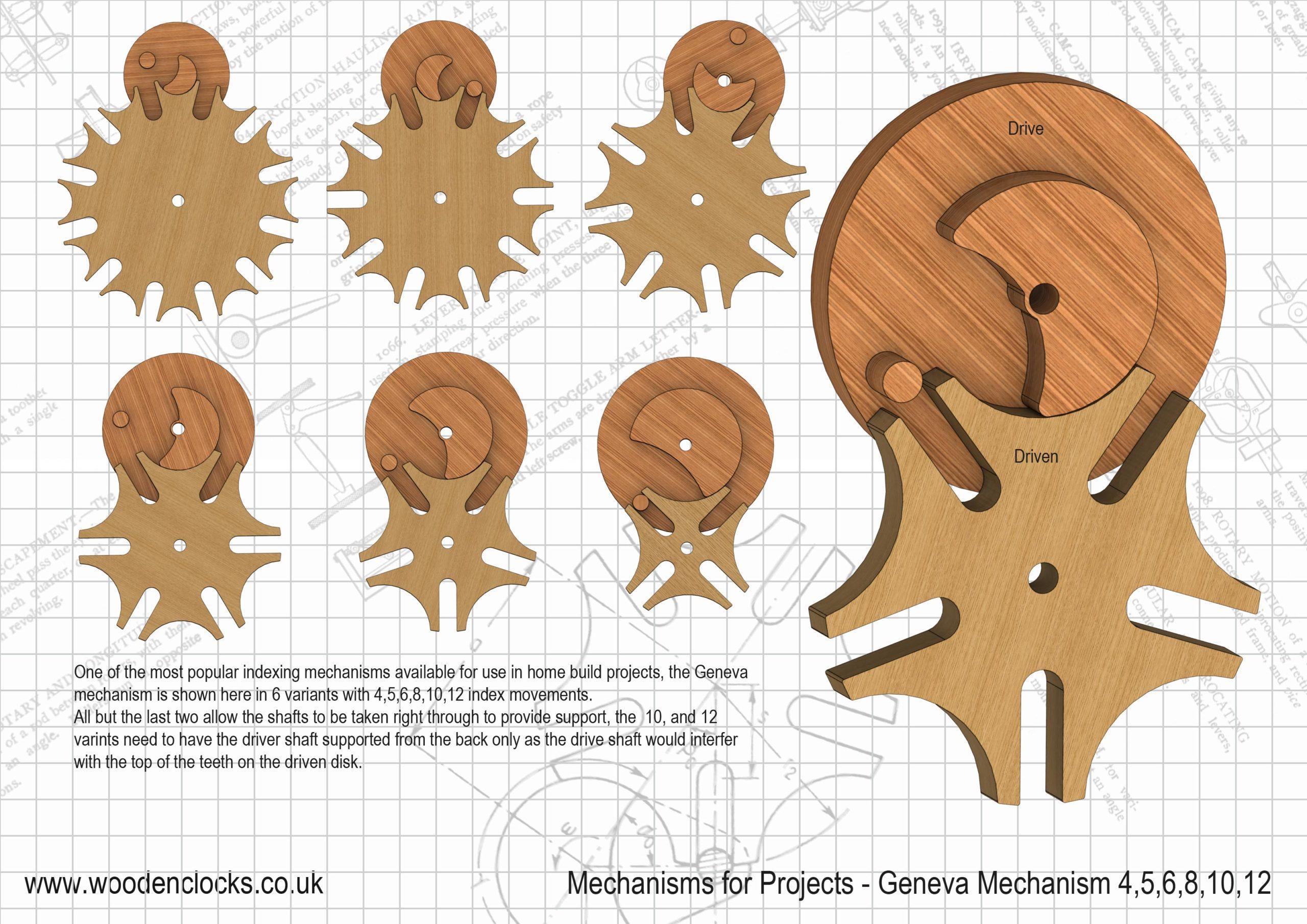

Exploring the Mechanisms Behind Mini Rice Milling Machines

The efficiency of mini rice milling machines lies in their intricate yet straightforward design, which optimizes the milling process. At the heart of these machines is a husk removal mechanism, typically involving a combination of rubber rollers and screens. This system effectively separates the rice grains from the husk without damaging the grains themselves. Following this, the whitening chamber plays a critical role, where the polished rice is achieved through an abrasive process that removes the bran layer. This careful balance between speed and gentleness is vital in preserving the quality of the final product.

Moreover, mini rice milling machines incorporate advanced features that enhance usability and efficiency. For instance, many models are equipped with user-friendly interfaces that allow for easy adjustments in milling parameters, ensuring that users can achieve their desired rice quality with minimal effort. Efficiency is further augmented by components such as self-cleaning systems and integrated dust collectors, which minimize maintenance needs and improve the working environment. These innovations collectively contribute to making mini rice milling machines an essential tool in both small-scale and commercial rice production settings.

The Benefits of Compact Design for Small-Scale Farmers

Compact design in mini rice milling machines plays a pivotal role for small-scale farmers, enhancing both operational efficiency and productivity. These machines are tailored to fit limited spaces while still delivering big performance. By taking up minimal floor space, farmers can optimize their workspace, allowing more room for other essential activities or equipment. Flexibility is key; small-scale farmers can easily relocate these machines as needed, adapting to changing needs or conditions without significant hassle. Additionally, many compact models are designed with user-friendly features, enabling farmers to operate them with minimal training, thus reducing downtime and increasing productivity.

Moreover, compact milling machines often come with a variety of features that cater specifically to the needs of small operations. They not only reduce the physical footprint of milling processes but also require less energy and resources, aligning with sustainable farming practices. Here are some notable advantages:

- Cost-Effective: Lower initial investment and reduced operational costs.

- Energy Efficient: Consumes less power than traditional larger machines.

- Easy Maintenance: Simplified design leads to easier upkeep.

- Enhanced Mobility: Can be easily moved or transported when needed.

the integration of compact designs in rice milling technology not only eases the logistics of small-scale farming but also enhances efficiency, making it a crucial aspect of modern agricultural practices. Such innovations allow farmers to meet both local and broader market demands while promoting sustainability and resource optimization.

Maximizing Output: Tips for Optimal Operation and Maintenance

To ensure that mini rice milling machines consistently deliver peak performance, regular maintenance is essential. Here are some effective practices to consider:

- Daily Cleaning: Dust and rice husk can accumulate quickly. Clean the machine thoroughly at the end of each day to prevent clogs and ensure smooth operation.

- Lubrication: Regularly check and lubricate the moving parts as per the manufacturer’s guidelines to minimize wear and tear.

- Inspection: Conduct weekly inspections of all components, including belts, pulleys, and blades, to identify potential issues before they escalate into costly repairs.

Optimizing production outputs isn’t solely about maintenance; operational techniques can dramatically influence efficiency. Consider implementing these strategies:

| Strategy | Description |

|---|---|

| Staging of Operations | Prepare raw materials in advance to streamline the milling process. |

| Adjusting Settings | Optimize settings based on rice variety for improved yield and quality. |

| Training Workforce | Provide training for operators to better understand machine capabilities and maintenance needs. |

By integrating these maintenance protocols and operational strategies, users can enhance the efficiency and longevity of their mini rice milling machinery, thereby securing a competitive edge in production.

Diverse Applications of Mini Rice Milling Beyond Traditional Uses

Mini rice milling machines have transcended their initial purpose of simply processing rice grains. Today, they serve a multitude of functions that cater to various industries and consumer needs. In rural communities, these machines have become pivotal for local farmers and entrepreneurs, enabling them to diversify their offerings. Beyond milling rice, these machines can be utilized for:

- Milling Other Grains: They can efficiently process millet, wheat, corn, and barley, answering the diverse dietary needs of local populations.

- Producing Rice Flour: This substrate is becoming increasingly popular for gluten-free baking and cooking, expanding culinary possibilities.

- Creating Animal Feed: By milling leftover rice husks or grains, farmers can produce nutritious feed for livestock, enhancing farm sustainability.

- Food Byproducts: They can aid in extracting rice bran oil, a healthy cooking option rich in antioxidants and vitamins.

Moreover, the compact design of mini rice milling machines allows them to fit into small spaces, making them ideal for urban food processing settings. Certain models are now being adapted to support on-demand services like:

- Mobile Milling Services: Entrepreneurs can offer milling directly to consumers at local markets or community events, enhancing farmer-consumer connections.

- Custom Milling Orders: These machines facilitate personalized grain processing, catering to niche markets that prefer specific grain blends or textures.

- Biomass Energy Production: The leftover residues can be converted into biomass energy, promoting eco-friendly practices in agricultural operations.

| Application | Description | Benefit |

|---|---|---|

| Custom Grain Milling | Processing specific grain types for niche markets | Meets customer preferences |

| Animal Feed Production | Utilizing rice byproducts for livestock nutrition | Enhances farm sustainability |

| Mobile Milling Services | On-site milling for local consumers | Connects farmers to consumers |

| Biomass Energy Generation | Converting residues into energy | Supports eco-friendly practices |

Future Outlook

In a world where efficiency and versatility reign supreme, mini rice milling machines are carving a niche that’s both practical and transformative. As we’ve explored throughout this article, these compact powerhouses do more than just streamline rice processing; they embody a blend of innovation and utility that caters to diverse culinary traditions and modern agricultural practices alike.

By maximizing output while minimizing resource consumption, mini rice milling machines are revolutionizing how farmers and businesses approach food production. Whether it’s a small-scale farmer aiming for self-sufficiency or an entrepreneur looking to tap into the rice market, these machines offer solutions that are accessible, efficient, and adaptable to various needs.

As we look to the future, investing in such technology could not only enhance productivity but also contribute to sustainable practices that respect our planet’s resources. The versatility of mini rice milling machines is not just about optimizing processes; it’s about fostering a deeper connection between people, their food, and the land.

As we close this chapter on the potential of mini rice milling machines, we invite you to envision the possibilities within your own endeavors. Efficiency is not just a goal; it’s the key to unlocking a better tomorrow.