In the ever-evolving landscape of agricultural technology, the quest for efficiency remains at the forefront of modern farming practices. Among the innovations that have transformed the rice milling industry, the 4 Ton rice mill plant stands out as a beacon of progress, blending traditional processes with cutting-edge technology. This article delves into the intricacies of the 4 Ton rice mill plant, unveiling how it not only enhances productivity but also preserves the quality of one of the world’s most essential staples. Join us as we explore the unit’s design, functionality, and the significant impact it has on both small-scale farmers and the larger agricultural ecosystem, demonstrating that efficiency is indeed in action.

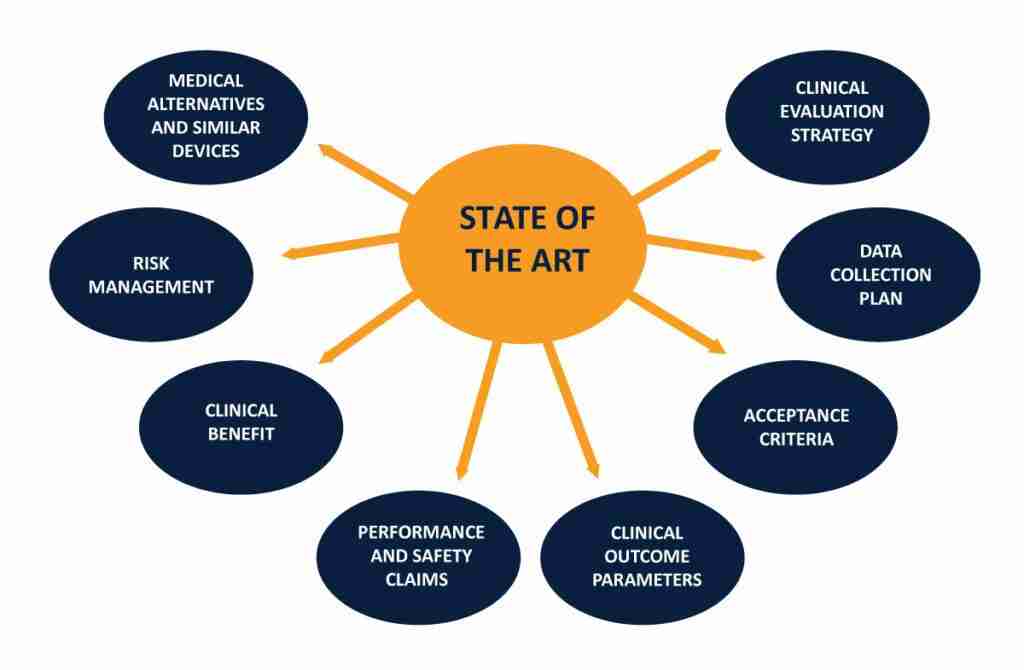

Exploring the State-of-the-Art Technology Behind the rice mill plant

The innovative design of the 4 Ton rice mill plant is a prime example of how technology is transforming agricultural processing. At the core of its functionality lies a fully automated system that enhances efficiency and productivity. This plant integrates several advanced features, including:

- High-Performance Milling Machines: Equipped with precision engineering for optimal rice processing.

- Energy-Efficient Motors: Designed to reduce power consumption without compromising output.

- Automated Cleaning Systems: Ensuring that each grain of rice is free from impurities before milling.

- Real-Time Monitoring: Using IoT technology to analyze and optimize performance in real-time.

Moreover, the plant utilizes sophisticated milling technology that guarantees uniformity in grain size and quality. Each stage of the milling process is meticulously controlled, reducing waste while maximizing yield. A simplified overview of the processing stages includes:

| Processing Stage | Description |

|---|---|

| 1. Cleaning | Removes dirt, stones, and foreign materials. |

| 2. Husking | Separates husk from the paddy rice. |

| 3. Whitening | Removes bran layers to achieve desired whiteness. |

| 4. Polishing | Adds lustre to the rice, enhancing its visual appeal. |

Maximizing Output: Operational Strategies for Enhanced Efficiency

In the pursuit of enhanced efficiency within the 4 ton rice mill plant, implementing robust operational strategies is essential. These strategies not only streamline processes but also enhance productivity by minimizing waste and reducing downtimes. By focusing on a few key elements, such as:

- Automated Processes: Integrating automation in grain handling and milling operations can significantly cut down labor costs while increasing precision.

- Regular Maintenance: Scheduled maintenance of machinery ensures optimal performance and extends the lifespan of equipment.

- Data-Driven Decision Making: Utilizing data analytics to monitor production trends helps in making informed decisions to optimize resource allocation.

- Employee Training: Investing in continuous training and development of personnel fosters a culture of efficiency and innovation.

Moreover, enhancing workflow efficiency can be visually represented through a structured approach that categorizes the processes involved in the rice milling operation. The following table delineates the primary functions within the mill and their corresponding efficiency metrics:

| Process | Efficiency Metric |

|---|---|

| Grain Cleaning | 95% removal of impurities |

| Rice Milling | 85% yield of milled rice |

| Packing | Speed of 500 kg/hour |

These strategies form a cohesive foundation that empowers the rice mill plant to operate at peak efficiency, ultimately maximizing output and boosting profitability. By continually assessing and refining operational protocols, plant managers can ensure sustainable growth and adaptability in an evolving agricultural market.

Sustainability Practices in Rice Milling: Balancing Profit and Environmental Responsibility

In the heart of rice milling, the pursuit of sustainability often clashes with the demands of profitability. Implementing innovative practices in a 4-ton rice mill plant can create a robust harmony between these two vital aspects. By adopting energy-efficient machinery, mills can significantly reduce their carbon footprint and minimize operating costs. Utilizing technologies such as solar-powered systems and waste heat recovery not only enhances operational efficiency but also promotes an eco-friendly business model that stands out in today’s competitive market. Various methods to improve sustainability include:

- Water Management: Recycling and treating water used in the milling process.

- Waste Utilization: Converting by-products into animal feed or compost.

- Packaging Innovations: Using biodegradable materials to minimize plastic waste.

Moreover, a focus on social sustainability ensures that the local farming community benefits from these practices, creating a balanced ecosystem where profit does not come at the expense of people. A collaborative approach can foster better supply chain relationships, ensuring farmers receive fair compensation while consumers gain access to high-quality, sustainably sourced rice. An investment in training and educational programs can empower farmers with knowledge on sustainable practices, creating a ripple effect of positive environmental impact. The following table demonstrates the potential impact of incorporating sustainable practices on various facets of the rice milling process:

| Practice | Environmental Benefit | Economic Advantage |

|---|---|---|

| Energy-Efficient Machinery | Reduced greenhouse gas emissions | Lower energy costs |

| Water Recycling | Conservation of water resources | Reduced water treatment costs |

| Biodegradable Packaging | Less plastic pollution | Attracting eco-conscious consumers |

Cost Analysis and Investment Strategies for Aspiring Rice Mill Entrepreneurs

In embarking on the journey of establishing a rice mill plant, particularly one with a capacity of 4 tons, understanding the intricate details of cost analysis is paramount. Entrepreneurs must take into account the fixed costs associated with starting operations, which include land acquisition, plant installation, and machinery. Furthermore, variable costs, such as labor, raw materials, and maintenance, will continuously affect profitability. A detailed examination of these costs allows potential investors to determine the break-even point, ensuring informed financial planning and sustainable business growth. Consider compiling a list of potential expenses that could impact your budget, such as:

- Machinery and Equipment Costs

- Raw Material Procurement

- Labor Expenses

- Utility Charges

- Transportation Costs

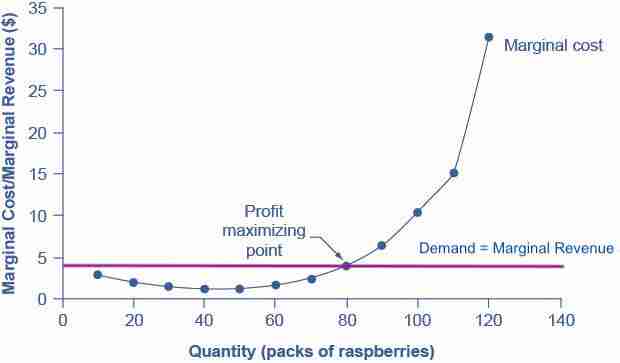

Investment strategies play a critical role in maximizing returns for budding entrepreneurs in the rice milling sector. It is essential for investors to gauge market demand and projected growth in the industry, which can be illustrated through a simple table reflecting potential revenue streams based on various production levels:

| Production Level (Tons) | Estimated Revenue ($) | Projected Profit Margin (%) |

|---|---|---|

| 2 | 10,000 | 20 |

| 4 | 20,000 | 25 |

| 6 | 30,000 | 30 |

By utilizing this data, entrepreneurs can assess the viability of their investment and make strategic choices that enhance the efficiency of their rice mill plant. Combining a thorough market analysis with robust financial planning positions aspiring rice mill owners for long-term success in this competitive landscape.

Wrapping Up

As we draw the curtains on our exploration of the 4 Ton rice mill plant, it becomes evident that this marvel of engineering is more than just a machine; it is a testament to innovation and efficiency in rice processing. With its ability to streamline operations while maximizing output, the plant stands as a beacon for farmers and entrepreneurs alike, showcasing the potential for modern agriculture to thrive in a competitive market.

Through its meticulously designed components, the 4 Ton rice mill plant not only enhances productivity but also champions sustainability by minimizing waste and optimizing resource use. As we continue to navigate the intricate web of food production and supply, embracing such advancements will be key to meeting the rising demand for quality rice and ensuring food security for future generations.

the journey of unveiling this impressive plant is just the beginning. With ongoing technological advancements and a commitment to excellence, the rice milling industry is poised for transformative growth. As stakeholders join forces to harness the power of these innovations, we can look forward to a future where efficiency and sustainability go hand in hand, paving the way for a thriving agricultural landscape. Thank you for joining us in this exploration—may it inspire both reflection and action in the world of rice milling.