In the heart of agricultural innovation lies a staple that has nourished civilizations for centuries: maize. From the vibrant maize fields that stretch across continents to the bustling milling facilities where grains are transformed into flour, the journey of this golden crop is as rich as its nutritional value. “Unlocking the Essentials of Maize Milling: A Comprehensive Guide” ventures into this fascinating world, unraveling the intricacies of the milling process that turns humble kernels into culinary treasures. Whether you are a farmer seeking to optimize your yield, an entrepreneur entering the milling industry, or a culinary enthusiast eager to understand the grain that graces your kitchen, this guide serves as your roadmap. Join us as we explore the essential techniques, technologies, and insights that underpin successful maize milling, unlocking the potential of a crop that is truly the backbone of food security and culture worldwide.

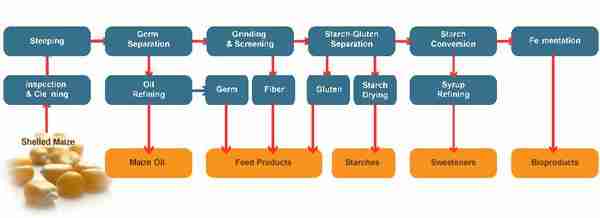

Understanding the Maize Milling Process from Seed to Flour

The journey of maize milling begins long before the kernels reach the mill. First and foremost, the quality of the maize seed is crucial, as it directly impacts the end product. Factors such as seed variety, weather conditions, and soil quality play vital roles in cultivation. Once harvested, the maize undergoes a meticulous cleaning process to remove impurities like dirt, stones, and damaged kernels. This preprocessing ensures that only the highest quality grains proceed to the milling stage.

Once cleaned, the maize is dried to an optimal moisture content level, which is paramount to ensuring the longevity and milling efficiency of the grain. Following drying, the kernels are subjected to grinding, which can be accomplished through various methods including stone milling or roller milling. The selected technique influences the flour’s texture and usability. The final product is then sifted to separate fine flour from coarser particles, and any remaining endosperm or bran can be repurposed for animal feed or other applications. This holistic approach to milling not only maximizes yield but also enhances the nutritional profile of the flour produced.

| Stage | Description |

|---|---|

| Cultivation | Selection of high-quality maize seeds and optimal growing conditions. |

| Harvesting | Collection of mature maize ears for processing. |

| Cleaning | Removal of impurities and damaged kernels. |

| Drying | Adjustment of moisture content for milling efficiency. |

| Milling | Process of grinding to generate different flour textures. |

| Sifting | Separation of flour particles by texture. |

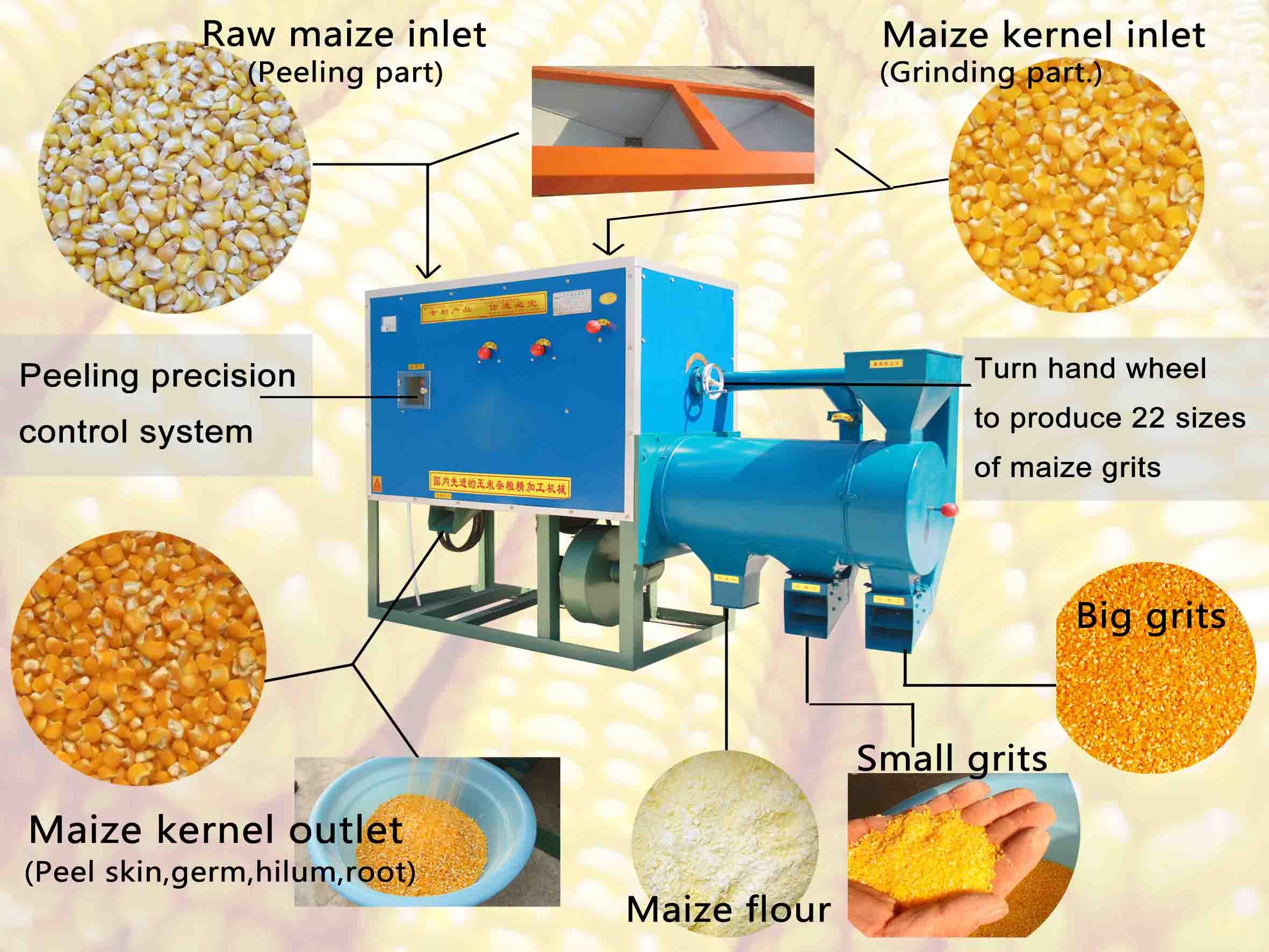

Essential Equipment for Efficient Maize Milling Operations

To achieve optimal performance in maize milling, investing in the right equipment is paramount. Key machinery includes hammer mills, which are essential for grinding maize into flour with consistency and precision. Roller mills follow closely; their design enhances the separation of bran from the endosperm, yielding a finer product. In addition, destoners effectively remove impurities and stones, ensuring that the final product is of high quality. The integration of sifters allows for precise classification of the flour based on particle size, crucial for meeting diverse market demands. Other auxiliary equipment such as cyclones or dust collectors play a significant role in maintaining operational efficiency by managing dust and promoting a cleaner workspace.

Moreover, proper maintenance of milling equipment is non-negotiable. Regular checks on machinery help in identifying wear and tear symptoms early, allowing for timely repairs and minimizing downtime. A proactive approach can be enhanced by utilizing automation systems, which monitor performance metrics and provide real-time feedback. This adds an extra layer of efficiency, helping operators manage processes more smoothly. Here’s a quick overview of equipment to consider for a well-rounded maize milling setup:

| Equipment | Function |

|---|---|

| Hammer Mill | Grinds maize into flour |

| Roller Mill | Separates bran from endosperm |

| Destoner | Removes impurities from grain |

| Sifter | Grades flour by particle size |

| Cyclone | Manages dust and improves airflow |

Quality Control Measures for Optimal Maize Flour Production

Ensuring the highest quality in maize flour production is crucial for both consumer satisfaction and operational efficiency. Implementing stringent quality control measures can significantly enhance the overall output and user trust. Key practices include:

- Raw Material Inspection: Examine the quality of maize grain before milling, checking for moisture content, impurities, and overall grain health.

- Cleaning Processes: Utilize advanced cleaning techniques to eliminate foreign materials, ensuring that only the best grains proceed to milling.

- Milling Parameters Monitoring: Continuously check and adjust milling settings to align with established standards, optimizing particle size and texture.

- Quality Testing: Regularly conduct flour tests for consistency in protein content, granulation, and moisture levels to guarantee product excellence.

Moreover, creating a culture of quality awareness among staff contributes to better overall results. Deep engagement with employees ensures that they understand the importance of their roles in maintaining high industry standards. To facilitate this, companies can adopt structured training programs and performance monitoring. The following table outlines the essential training components:

| Training Component | Objective |

|---|---|

| Raw Material Quality Control | Understanding specifications for sourcing quality maize |

| Operational Best Practices | Enhancing skills for efficient milling operations |

| Health & Safety Standards | Ensuring safety measures during milling processes |

Exploring Market Opportunities and Trends in Maize Milling

The maize milling industry is witnessing a surge in demand, driven by various factors influencing market dynamics. Consumer preferences are shifting toward healthier, gluten-free alternatives, fostering the growth of maize-based products such as cornmeal and maize flour. Furthermore, advancements in milling technology are enhancing efficiency, thereby lowering operational costs and improving product quality. This transformation has opened exciting avenues for small to medium-sized enterprises (SMEs), urging them to innovate and expand their offerings in a competitive landscape. Key trends include the rise of organic and non-GMO maize products, which cater to health-conscious consumers and niche markets.

Additionally, the global trade of maize and maize products presents significant opportunities for exporters and importers. Emerging markets in Asia and Africa display a growing appetite for maize-based foods, driven by population growth and urbanization. An analysis of recent trade data reveals the following key insights:

| Region | Annual Growth Rate (%) | Potential Market Size (USD) |

|---|---|---|

| Africa | 5.2 | 2 billion |

| Asia | 7.1 | 3.5 billion |

| Latin America | 4.8 | 1.2 billion |

This data underscores the importance of targeted marketing and investment strategies in harnessing these opportunities. By focusing on quality, sustainability, and consumer education, businesses can leverage the changing tides of the market and secure their position in the maize milling sector.

Wrapping Up

As we conclude our exploration of maize milling, it’s clear that understanding the intricacies of this essential process is crucial for anyone looking to harness the potential of maize effectively. From selecting the right equipment to mastering the techniques that yield high-quality flour and meal, each aspect plays a pivotal role in the success of the milling operation.

With this comprehensive guide in hand, we hope you now possess the tools and knowledge necessary to embark on your maize milling journey. Whether you’re an aspiring miller, an established producer seeking to refine your process, or simply a curious enthusiast, the world of maize milling offers a rich tapestry of opportunities waiting to be uncovered.

Embrace the art and science of milling, and let the golden kernels transform into something extraordinary. The path to unlocking the full potential of maize is wide open—step forward and make your mark in this dynamic field.