In the intricate tapestry of agricultural production, few elements hold as pivotal a role as the rice mill—a hidden gem often overshadowed by the sprawling fields of golden grains. Acting as the heartbeat of grain processing, the rice mill transforms humble paddy into the versatile staple that graces tables around the world. This article embarks on a journey through the inner workings of these essential facilities, unveiling not just the engineering marvels and technological advancements that define modern rice milling, but also the cultural significance and economic impact woven into the very fabric of communities dependent on this vital process. Join us as we delve into the heart of grain processing, exploring how rice mills embody both tradition and innovation in their quest to nourish the global populace.

Exploring the Essential Machinery of Rice Milling

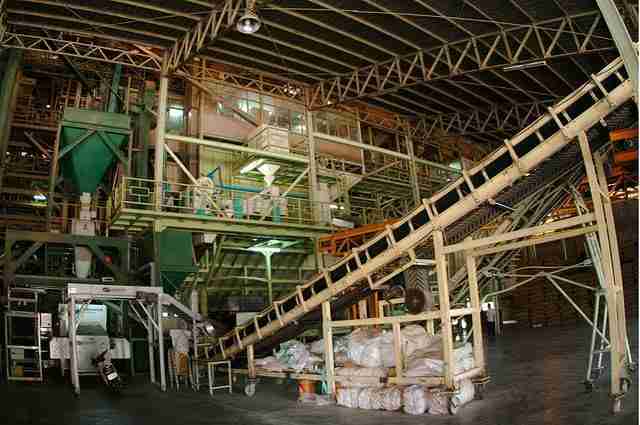

At the core of rice milling lies an intricate system of machinery that works harmoniously to transform raw grains into polished rice. Each component plays a pivotal role in ensuring the quality and efficiency of the milling process. The journey begins with the dehusking unit, where rough rice is stripped of its outer husk. Following this, the paddy separator comes into play, skillfully distinguishing between milled rice and unhulled paddy. This is crucial in optimizing the yield and minimizing waste, highlighting the importance of precision in grain processing.

Further along the assembly line, the rice undergoes multiple stages, each executed by specialized machinery designed for specific tasks. Key components of this process include:

- Milling machine: Buffs the brown rice to remove the bran layer.

- Whitener: Polishes the rice, enhancing its aesthetic appeal.

- Grader: Sorts the rice based on size and quality, ensuring uniformity.

- Packager: Prepares the final product for distribution, sealing in freshness.

A well-coordinated rice milling operation relies on these machines working in unison, where even minor deviations can impact the quality and quantity of the final product. Below is a simplified table summarizing the main stages of rice milling:

| Stage | Description |

|---|---|

| Dehusking | Removes the outer husk from the grains. |

| Milling | Removes the bran layer and polishes the rice. |

| Grading | Sorts rice based on size and quality. |

| Packaging | Prepares the final product for market. |

Understanding the Processing Journey from Grain to Table

The journey of rice from its natural state to the dining table is a fascinating and intricate process that highlights the artistry of grain processing. At the core of this transformation is the rice mill, where raw paddy undergoes a series of meticulous steps to ensure it reaches consumers in its finest form. The processing begins with the cleaning phase, where impurities and stones are removed, followed by dehusking, which separates the edible grain from its tough outer shell. From there, the rice is polished to achieve the desired texture and finish, enhancing both its aesthetic appeal and culinary qualities.

Each stage of grain processing plays a pivotal role in determining the quality and flavor of the final product. After polishing, rice can be sorted based on its size and quality, often utilizing advanced machinery to ensure uniformity. The table below outlines the essential steps in the processing journey along with their significant impacts on the rice quality:

| Processing Step | Description | Impact on Quality |

|---|---|---|

| Cleaning | Removal of impurities and foreign materials. | Ensures purity and safety for consumption. |

| Dehusking | Separation of the hull from the paddy grain. | Enhances edibility by making the grain accessible. |

| Polishing | Removal of bran layers for a smoother surface. | Improves texture and appearance, leading to better marketability. |

| Sorting | Classification by size and quality. | Increases consistency, ensuring customers receive high-quality products. |

Ultimately, the heart of rice processing lies in the meticulous attention given to each step, ensuring that every grain reaches the table in optimal condition. The skilled professionals at the rice mill work tirelessly to refine and perfect this process, embodying a tradition that blends agricultural practices with modern technology.

Optimizing Rice Quality: Best Practices in Milling Techniques

To achieve superior rice quality, the milling process is crucial. Advanced milling techniques not only enhance the appearance of the grains but also improve their nutritional value and cooking performance. Among the most effective practices is ensuring that the moisture content of the paddy is optimized before milling. This step prevents breakage and enhances the milling yield. Additionally, employing the right combination of tempering and polishing techniques can significantly influence the final product’s quality. Proper tempering helps to soften the outer layers of the grain, making it easier to remove during the milling process, while polishing enhances the rice’s luster and reduces bran particles.

Furthermore, the selection of machinery and equipment plays a critical role in rice milling optimization. Utilizing modern, high-efficiency mills with adjustable settings allows for customization based on the rice variety being processed. This flexibility is vital for achieving consistent grain quality. Key elements to focus on include the use of dehusking machines with optimal speed settings and smooth rollers, which minimize kernel damage. Regular maintenance and calibration of milling machines are also essential to preventing operational inefficiencies and ensuring that the equipment consistently delivers high-quality output. Implementing these best practices not only boosts the finished product’s market value but also satisfies consumer demand for premium rice.

| Aspect | Best Practice |

|---|---|

| Moisture Content | Optimal levels for reduced breakage |

| Tempering | Softens grains for easier milling |

| Polishing | Enhances luster and reduces bran |

| Equipment | Modern mills with adjustable settings |

| Maintenance | Regular calibration for efficiency |

Sustainable Practices for Modern Rice Processing Facilities

Modern rice processing facilities now hold the potential to significantly reduce their environmental footprint through the adoption of innovative and sustainable practices. By integrating energy-efficient machinery and renewable energy sources, these facilities can minimize resource consumption while maximizing output. The implementation of solar panels and biomass energy systems not only aids in reducing reliance on fossil fuels but can also alleviate operational costs over time. Additionally, water conservation techniques, such as recycling wastewater for cleaning processes or irrigation, contribute to sustainable water management that is essential in rice cultivation.

Moreover, the focus on waste management strategies plays a crucial role in enhancing sustainability within these facilities. By converting waste byproducts into valuable resources, rice mills can engage in circular economy practices that promote resourcefulness. For instance, rice husks can be repurposed as biofuel or utilized in the production of organic fertilizers. Other measures include the rigorous separation of waste materials and the use of green packaging solutions to reduce plastic usage. Below is a table summarizing some effective sustainable practices for rice processing:

| Practice | Description |

|---|---|

| Energy Efficiency | Using high-efficiency equipment to reduce energy consumption. |

| Water Conservation | Implementing systems to recycle and reuse water within the processing cycle. |

| Waste Repurposing | Converting byproducts into usable materials, like biofuels and fertilizers. |

| Eco-Friendly Packaging | Utilizing recyclable or compostable packaging materials to minimize waste. |

In Summary

As we conclude our exploration of the rice mill, the unsung hero of grain processing, it’s clear that this intricate system goes beyond mere machinery; it embodies the dedication of countless individuals who contribute to the food supply chain. The rhythmic sound of huskers and polishers, the scent of freshly milled rice—these elements are not just a backdrop but integral to the narrative of food production. In unveiling the rice mill, we have also unveiled a vital piece of agricultural artistry, a blend of tradition and technology that nourishes populations and sustains livelihoods. As we continue to seek innovation in grain processing, may we also honor the age-old practices that have shaped our relationship with this staple crop. In doing so, we affirm our commitment to sustainability, quality, and the rich legacy of our agricultural heritage, securing a future where food is not just produced, but celebrated.