Transforming Grains: An Insight into Industrial Rice Milling

In the heart of bustling economies and agricultural landscapes, one humble grain stands as a testament to nourishment and industry: rice. This staple, cherished across cultures and continents, undergoes a remarkable transformation before reaching our plates. The journey from paddy fields to polished grains is a complex interplay of nature and technology, where industrial rice milling plays a pivotal role. This process not only enhances the grain’s quality and shelf life but also influences food security and market dynamics on a global scale. Join us as we delve into the intricate world of industrial rice milling, exploring its processes, innovations, and the vital impact it has on both agronomy and culinary traditions. From the meticulous handling of harvested paddy to the final stages of packaging, we uncover how grains are transformed in a modern context, revealing the unseen craftsmanship behind this essential food source.

Exploring the Rice Milling Process from Field to Table

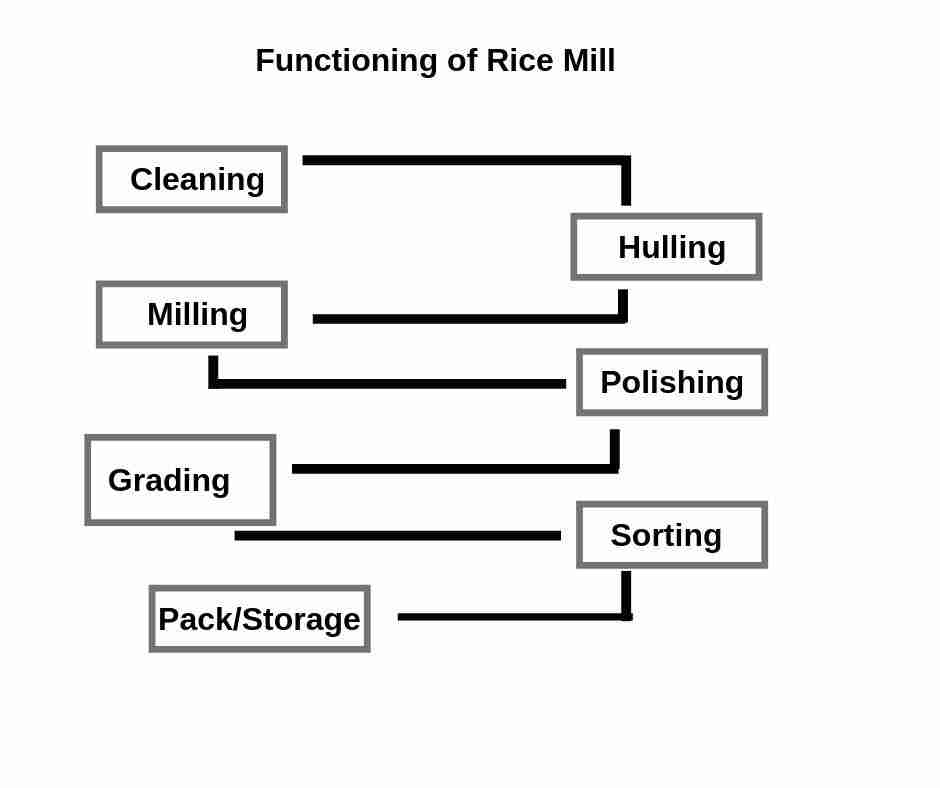

Rice milling is a fascinating journey that transforms harvested grains into the polished, white rice that graces tables around the world. The process begins in the vast, lush rice fields where farmers carefully cultivate and tend to the crops. Once the grains have reached maturity, they’re harvested and transported to milling facilities. There, the first step involves drying the grains to reduce moisture content, ensuring that they are preserved and ready for milling. Following this, the rice undergoes several stages, including cleaning to remove impurities, hulling to separate the outer husk, and polishing to achieve the glossy finish that is most familiar to consumers.

The transformation doesn’t stop there; additional processes enhance the rice’s quality and nutritional value. Milling facilities may also incorporate grading classifications, ensuring that the rice meets market standards. This is crucial not just for aesthetics but for the consistency of cooking results. To illustrate the different stages of rice milling and their impact on the final product, consider the following table:

| Stage | Description | Outcome |

|---|---|---|

| Harvesting | Gathering the matured rice grains from the fields | Freshly harvested rice |

| Drying | Reducing moisture content for preservation | Moisture-stable grains |

| Hulling | Removing the outer husk from grains | Brown rice |

| Polishing | Enhancing appearance and flavor | White rice |

Each step in this meticulous process plays a vital role in bringing the finest quality rice to consumers. By understanding the intricate operations behind industrial rice milling, we appreciate the labor, technology, and skill that contribute to this staple food’s journey from field to table. As rice continues to be a vital part of diets across cultures, the significance of these processes not only supports food security but also connects us to the rich agricultural heritage associated with this beloved grain.

Innovative Technologies Shaping the Future of Grain Transformation

The landscape of grain transformation is rapidly evolving, driven by cutting-edge technologies that enhance the efficiency and sustainability of industrial rice milling processes. Automated systems equipped with artificial intelligence and machine learning algorithms are increasingly employed to optimize milling operations. These technologies assist millers in analyzing data in real-time, ensuring optimal grain quality and minimizing waste. Moreover, the integration of robotics in handling and sorting grains allows for consistent and precise operations, reducing human error and increasing throughput.

In addition to automation, the advent of sustainable practices is reshaping how industries approach rice milling. Techniques such as cold milling and water recirculation systems not only preserve the nutritional quality of rice but also lower the energy consumption associated with traditional milling processes. Here’s a comparison demonstrating the impact of these innovations:

| Traditional Milling | Innovative Milling |

|---|---|

| Higher energy consumption | Reduced energy usage |

| Lower grain recovery rates | Enhanced recovery efficiency |

| Less attention to nutrition | Focus on nutritional retention |

| More waste produced | Minimized waste generation |

Through these revolutionary technologies, the future of rice milling looks promising, paving the way for a more efficient and environmentally friendly industry.

Best Practices for Enhancing Efficiency and Quality in Milling Operations

Enhancing efficiency and quality in milling operations involves a blend of cutting-edge technology, skilled workforce, and meticulous processes. To streamline the workflow, consider implementing automated systems that monitor grain flow and optimize parameters in real-time. This transition can significantly reduce waste and ensure consistent output quality. Additionally, investing in advanced milling machinery that incorporates variable speed motors can adaptively respond to different grain types, improving processing rates and minimizing damage to the kernels. Regular training sessions for team members on the latest best practices in milling technology can enhance operational knowledge and bolster productivity.

Furthermore, maintaining high standards of cleanliness and equipment upkeep is crucial in preserving both efficiency and grain quality. Establishing a routine maintenance schedule helps prevent unexpected breakdowns and prolongs machinery life. Implement safer handling practices and ensure thorough cleaning systems are in place to reduce cross-contamination. Implementing software solutions for data tracking can aid in identifying trends and inefficiencies, making it easier to pinpoint areas for improvement. Conducting regular quality audits and seeking feedback from operators can also foster a culture of continuous improvement, ensuring a sustainable and effective milling operation.

| Practice | Benefit |

|---|---|

| Automated Systems | Optimizes grain flow and reduces waste |

| Regular Training | Enhances team knowledge and productivity |

| Scheduled Maintenance | Prevents breakdowns and extends equipment life |

| Data Tracking | Identifies inefficiencies and trends |

| Quality Audits | Supports continuous improvement |

Sustainability in Rice Milling: Strategies for a Greener Industry

In the quest for environmental stewardship, rice milling industries are increasingly adopting innovative approaches that prioritize sustainability without compromising efficiency. By implementing energy-efficient technologies, mills can significantly reduce their carbon footprint while enhancing productivity. Sustainable practices include utilizing renewable energy sources such as solar panels and bioenergy derived from rice husks, which not only power operations but also minimize waste. Furthermore, water conservation techniques—like recirculating water systems—cut down on freshwater usage, addressing critical resource scarcity in many rice-producing regions.

Beyond energy and water management, there’s a growing emphasis on waste reduction and resource recovery within the milling process. Many mills are now exploring opportunities to repurpose by-products, such as rice bran and husk, into high-value products. Commonly adopted strategies include:

- By-product extraction: Utilizing rice bran for oil and nutritional supplements.

- Animal feed production: Converting husks into feed materials, adding value while minimizing landfill waste.

- Organic fertilizers: Basing soil amendments on rice straw, promoting a closed-loop system.

This shift not only supports local economies but also fosters a circular economy that benefits the environment in the long run.

To Wrap It Up

As we conclude our exploration of industrial rice milling, it becomes clear that this intricate process is more than just a means of transforming grains; it is a vital cog in the wheel of global food systems. The journey from paddy to polished rice involves a careful balance of technology, tradition, and sustainability, each influencing the final product that nurtures millions around the world.

Understanding the nuances of milling not only enriches our appreciation for this staple food but also highlights the significance of innovation in optimizing efficiency and reducing waste. By embracing new advancements while respecting the roots of rice cultivation, we pave the way for a more resilient agricultural future.

As consumers, we are invited to engage with the story behind our meals, recognizing the labor and ingenuity that make every grain count. In a world where the demand for food security and sustainable practices is more pressing than ever, the insights gained from industrial rice milling could illuminate paths toward a more equitable and mindful approach to our global food supply. Let us continue to support and celebrate the journey of grains—one that impacts not only our plates but also the broader tapestry of our economies and cultures.