As the sun peeks over the horizon, casting a golden glow across expansive fields of swaying rice plants, the world awakens to the symphony of agricultural productivity. At the heart of this cycle lies an often-overlooked marvel of modern engineering: the rice mill plant. In an era where food security and sustainability have become paramount, these facilities are not just processing hubs; they are the key players in a revolution aimed at enhancing harvesting efficiency. This article delves into the innovations and technologies transforming traditional rice milling practices, spotlighting the intricate processes, cutting-edge machinery, and the forward-thinking strategies that are setting new benchmarks in the industry. Join us as we explore how the rice mill plant is evolving to meet the demands of a growing global population while preserving the rich heritage embedded in its grains.

Optimizing Operational Practices for Enhanced Rice Milling Productivity

In the quest for improved productivity within rice milling operations, a systematic approach to refining practices can yield significant results. Implementing advanced technologies and automated systems not only enhances workflow but also reduces human error. Adopting real-time monitoring solutions allows for quick adjustments and analysis, while data-driven decision-making can streamline overall processes. Moreover, continuous training of staff in these technologies ensures that the workforce remains adept and ready to tackle challenges.

Moreover, optimizing the layout and design of the milling plant plays a pivotal role in enhancing efficiency. A clear and organized workflow minimizes bottlenecks, while adequate space for machinery and personnel contributes to a smoother operation. Consider the following elements to maximize productivity:

- Preventive Maintenance: Regular servicing of equipment can significantly reduce downtime.

- Inventory Management: Keeping optimal stock levels ensures that operations run without interruptions.

- Waste Minimization: Implementing strategies to reduce waste can improve overall yield and profitability.

| Improvement Area | Expected Outcome |

|---|---|

| Automation | Increased speed and quality of milling |

| Staff Training | Higher operational efficiency |

| Layout Optimization | Smoother workflow and reduced handling time |

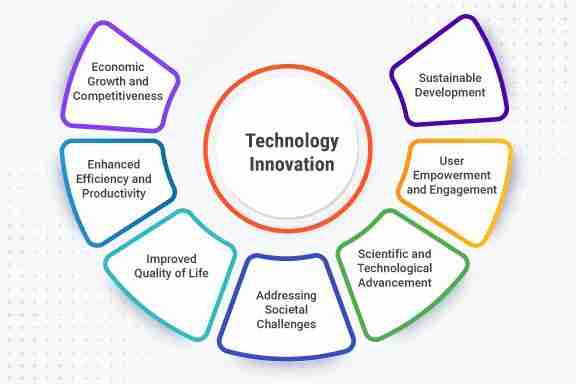

Innovative Technologies Redefining Quality and Consistency in Rice Processing

The evolution of rice processing technology has introduced groundbreaking advancements that ensure both quality and consistency in every grain. Automated systems, for instance, utilize precise algorithms to monitor moisture content, detect impurities, and adjust milling parameters in real-time. This not only minimizes human error but also enhances the overall efficiency of the production process. Important features of these innovative technologies include:

- Advanced Sorting Machines: Equipped with AI-driven vision systems that identify and separate defective grains with unparalleled accuracy.

- Smart Drying Equipment: Utilizes data analytics to optimize drying conditions, ensuring uniform moisture levels across batches.

- Integrated Quality Control: Continuous monitoring of temperature and humidity, allowing processors to maintain high-quality standards throughout the milling process.

Further, the integration of Internet of Things (IoT) technologies has bolstered traceability and transparency in the rice supply chain. By employing smart sensors, mills can collect real-time data on each processing stage, from harvesting to packaging. This allows for actionable insights that improve operational efficiency and product quality. Here’s a brief overview of the key IoT applications in rice processing:

| Application | Description |

|---|---|

| Remote Monitoring | Real-time tracking of machinery performance and system health. |

| Data Analytics | Analysis of processing data to prevent potential quality issues. |

| Supply Chain Optimization | Enhanced logistics through better inventory management and distribution forecasting. |

Sustainable Strategies for Waste Management and Resource Conservation

In the quest for resource conservation, modern rice mills are adopting innovative approaches that align with sustainable waste management practices. By integrating advanced machinery with eco-friendly techniques, these facilities are able to significantly reduce their environmental footprint. Some key methods embraced include:

- Zero-Waste Initiatives: Utilizing by-products such as husks and bran for energy generation and animal feed.

- Water Recycling Systems: Implementing closed-loop systems that minimize water wastage during milling.

- Energy Efficiency Programs: Investing in solar panels and energy-efficient motors to cut down on electricity consumption.

Furthermore, the commitment to sustainability extends beyond operational efficiency; it is also about fostering a culture of environmental stewardship. Most rice mills are now engaging in community outreach to educate farmers on sustainable practices, leading to an overall improvement in agricultural techniques. This proactive approach is characterized by:

- Collaborative Workshops: Hosting sessions that focus on eco-friendly farming techniques and post-harvest management.

- Research Partnerships: Collaborating with universities to develop innovative technologies that enhance resource conservation.

- Feedback Mechanisms: Establishing channels for farmers to voice concerns regarding sustainability and to share success stories.

| Key Initiative | Impact |

|---|---|

| Zero-Waste Initiatives | Reduces waste and generates additional revenue. |

| Water Recycling Systems | Conserves water and lowers operational costs. |

| Energy Efficiency Programs | Decreases carbon footprint and operational expenses. |

Training and Skill Development: Empowering the Workforce in Modern Rice Mills

The evolution of rice milling technology has led to significant transformations in the workforce’s skill set, making training and development paramount in today’s rice mills. As automation and modern machinery become the norm, it’s crucial for employees to acquire a comprehensive understanding of these advanced systems. Training programs are being tailored to include:

- Machine Operation: Hands-on training on the latest milling equipment ensures operators are proficient in managing high-tech machines.

- Quality Control: Educating staff on testing methods and quality metrics enables them to maintain the highest standards in rice production.

- Safety Protocols: Emphasizing workplace safety and emergency procedures creates a secure working environment for all employees.

Moreover, ongoing skill development initiatives foster a culture of continuous improvement among the workforce. This proactive approach not only enhances individual capabilities but also boosts overall productivity levels within the facility. Companies are now implementing:

- Workshops and Seminars: Regular sessions held by industry experts keep the team updated on the latest trends and innovations.

- Mentorship Programs: Pairing seasoned workers with newcomers facilitates knowledge transfer and strengthens team dynamics.

- Certification Courses: Offering recognized certifications can motivate employees and enhance their professional profiles.

Investment in these areas ultimately leads to a more agile and skilled workforce, driving efficiency across the plant. With the right training and development strategies in place, rice mills can truly revolutionize their operations, ensuring they remain competitive in a rapidly evolving industry landscape.

In Conclusion

As we draw our exploration of the revolutionized rice mill plant to a close, it becomes clear that the journey towards enhanced harvesting efficiency is a testament to innovation and dedication within the agricultural sector. The evolution of these facilities — from traditional methods to cutting-edge technology — illustrates not only a shift in productivity but also a commitment to sustainability, food security, and the resilience of farming communities worldwide.

As rice remains a staple for billions, the advancements in milling processes will continue to resonate through global markets and households alike. The stories of farmers, engineers, and technicians intertwine, illuminating a shared goal: to optimize every grain harvested.

As we look toward the future, it is essential to acknowledge the role of ongoing research and collaboration in sustaining this momentum. The rice mill plant revolution is not merely a chapter in agricultural history; it is an evolving narrative that invites us to reconsider how we approach food production in the face of changing climates and growing populations. May this journey inspire further exploration, innovation, and, ultimately, a bountiful future for all.