Unlocking the Secrets of Maize Milling: A Complete Guide

In the heart of countless culinary traditions across the globe, maize stands tall as a staple ingredient, transforming simple grains into a myriad of delightful dishes. Yet, the journey from ear to table is one marked by a fascinating and intricate process—milling. For many, the term “maize milling” is merely a technical aspect of food production, but it holds a wealth of secrets waiting to be uncovered. In this complete guide, we invite you to delve into the world of maize milling, where ancient methods meet modern innovations, and where the art of grinding corn reveals a rich tapestry of culture, nutrition, and sustainability. Whether you’re a culinary enthusiast, a food industry professional, or simply curious about the transformation of this versatile grain, join us as we unlock the secrets of maize milling—one kernel at a time.

Understanding the Maize Milling Process and Its Importance

The maize milling process is a multifaceted operation that transforms whole maize kernels into various forms of flour, meal, and byproducts. This essential procedure not only harnesses the nutritional benefits of maize but also supports food security and diverse culinary applications. The milling process begins with cleaning, which removes impurities such as dust, stones, and foreign seeds. Following this, the maize undergoes wetting to facilitate smoother milling, where precision plays a crucial role in achieving the desired texture. The next phase is grinding, where the maize is crushed between rollers or stones into flour. This flour can vary in fineness, catering to different uses in baking, cooking, or other food production.

Understanding the milling process is vital for both producers and consumers, as it directly influences the quality and nutritional value of the final product. The various grades of maize flour, which can vary from fine to coarse, allow for a broad spectrum of culinary applications. Key benefits of comprehending this process include:

- Informed Choices: Consumers can select products that suit their dietary needs and preferences.

- Quality Control: Producers can ensure they maintain high standards in their milling operations, leading to better end products.

- Resource Optimization: Recognizing byproducts can lead to more effective use of maize, minimizing waste and enhancing sustainability.

the maize milling process is more than just a production line; it is a critical factor in food systems worldwide. As the demand for various maize products continues to grow, understanding each step of this process empowers stakeholders to innovate and improve efficiency, ensuring the best quality food for consumers everywhere.

Choosing the Right Equipment for Efficient Milling

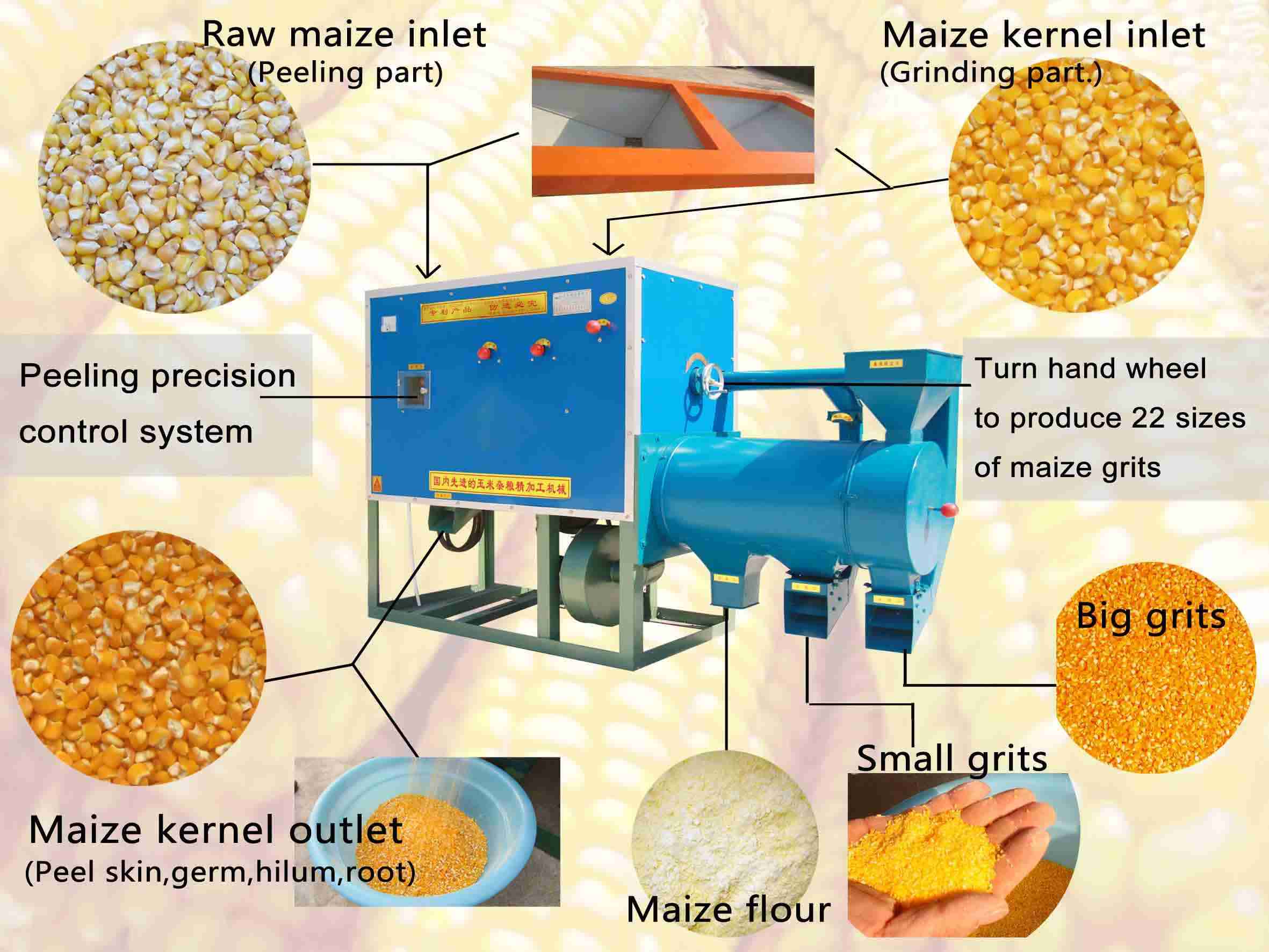

In the world of maize milling, selecting the right equipment is crucial for achieving optimal efficiency and product quality. The process typically involves several stages, each of which requires specific machinery that must work in harmony. From the initial cleaning of maize to the final milling process, investing in reliable equipment can significantly impact your operational productivity. Essential machinery includes:

- Maize Cleaners – These machines remove impurities and ensure only the best kernels proceed to milling.

- Degerminator – This equipment efficiently removes the germ and hull from the maize, enhancing shelf life and taste.

- Milling Machines – Whether using hammer mills or roller mills, the choice depends on desired flour texture and end product specifications.

- Sifters – To separate different flour grades and maintain consistency in the final product.

Choosing the appropriate equipment goes beyond just functionality; it also involves considering factors like energy efficiency, ease of maintenance, and support services. A well-integrated milling system not only minimizes waste but also maximizes output, making the entire operation more cost-effective. To guide your choices, the following table highlights high-performance attributes of popular milling equipment:

| Equipment Type | Key Features | Benefits |

|---|---|---|

| Maize Cleaners | High Efficiency, Low Maintenance | Enhances product quality and reduces contaminants |

| Degerminator | Precision Cutting, Adjustable Settings | Improves flavor and extends shelf life of flour |

| Milling Machines | Versatile, High-Throughput | Produces various flour textures for diverse product needs |

| Sifters | Multi-Dimensional Screening | Ensures product uniformity and grade separation |

Quality Control Measures for Superior Maize Flour

Ensuring the highest quality of maize flour is a meticulous process that involves a variety of quality control measures. These practices not only enhance the product’s safety and taste but also maintain its nutritional value. Key steps include:

- Raw Material Inspection: Thorough examination of maize kernels for moisture content, impurities, and kernel integrity.

- Laboratory Testing: Regular analysis for contaminants such as aflatoxins, mycotoxins, and other pathogens.

- Grinding Process Monitoring: Maintaining optimal grinding temperatures to avoid denaturing essential nutrients.

- End Product Testing: Frequent sampling of flour to ensure consistency in texture, color, and flavor.

In addition to these proactive measures, it’s crucial to implement a robust traceability system throughout the milling process. This includes:

| Traceability Aspect | Description |

|---|---|

| Supplier Verification | Confirming the reliability and compliance of maize suppliers. |

| Batch Tracking | Identifying specific batches of grain used in each production cycle. |

| Document Control | Maintaining records on milling parameters and quality test results. |

Innovative Techniques to Enhance Maize Milling Operations

Incorporating cutting-edge technology into maize milling operations not only enhances efficiency but also maximizes product quality. One innovative technique gaining traction is the use of smart sensors throughout the milling process. These sensors can monitor temperature, moisture content, and particle size in real time, allowing mill operators to make quick adjustments. Additionally, the integration of automation systems reduces human error and increases throughput, enabling a more consistent product. Some mills are also exploring the potential of artificial intelligence to analyze milling patterns and optimize machinery performance based on historical data.

Furthermore, sustainable practices are becoming crucial in modern maize milling. A shift towards energy-efficient machinery can significantly reduce operational costs while minimizing the carbon footprint. Mills are now adopting by-product utilization systems that not only enhance profitability but also reduce waste. For instance, milling by-products such as bran can be repurposed for animal feed or even biofuel production. The following table outlines some of these innovative techniques and their benefits:

| Technique | Benefits |

|---|---|

| Smart Sensors | Real-time monitoring, quick adjustments |

| Automation Systems | Reduced human error, increased throughput |

| AI Optimization | Data-driven performance enhancements |

| Energy-efficient Machinery | Lower operational costs, reduced emissions |

| By-product Utilization | Enhanced profitability, waste reduction |

In Retrospect

As we draw the curtain on our exploration of maize milling, we hope this guide has illuminated the intricate processes and nuances that make this age-old craft both vital and fascinating. From the first kernels of corn to the finely milled flour that graces our tables, the journey of maize is a testament to innovation and tradition.

Remember, whether you are a seasoned miller or a curious newcomer, embracing the secrets of maize milling opens up a world of culinary possibilities. As you step into the realm of grains, let curiosity be your compass and creativity your guide. With every batch you mill, you contribute to a legacy that transcends time and borders, transforming humble maize into a cornerstone of nourishment and culture.

So, gather your tools, sharpen your skills, and dive into the art of milling with confidence. The grains await, and the secrets are yours to unlock. Happy milling!