Transforming Grain: The Art and Science of Cereal Processing

In a world where the humble grain often takes a backseat to more glamorous ingredients, the journey from field to table remains a fascinating interplay of age-old traditions and modern innovations. Grain, the backbone of many diets worldwide, undergoes a remarkable transformation that is both an art and a science, reflecting the delicate balance between nature’s bounty and human ingenuity. From the golden fields of wheat swaying in the breeze to the flaked breakfast cereals densely packed in colorful boxes, the process of cereal manufacturing encompasses a range of techniques and technologies that elevate simple staples into essential components of our everyday lives. This article delves into the intricate world of cereal processing, exploring the meticulous methods that breathe life into grains, the nutritional considerations that shape our choices, and the relentless pursuit of innovation that continues to redefine how we experience the foods we consume. Join us as we uncover the secrets behind this transformative journey and celebrate the complex relationship between grain and the myriad ways it sustains and nourishes our global community.

Understanding the Journey from Field to Flour: A Comprehensive Overview of Cereal Processing

Every grain begins its journey from the field, where it is carefully harvested at the peak of its ripeness. Once gathered, it enters the processing facility, where a meticulous series of steps transforms it into flour. The first stage involves cleaning, where grains are purified from impurities such as stones, dirt, and dust. Following this, the grains are subjected to conditioning, a process that adjusts moisture levels to prepare them for milling. The next step, grinding, breaks the grains down into smaller particles, ultimately turning them into flour. This phase is essential as the fineness of the flour affects the texture and quality of the final product. After milling, various enhancements may be applied, including the addition of nutrients to fortify the flour.

As the flour exits the mill, it undergoes several quality checks to ensure it meets industry standards, which include analyzing its protein content, gluten strength, and color. These factors are crucial as they dictate how the flour will behave in baking applications. Understanding these attributes unlocks the potential for creating different types of baked goods, whether it be artisan breads or delicate pastries. To illustrate this, consider the following table which compares the key attributes of different types of flour:

| Type of Flour | Protein Content | Best Uses |

|---|---|---|

| All-Purpose Flour | 10-12% | Breads, Cookies, Cakes |

| Whole Wheat Flour | 13-15% | Whole Grain Breads |

| Pastry Flour | 8-10% | Pies, Tarts |

The Role of Technology in Enhancing Grain Quality: Innovations in Processing Techniques

The intersection of technology and agriculture has forged a path toward unprecedented advancements in grain processing. Innovative wet and dry milling techniques, coupled with precision engineering, have transformed how grains are processed, ensuring superior quality and consistency. Through state-of-the-art machinery, processors can now achieve optimal extraction rates while minimizing waste, which reflects a growing commitment to sustainability in the grain industry. Notable technologies include:

- Ultrasonic Processing: Enhances moisture retention and uniformity.

- Laser Sorting: Improves grain selection by eliminating impurities.

- Advanced Drying Systems: Ensures optimal preservation of nutritional value.

Moreover, the application of data analytics and AI in monitoring grain quality represents a paradigm shift in cereal processing. By employing real-time data tracking, processors can predict potential quality fluctuations and promptly adjust parameters to maintain peak standards. Integrating IoT devices allows for seamless communication between machinery and monitoring systems, resulting in better operational efficiencies. The following table highlights some key technology applications shaping the future of grain processing:

| Technology | Benefit | Impact |

|---|---|---|

| Blockchain | Traceability | Enhances consumer trust |

| Big Data Analytics | Optimization | Improved yield and quality |

| Robotic Automation | Efficiency | Reduces labor costs |

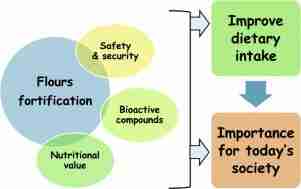

Nutritional Fortification: Balancing Flavor and Health in Cereal Production

In the evolving landscape of cereal production, nutritional fortification plays a pivotal role in enhancing the health benefits of breakfast favorites. It involves the incorporation of essential vitamins, minerals, and other nutrients into grain-based products, ensuring that each bowl of cereal provides substantial dietary advantages. This balancing act between flavor and nutrition necessitates careful ingredient selection, as manufacturers seek to maintain the appealing taste and texture consumers expect while boosting health benefits. Key elements to consider include:

- Vitamin D and Calcium: Often added to support bone health.

- Iron and Folic Acid: Essential for energy levels and overall well-being.

- Fiber: Included to aid digestion and enhance satiety.

The challenge lies in achieving the right harmony between enhanced nutritional value and consumer palatability. Advances in food science allow for innovative approaches to fortification, such as microencapsulation techniques that mask the taste of added nutrients without compromising texture. This has led to a surge in products that not only promote health but also delight the senses. Consider the following examples of fortification strategies in different cereals:

| Cereal Type | Main Nutrient Added | Flavor Enhancement Method |

|---|---|---|

| Whole Grain Oats | Beta-glucans | Natural Vanilla Extract |

| Rice Cereal | B Vitamins | Cocoa Powder |

| Multi-Grain Flakes | Zinc and Iron | Honey and Cinnamon |

Through such advancements, cereal production not only meets the demand for nutritious options but also embraces the culinary artistry required to create enjoyable eating experiences. As the industry continues to innovate, balancing these two pillars will determine the future of cereal consumption, making each product a delightful possibility for health-conscious consumers.

Sustainability in Cereal Processing: Best Practices for Eco-Friendly Operations

In the quest for eco-friendly operations within cereal processing, implementing best practices is crucial for reducing the environmental footprint of grain transformation. This encompasses several key strategies that processors can employ to cultivate sustainability while still achieving high-quality outputs. Among these efforts, the following stand out:

- Energy Efficiency: Utilizing renewable energy sources, such as solar or wind, can significantly decrease reliance on fossil fuels, leading to reduced greenhouse gas emissions.

- Water Conservation: Implementing systems for recycling water within processing plants minimizes waste and promotes the responsible management of this vital resource.

- Waste Reduction: Adopting a zero-waste philosophy by reusing by-products or repurposing them for animal feed or bioenergy can enhance overall sustainability.

- Sustainable Sourcing: Partnering with local, organic farmers not only supports local economies but also reduces the carbon footprint associated with transporting raw materials.

Furthermore, implementing innovative technologies can propel eco-friendly cereal processing to new heights. For example, advanced milling techniques can optimize the extraction of valuable nutrients while minimizing losses. Additionally, investing in eco-conscious packaging helps to reduce plastic waste and encourages consumers to engage in sustainable practices. The following table illustrates some technological advancements impacting sustainability:

| Technology | Impact on Sustainability |

|---|---|

| Energy-efficient grinders | Lower energy consumption and emissions |

| Water recirculation systems | Significant reduction in water usage |

| Biodegradable packaging | Minimizes plastic landfill waste |

Key Takeaways

As we conclude our exploration of “Transforming Grain: The Art and Science of Cereal Processing,” we stand at the intersection of tradition and innovation. The transformation of grain is not merely a mechanical process; it is a delicate ballet of nature and human ingenuity that has evolved over millennia. From the humble wheat fields to the bustling silos, every kernel tells a story—a story of agriculture, technology, and culture.

In the microcosm of a processing facility, the alchemy of transformation unfolds. Through precise techniques and scientific understanding, grains are elevated into a plethora of products that nourish bodies and inspire culinary creativity. As we savor the array of breads, cereals, and snacks that grace our tables, we gain a deeper appreciation for the art and science behind their creation.

Ultimately, the process of transforming grain reflects our broader relationship with food—one that blends history, responsibility, and sustainability. As we look to the future, the challenge remains to honor this rich heritage while embracing innovations that ensure a more sustainable and equitable food system. In every bite, let us remember the journey from field to fork, and the remarkable people and processes that shape our daily sustenance. The art and science of cereal processing may be a backdrop in our daily lives, but it is a vital narrative that continues to unfold, one grain at a time.