In the heart of bustling rice mills, a silent artisan works diligently, transforming unrefined grains into the luminous staples that grace tables around the world. These unsung heroes of the food industry are the rice polishers, machines that craft perfection from nature’s bounty. As they gently buff and refine each grain, their essential role transcends mere aesthetics; they enhance flavor, improve texture, and extend shelf life. In this exploration of “Shining Grains: The Essential Role of Rice Polishers,” we delve into the intricate dance between technology and tradition, uncovering how these innovative machines not only preserve quality but also uphold the cultural significance of rice in cuisine. Join us as we journey through the process, discovering the impact of rice polishers on global food production and the culinary arts that enrich our lives.

Understanding Rice Polishers and Their Functionality

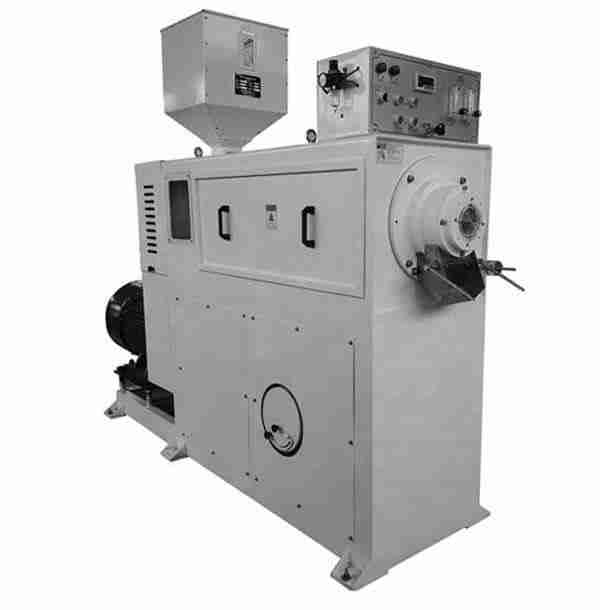

Rice polishers are remarkable machines designed to enhance the quality and appearance of rice. By utilizing a combination of friction and air flow, these devices effectively remove the outer husk and bran layers, resulting in polished grains that are more appealing to consumers. The functionality of rice polishers is rooted in their ability to balance aesthetic and nutritional needs. While excessive polishing may create beautifully shiny grains, it can also lead to significant nutrient loss, emphasizing the need for manufacturers to make informed choices regarding the level of polishing. To achieve the finest results, rice polishers often feature adjustable settings, allowing operators to control the degree of husk and bran removal tailored to specific market demands.

The operational efficiency of rice polishers is impacted by several factors, making them indispensable in modern milling processes. Key aspects of their functionality include:

- Uniformity: Ensures consistency in grain size and shape.

- Speed: Processes large quantities of rice quickly, increasing productivity.

- Energy Efficiency: Designed to consume less energy compared to traditional methods.

- Maintenance: Built for easy cleaning and upkeep, promoting longevity.

In addition, rice polishers often come with advanced features like automated monitoring systems, allowing operators to oversee performance metrics in real-time. This precision not only enhances quality control but also minimizes waste, ensuring that every grain is polished to perfection without compromising its inherent nutritional value. The delicate balance between aesthetics and nutrition makes rice polishers a vital component in the journey from field to table.

The Impact of Rice Polishers on Grain Quality and Nutrition

Rice polishers play a crucial role in enhancing the quality and nutritional value of grains, acting as the unsung heroes of the milling process. By effectively removing the outer husk and bran layers, these machines not only contribute to the aesthetic appeal of rice but also help in preserving its nutritional profile. Opting for a well-designed polisher ensures a delicate balance between removing impurities and maintaining essential nutrients. This process is vital, as the bran layer contains numerous vitamins, minerals, and antioxidants that are necessary for health.

The advantages of utilizing rice polishers extend beyond mere visual enhancement; they deeply influence the grain’s overall quality and digestibility. When polished properly, rice can achieve a smoother texture, allowing for better absorption of flavors during cooking. Moreover, polished grains are not just visually appealing; they also have a longer shelf life due to reduced moisture and spoilage. Some key benefits include:

- Improved Taste: Polished grains often showcase better flavor and aroma.

- Enhanced Cooking Qualities: Smoother surface helps cook evenly.

- Increased Nutritional Value: Helps retain more essential vitamins and minerals.

Choosing the Right Rice Polisher for Your Needs

When selecting a rice polisher, it’s essential to consider several key factors that align with your specific needs and culinary goals. First, evaluate the scale of your operation: are you a small family business, or do you operate on a larger commercial scale? This will significantly influence your choice of machinery. Additionally, think about the type of rice you commonly process, as different polishing methods may be more effective on certain varieties. Lastly, check for features such as adjustable polishing times, which allow you to customize the texture and appearance of your rice to suit various recipes and preferences.

Another crucial aspect is the efficiency and maintenance of the rice polisher. A machine’s energy consumption and ease of cleaning can impact both your operational costs and the quality of your final product. Consider models with durable materials designed for longevity, ensuring you get the best value for your investment. Below is a comparison table of some popular rice polishers that highlights their main attributes:

| Model | Capacity (kg/h) | Power (kW) | Features |

|---|---|---|---|

| PoliMax 3000 | 600 | 3.5 | Adjustable settings, energy-efficient |

| ShinePro 800 | 800 | 5.0 | High-speed polishing, stainless steel |

| RiceGlow S200 | 400 | 2.0 | Compact design, easy to clean |

Best Practices for Maintaining Rice Polishers for Optimal Performance

To ensure that your rice polishers operate at peak efficiency, regular maintenance is key. Routine cleaning is essential, as accumulated dust and residue can affect performance and the quality of the polished rice. It is important to check and clean the polishing chamber, belts, and rotating surfaces frequently. Lubrication is another critical aspect; applying the right lubricant to moving parts minimizes friction and prolongs the lifespan of your machine. Additionally, monitoring wear and tear on components like the polishing pads or sieves helps you to recognize potential issues before they escalate, ensuring your rice polisher continues to deliver high-quality output.

Moreover, keeping a meticulous maintenance schedule can greatly enhance the machine’s operational consistency. Here are a few recommended practices to consider:

- Daily Inspection: Check for any unusual noises or vibrations during operation.

- Weekly Cleaning: Remove and clean any accessible components to prevent buildup.

- Monthly Lubrication: Apply the appropriate lubricant to all moving parts.

- Quarterly Replacements: Change polishing pads and inspect electrical connections for damage.

For ease of reference, here’s a simple maintenance table:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Machine | Daily | Listen for noises; look for leaks. |

| Clean Polishing Chamber | Weekly | Ensure no rice residue is left behind. |

| Lubricate Moving Parts | Monthly | Use manufacturer-recommended lubricant. |

| Replace Worn Components | Quarterly | Inspect for signs of wear or damage. |

Final Thoughts

rice polishers stand at the intersection of tradition and technology, playing an indispensable role in the journey of rice from field to table. Their ability to enhance the quality and presentation of rice not only elevates culinary experiences but also supports the livelihoods of farmers and millers alike. As we reflect on the processes that transform humble grains into shining culinary gems, it becomes clear that rice polishers are more than mere machinery—they are vital partners in the story of sustenance and flavor. As we continue to explore the intricate relationships between food production and consumer expectations, let us appreciate the often-overlooked marvels of the milling industry, ensuring that the grains we cherish are polished to perfection.