Unlocking the Secrets of Cereal Processing: A Deep Dive

Cereal grains have nourished civilizations for thousands of years, serving as the cornerstone of diets around the globe. Yet, behind the familiar crunch of breakfast cereals and the warm embrace of freshly baked bread lies a complex tapestry of processes that transform raw grains into the products we love. From the fields where crops are harvested to the state-of-the-art facilities where grains undergo sophisticated processing, the journey of cereal is both art and science. In this article, we embark on a deep dive into the world of cereal processing, unveiling the intricate techniques and innovative technologies that contribute to everything from texture to flavor. Along the way, we’ll discover the impact of these processes on nutrition, sustainability, and consumer choices. Join us as we unlock the secrets of cereal processing, revealing the hidden wonders of one of our most beloved food staples.

Understanding Raw Ingredients and Their Impact on Cereal Quality

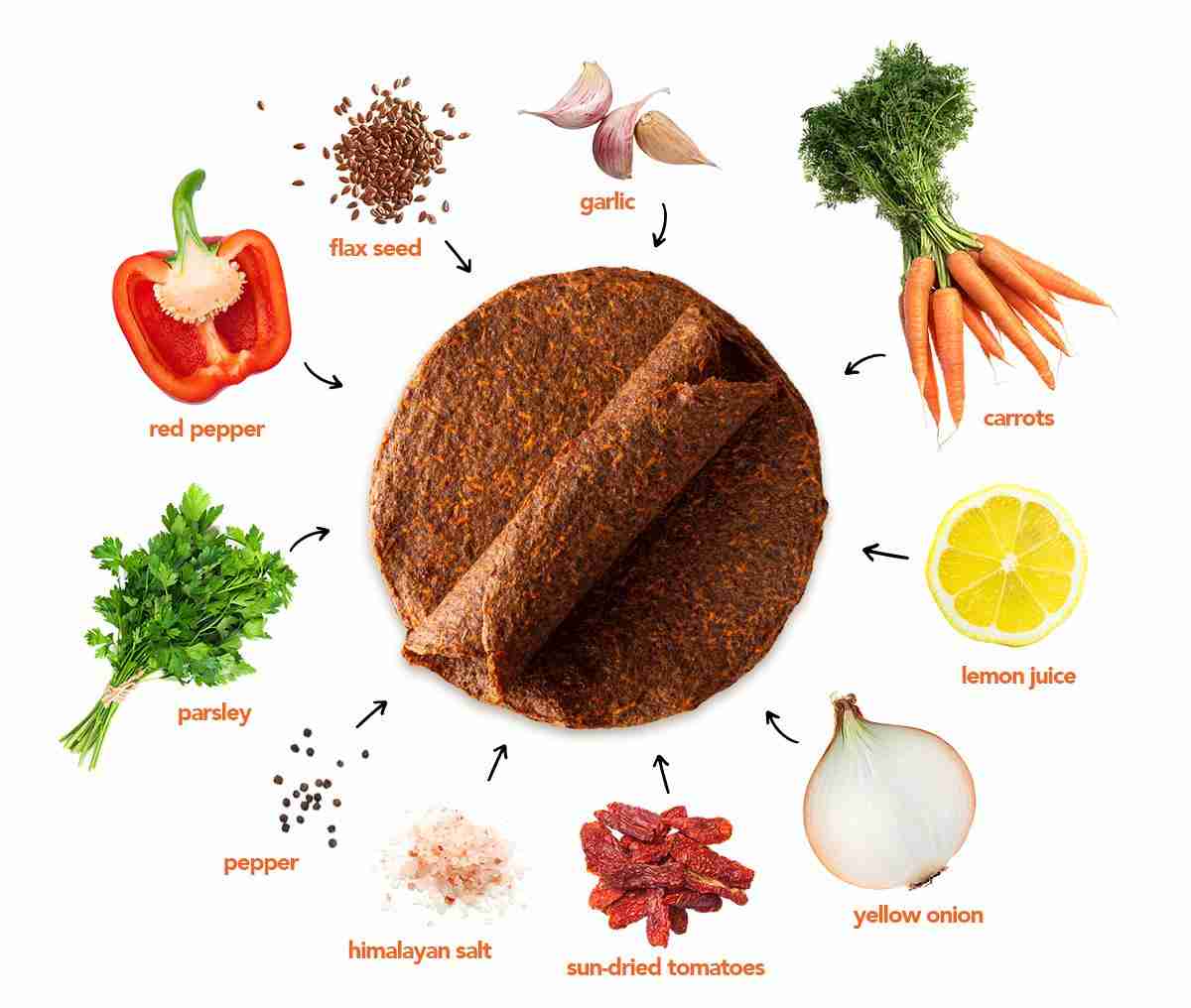

When it comes to producing high-quality cereals, the choice of raw ingredients plays a pivotal role in determining both flavor and nutritional value. Each ingredient—whether it be grains, sweeteners, or additives—contributes distinctive characteristics that can enhance or hinder the overall quality of the final product. Factors such as origin, variety, and processing methods significantly influence the attributes of these ingredients, leading to variations in texture, taste, and appearance. For instance, the type of wheat used can impact gluten formation, which is crucial for the texture of many cereal products.

In addition to selecting the right ingredients, understanding their interactions is equally vital. The chemical properties of ingredients can alter the cooking process and flavor profile, influencing consumer satisfaction. Various elements, including moisture content and pH levels, can determine how ingredients bind together during mixing and baking. Here are some key considerations to keep in mind:

- Quality of Grains: Fresh grains with high protein content yield better texture.

- Sweeteners: Natural sweeteners can enhance flavor without adding artificial taste.

- Fortification: Adding vitamins and minerals can improve nutritional value significantly.

To illustrate the impact of different ingredients on cereal quality, consider the following table showcasing various grains and their properties:

| Grain Type | Protein Content | Texture | Nutritional Benefits |

|---|---|---|---|

| Oats | 14g/100g | Chewy | High in fiber, heart-healthy |

| Wheat | 10g/100g | Fluffy | Rich in B vitamins |

| Rye | 13g/100g | Dense | Supports gut health |

Innovative Processing Techniques That Enhance Flavor and Texture

In the quest for optimal flavor and texture in cereals, manufacturers are constantly exploring innovative processing techniques that can bring out the best in their products. One such method is extrusion, a high-temperature, high-shear process that not only shapes the cereal but also transforms its physical and chemical properties. This technique helps maintain the nutrients while creating a light, crispy structure that enhances the overall mouthfeel. The variations in temperature and moisture content during the extrusion process can result in unique flavor profiles, making each bowl of cereal a distinct experience. Additionally, ingredients such as spices and natural flavors are often added during this phase, allowing for a more complex taste that excites the palate.

Another groundbreaking method involves the use of fermentation. Fermented cereals undergo microbial action that breaks down complex carbohydrates, resulting in a naturally sweeter taste and probiotics that contribute to gut health. The fermentation process can also improve the digestibility of the grains, enhancing texture and providing a satisfying chewiness. Moreover, in combinations with drying techniques like freeze-drying or air-drying, manufacturers can intensify flavors while preserving the nutrients. This synergy between fermentation and drying not only serves to create artisanal cereals but also taps into modern health trends, appealing to the conscious consumer. Here’s a simple comparison table showcasing these techniques:

| Technique | Benefits | Flavor Enhancement |

|---|---|---|

| Extrusion |

|

Complex profiles through added ingredients |

| Fermentation |

|

Rich, satisfying flavors |

Sustainability Practices in Cereal Production

Modern cereal production has increasingly embraced practices that prioritize ecological balance and resource efficiency. Farmers are now focusing on crop rotations and intercropping to enhance soil health and reduce dependency on chemical fertilizers. This sustainable approach not only boosts biodiversity on farms but also helps in the natural management of pests and diseases. Some key sustainability practices include:

- Reduced tillage: Minimizing soil disruption to conserve moisture and prevent erosion.

- Cover crops: Planting crops during off-seasons to protect soil and improve its structure.

- Irrigation efficiency: Implementing drip irrigation systems to optimize water usage.

Additionally, the commitment to sustainability extends to the entire supply chain, influencing processing methods and packaging options. Producers are increasingly adopting renewable energy sources, such as solar and wind, to power their operations. Sustainable packaging solutions, like biodegradable materials and reduced plastic use, are also gaining traction. Key strategies in this realm include:

| Strategy | Description |

|---|---|

| Solar energy | Using solar panels to reduce carbon footprint in production facilities. |

| Compostable packaging | Utilizing materials that can break down naturally to minimize waste impact. |

| Digital traceability | Leveraging technology to track sustainability metrics throughout the supply chain. |

Navigating Regulatory Standards in Cereal Manufacturing

In the intricate world of cereal manufacturing, understanding and adhering to regulatory standards is paramount. These regulations, established by government and industry bodies, ensure that cereals are produced safely and efficiently, without compromising the health of consumers. To navigate this complex landscape, manufacturers need to familiarize themselves with a myriad of guidelines that encompass everything from ingredient sourcing to labeling practices.

Key aspects of regulatory compliance include:

- Ingredient Integrity: All raw materials must meet specified quality and safety standards.

- Hygiene Protocols: Facilities must adhere to stringent sanitation practices to prevent contamination.

- Labeling Requirements: Accurate labeling is necessary to inform consumers about allergens and nutritional content.

To give a clearer picture of what these regulations may look like, consider the following table that outlines essential compliance areas:

| Compliance Area | Key Requirements |

|---|---|

| Ingredient Sourcing | Verify supplier certifications and traceability |

| Production Processes | Implement HACCP (Hazard Analysis Critical Control Point) |

| Quality Control | Regular testing of final products for safety and quality |

By proactively addressing these compliance areas, cereal manufacturers can not only ensure regulatory adherence but also enhance their brand reputation and build consumer trust. A comprehensive understanding of these standards also paves the way for innovation, allowing producers to explore new ingredients and production methods while remaining within the bounds of regulation.

The Way Forward

As we conclude our exploration into the intricate world of cereal processing, it’s evident that what might seem like a simple breakfast staple is, in fact, a product of remarkable engineering and artistry. From the meticulous selection of raw grains to the final packaging that graces our grocery store shelves, each step in the processing journey plays a vital role in shaping the nutrition, texture, and flavor we come to expect.

Understanding the complexities behind our favorite cereals not only deepens our appreciation for the food we consume but also highlights the importance of innovation and technology in meeting the demands of a growing population. As we continue to demand variety and convenience in our diets, the cereal industry must evolve, adapting to new health insights and sustainability practices.

So, the next time you pour a bowl of cereal, take a moment to ponder the myriad of processes that brought it to your table. In a world where food production often goes unnoticed, let this knowledge spark curiosity and inspire us all to engage with the foods we cherish. The secrets of cereal processing reveal not just the how, but also the why—making each bite a testament to human ingenuity.