In an era where food security and sustainable agriculture are at the forefront of global conversations, the significance of efficient grain processing cannot be overstated. For entrepreneurs and investors alike, the rice milling industry stands out as a beacon of opportunity, marrying economic viability with social impact. Amidst the rising demand for high-quality rice and the need for innovative processing solutions, launching a 2-ton rice mill plant emerges as a strategic investment worth considering. This article delves into the multifaceted dimensions of establishing a rice mill, exploring not only the technical aspects of the setup but also the economic implications that can drive community growth and personal success. Whether you’re a seasoned investor or a newcomer to the agribusiness landscape, understanding the intricacies of this venture could unlock doors to a prosperous future. Join us as we navigate the essential factors that make the establishment of a 2-ton rice mill plant a compelling addition to the agricultural investment portfolio.

Understanding the Market Demand for Rice Milling Operations

To effectively navigate the rice milling industry, it’s crucial to grasp the intricacies of market demand. The robust consumption of rice globally, driven by its status as a staple food in numerous regions, has spurred the establishment of milling operations. Factors influencing this demand include:

- Population Growth: An increasing global population and urbanization lead to higher rice consumption.

- Consumer Preferences: A growing trend for processed food is intensifying the need for quality rice products.

- International Trade: Export opportunities in rice-surplus countries are amplifying the demand for milling technology.

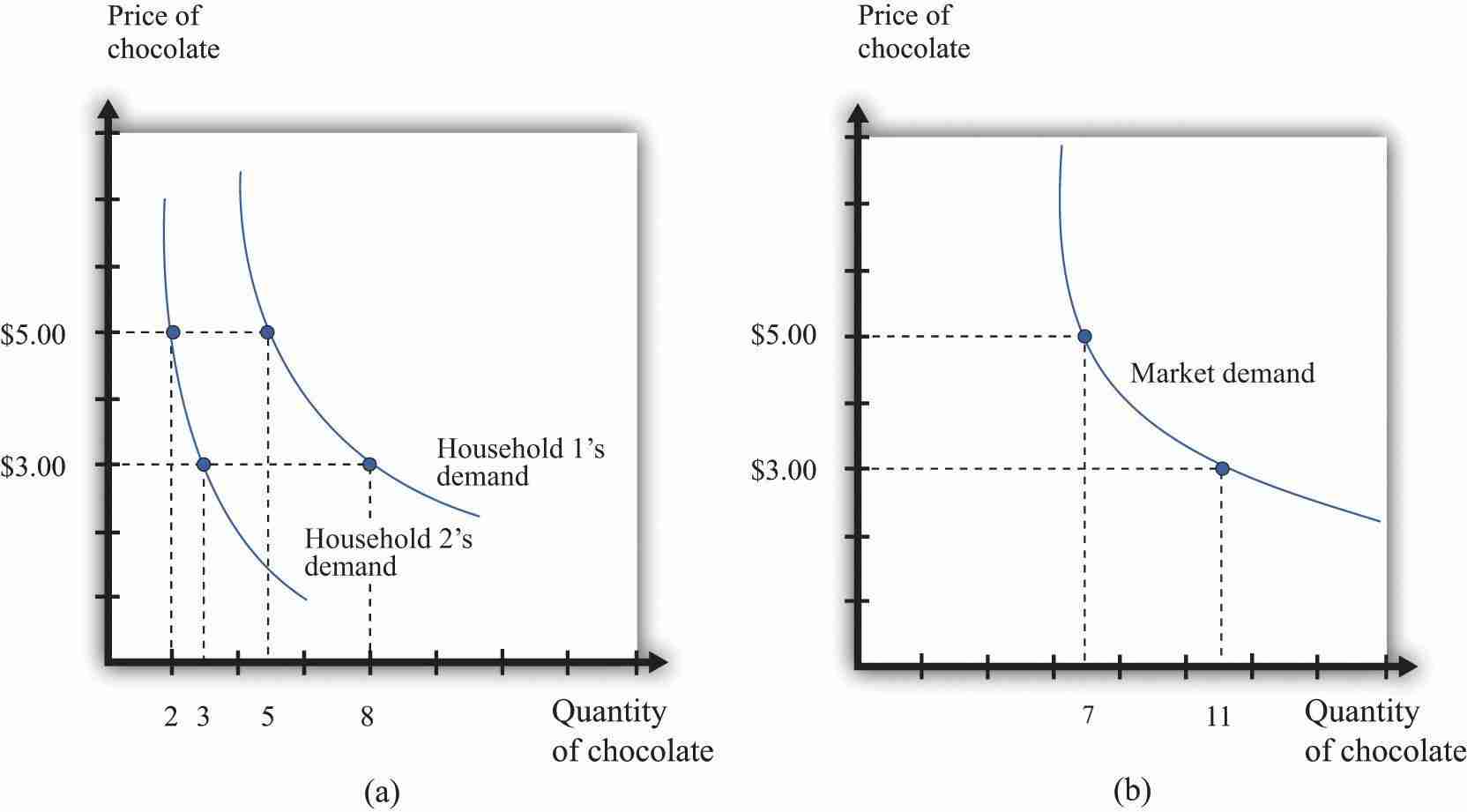

Moreover, understanding the geographic nuances of rice distribution can provide insights into the ideal locations for milling plants. For instance, regions with high paddy production can be optimal due to reduced transportation costs. A comparative analysis of these factors reveals key insights into potential profitability:

| Region | Paddy Production (tons) | Market Demand Index |

|---|---|---|

| Southeast Asia | 40 million | High |

| South Asia | 30 million | Very High |

| Africa | 10 million | Medium |

Evaluating the Key Components of a Successful Rice Mill Plant

When embarking on the journey of establishing a rice mill plant, several key elements must be meticulously assessed to ensure long-term success and efficiency. Location plays a crucial role, as proximity to rice fields reduces transportation costs and preserves grain quality. Additionally, understanding the supply chain dynamics is essential for securing reliable sources of rice and establishing relationships with local farmers. It is also crucial to invest in state-of-the-art machinery that enhances processing efficiency while minimizing potential wastage. This tech-savvy approach not only increases productivity but also addresses quality concerns, providing a competitive edge in the market.

Furthermore, robust management systems are vital for monitoring production and maintaining schedules. Efficient inventory management can significantly affect profitability, necessitating the use of modern software solutions for tracking stock levels and sales trends. A focus on skilled workforce training cannot be understated; equipping employees with the right skills ensures that they can operate machinery safely and efficiently while adhering to quality standards. Lastly, strategic partnerships with distributors can help streamline the journey from farm to table, further enhancing the profitability and sustainability of the rice milling operation.

| Component | Description |

|---|---|

| Location | Close to rice fields for cost efficiency |

| Supply Chain | Strong ties with local farmers for reliable sourcing |

| Machinery | Modern, efficient, and quality-focused equipment |

| Management | Systems for monitoring production and inventory |

| Training | Workforce skilled in safe and efficient operations |

| Partnerships | Collaboration with distributors for market reach |

Essential Technologies and Equipment for Efficient Production

When establishing a rice mill plant, the choice of technologies and equipment can significantly impact both efficiency and output quality. Investing in modern milling machinery is essential for ensuring optimal processing. Key components include:

- Pre-cleaners: Essential for removing impurities from paddy before milling.

- Dehuskers: To efficiently shell the paddy without damaging the rice grains.

- Milling Machines: Including modern roller mills that provide uniformity and improve yield.

- Color Sorters: To eliminate discolored or defective rice, enhancing product quality.

- Packaging Equipment: For efficient filling, sealing, and branding of the final product.

In addition to milling machinery, supporting technologies play a crucial role in optimizing operations. A robust plant layout ensures smooth workflow and minimizes downtime, while advanced sensors and automation systems enhance monitoring and control of key processes. Consider integrating the following:

| Technology | Benefit |

|---|---|

| Automated Control Systems | Streamlines operations and minimizes human error. |

| Energy-Efficient Motors | Reduces operational costs and environmental impact. |

| Data Analytics Software | Facilitates performance monitoring and decision-making. |

Incorporating these technologies not only guarantees a high-quality end product but also positions the rice mill as a competitive player in the market, fostering growth and sustainability.

Financing and Planning Strategies for Sustainable Growth

Building a successful 2-ton rice mill plant requires not just technical prowess but also a robust financial framework and a smart planning strategy. To kickstart this venture on the right foot, consider the following key financial and strategic components:

- Initial Capital Assessment: Estimate the startup costs, including machinery, land, and operational expenses.

- Funding Options: Explore various avenues such as equity investors, bank loans, or government grants tailored for agricultural initiatives.

- Cash Flow Management: Develop a meticulous cash flow projection to ensure sustainable operation and reinvestment capabilities.

- Market Research: Conduct thorough research to identify potential customers, pricing strategies, and distribution channels.

Moreover, a detailed business plan will serve as a roadmap for scaling operations. This includes:

| Plan Element | Description |

|---|---|

| Operational Strategy | Outline processes for sourcing raw materials, production timelines, and quality control measures. |

| Marketing Strategy | Identify branding approaches, advertising platforms, and promotional tactics to reach your target market. |

| Growth Projections | Set realistic sales goals for the first 3-5 years and adjust based on market dynamics and operational efficiencies. |

By meticulously planning and securing adequate financing, investors can pave the way for sustainable growth in their rice milling operations, ensuring that the venture is not only profitable but also resilient in evolving market landscapes.

Insights and Conclusions

launching a 2-ton rice mill plant represents more than just a business venture; it is a strategic investment that can reshape communities and bolster local economies. With the increasing demand for rice and the growing emphasis on processing quality grains, this venture holds the potential to ensure food security while providing employment and supporting farmers. By carefully considering operational logistics, sourcing quality machinery, and implementing effective marketing strategies, entrepreneurs can pave the way for a fruitful enterprise.

As you embark on this journey, remember that success lies not only in the product but in the passion, resilience, and innovation you bring to the table. The rice mill plant stands as a testament to the fusion of tradition with modernity, presenting an opportunity to cultivate both profit and community progress. Now is the time to turn your aspirations into reality and invest in a future that nourishes both the body and the economy. Happy milling!