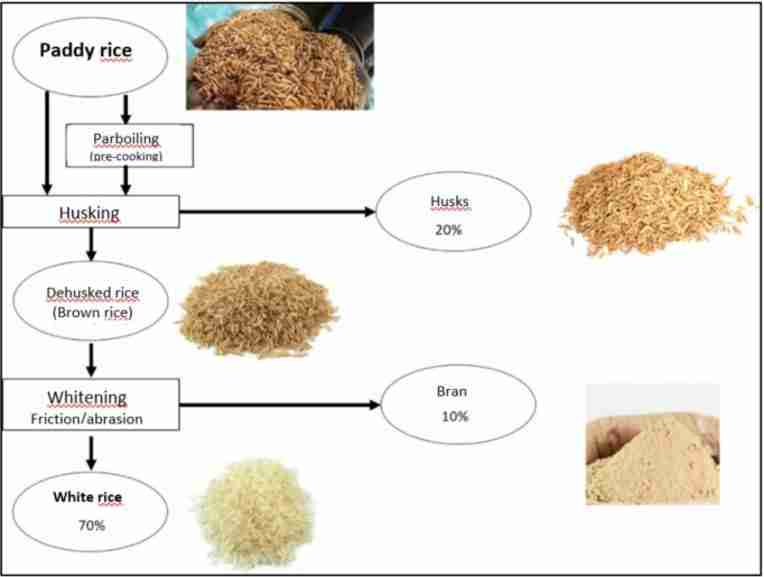

Paddy Processing

The paddy processing of raw paddy rice involves several key steps. Initially, the harvested raw paddy rice undergoes pre-cleaning and cleaning to remove large, medium, and small impurities and stones. It then enters the hulling process where the husk is removed from the paddy, resulting in mostly brown rice and some unhusked paddy. Following this, the mixture enters the separation process, where the hulled brown rice is separated from the unhulled paddy. The unhulled paddy are then lifted back into the hulling machine for a second dehusking process, while the hulled brown rice moves on to the next step, the Rice Processing step.

Transforming Grain: Inside the Paddy Processing Factory

Nestled amidst swaying fields, the Paddy Processing Factory pulses with life. Here, golden grains undergo a meticulous transformation—from uncut stalks to polished rice. With each automated step, tradition meets innovation, ensuring quality and sustainability in every grain.

Transforming Grain: Inside the Paddy Processing Revolution

In the heart of rural landscapes, the paddy processing revolution is reshaping agriculture. Innovative technologies and sustainable practices are transforming raw grain into versatile products, enhancing efficiency while nourishing communities and economies alike.

From Grain to Gain: Inside the Paddy Processing Factory

In the heart of the paddy processing factory, husks fall away like autumn leaves, revealing the glistening grains within. Here, tradition meets technology, transforming raw rice into a staple that fuels lives and cultures around the globe.

Revolutionizing Rice: The Future of Paddy Processing Machines

In the quest for sustainable agriculture, paddy processing machines are evolving. These innovations promise efficiency and reduced waste, transforming how we handle rice production. As technology advances, the future of rice processing is poised for a remarkable revolution.

From Field to Plate: The Art and Science of Paddy Processing

In the journey from field to plate, paddy processing unites art and science. Cultivators harvest golden grains, which undergo meticulous cleaning, milling, and polishing. Each step transforms raw potential into nourishing rice, bridging nature’s bounty with culinary delight.

Transforming Harvests: The Art and Science of Paddy Processing

In the intricate dance of agriculture, paddy processing emerges as a beautiful fusion of art and science. From husking to milling, each step transforms golden grains into the staple foods that nourish millions, reflecting a legacy of tradition and innovation.

Inside the Paddy Processing Plant: Turning Grain into Gold

Inside the Paddy Processing Plant, the journey of grain transforms into golden potential. Each stage, from drying to milling, reveals meticulous artistry, as husks shed to unveil nature's treasure. Here, grains become sustenance, fueling traditions and futures.

Inside the Paddy Processing Factory: Grain to Gourmet Journey

Step inside the paddy processing factory, where raw grains magically transform into gourmet delights. Witness the meticulous journey as husks are removed, grains polished, and flavors enhanced, turning humble rice into a culinary staple cherished worldwide.

Revolutionizing Rice: The Innovative Paddy Processing Machine

In a groundbreaking leap for agriculture, the innovative paddy processing machine is transforming rice production. This cutting-edge technology streamlines processing, reduces waste, and enhances quality, promising a sustainable future for farmers and consumers alike.

From Field to Bowl: Unveiling the Art of Paddy Processing

From sun-drenched fields to the comforting embrace of a rice bowl, the journey of paddy processing is an intricate dance of tradition and modernity. Each step, from harvesting to milling, reveals the artistry and care that transform humble grains into nourishment.