Paddy Processing

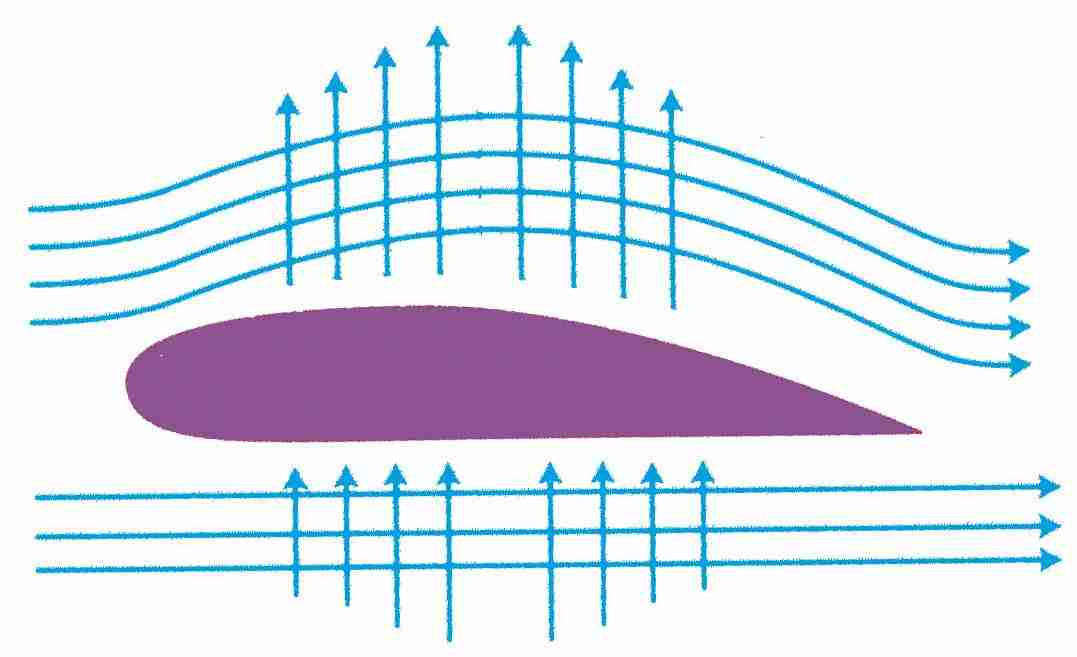

The paddy processing of raw paddy rice involves several key steps. Initially, the harvested raw paddy rice undergoes pre-cleaning and cleaning to remove large, medium, and small impurities and stones. It then enters the hulling process where the husk is removed from the paddy, resulting in mostly brown rice and some unhusked paddy. Following this, the mixture enters the separation process, where the hulled brown rice is separated from the unhulled paddy. The unhulled paddy are then lifted back into the hulling machine for a second dehusking process, while the hulled brown rice moves on to the next step, the Rice Processing step.

From Field to Fork: Inside a Modern Paddy Processing Factory

Nestled amidst lush green fields, a modern paddy processing factory transforms harvested rice into culinary staples. Journey through its sleek assembly lines, where cutting-edge technology meets age-old traditions, ensuring quality from field to fork.

Transforming Grains: The Innovation of Paddy Processing Units

In the heart of agriculture, paddy processing units stand as a testament to innovation. These hubs transform raw grains into nourished staples, blending technology and tradition. As they enhance efficiency, they pave the way for sustainable food security worldwide.

Harvest to Home: The Journey Through a Paddy Processing Plant

Nestled amidst lush green fields, the paddy processing plant hums with life. From harvest to home, grains undergo transformation—winnowing, drying, and milling—each step meticulous, ensuring that every bowl of rice carries the essence of the land.

Transforming Grains: The Journey of a Paddy Processing Unit

In the heart of the countryside, a paddy processing unit transforms humble grains into vibrant rice. The journey begins with freshly harvested paddy, passing through machines that cleanse, hull, and polish, revealing the nutritional treasure hidden within each kernel.

Unlocking Potential: The Journey of a Paddy Processing Unit

In the heart of rural landscapes, a paddy processing unit emerges as a beacon of transformation. It embodies the journey of farmers turned entrepreneurs, harnessing innovation and sustainability to unlock potential, elevate livelihoods, and redefine agriculture.

Streamlining Grain to Plate: The Paddy Processing Journey

From field to fork, the journey of paddy processing unveils a meticulous transformation. Each step—harvesting, milling, and packaging—plays a vital role in enhancing grain quality, ensuring that every bite on our plates tells a story of care and craftsmanship.

Transforming Paddy: The Journey from Field to Plate

From lush green fields to steaming bowls, the journey of paddy is a tale of transformation. Each grain, nurtured by water and sun, transcends its humble origins, embodying culture and sustenance, ultimately connecting farmers and families across the globe.

Transforming Rice: The Art and Science of Paddy Processing

Transforming rice is an intricate dance of art and science, where harvested paddy undergoes careful processing to unlock its potential. From husking to milling, each step not only enhances flavor and texture but also preserves nutrients, bridging tradition with innovation.

Transforming Paddy: A Journey from Field to Flour

"Transforming Paddy: A Journey from Field to Flour" explores the intricate process of turning golden grains into fine flour. From the rhythmic dance of harvesters in sun-kissed fields to the whir of mills, this journey reveals the life cycle of a staple ingredient.

Harvest to Harmony: Inside the Paddy Processing Factory

Nestled amidst lush green fields, the Paddy Processing Factory stands as a bridge between harvest and harmony. Here, the rhythmic sounds of machinery blend with nature’s whispers, transforming golden grains into wholesome rice, ready for the world.