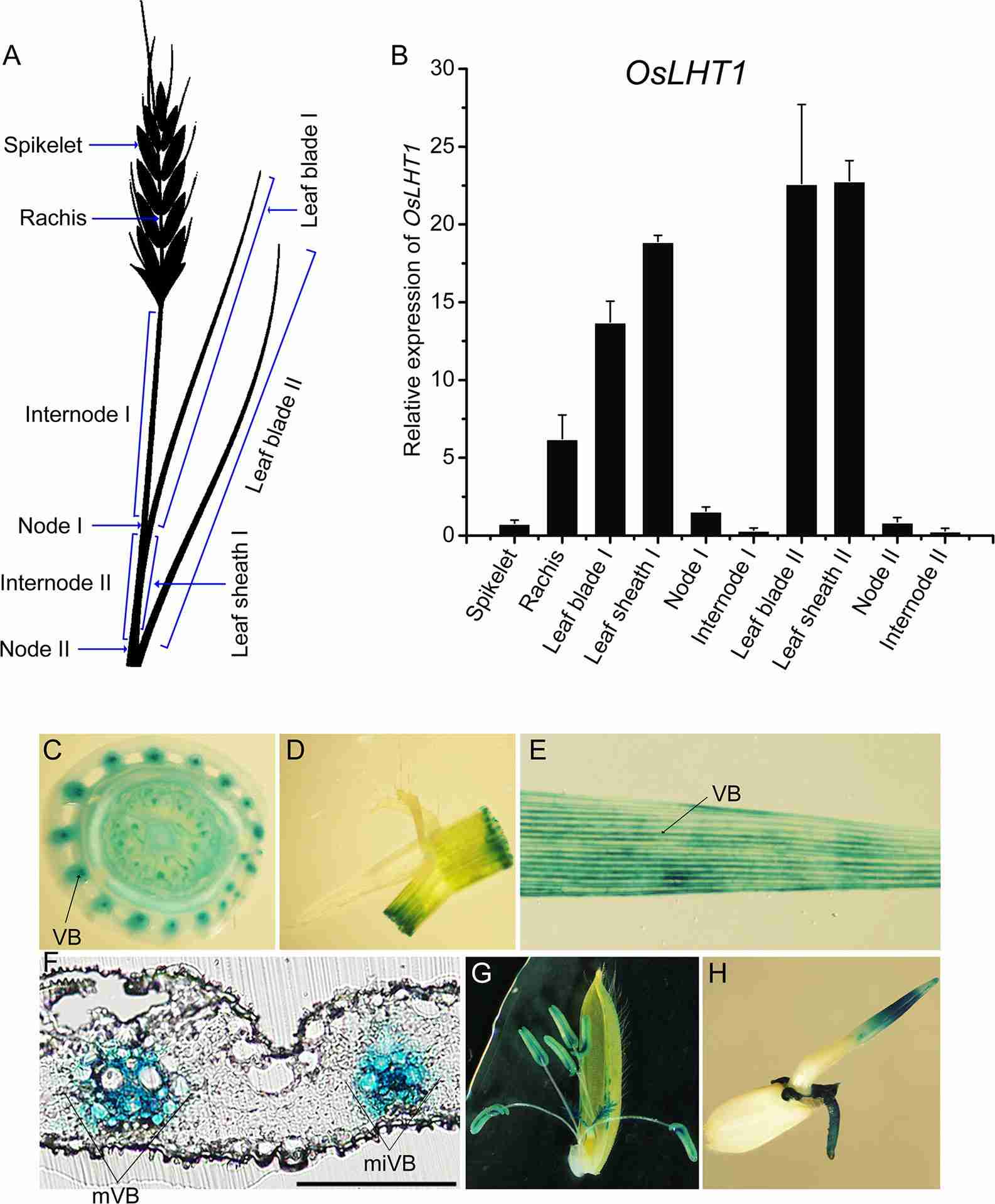

Paddy Processing

The paddy processing of raw paddy rice involves several key steps. Initially, the harvested raw paddy rice undergoes pre-cleaning and cleaning to remove large, medium, and small impurities and stones. It then enters the hulling process where the husk is removed from the paddy, resulting in mostly brown rice and some unhusked paddy. Following this, the mixture enters the separation process, where the hulled brown rice is separated from the unhulled paddy. The unhulled paddy are then lifted back into the hulling machine for a second dehusking process, while the hulled brown rice moves on to the next step, the Rice Processing step.

Transforming Grain: The Impact of Paddy Processing Units

Paddy processing units are revolutionizing grain transformation, enhancing quality and efficiency. By modernizing techniques, these units not only boost yields but also empower farmers, ensuring food security while stimulating local economies.

Unlocking Potential: The Journey of Paddy Processing Plants

In the heart of agricultural landscapes, Paddy Processing Plants emerge as catalysts of transformation. They elevate humble grains into golden kernels, unlocking not just economic potential but also nourishing communities, fostering resilience, and supporting sustainability.

Unlocking Potential: The Future of Paddy Processing Units

In the evolving landscape of agriculture, paddy processing units stand at the forefront of innovation. Harnessing technology and sustainable practices, they promise to transform raw grain into value-added products, unlocking potential for farmers and consumers alike.

Unveiling Paddy Processing: From Field to Finely Milled Rice

Unveiling the journey of paddy processing reveals a fascinating transformation. From lush green fields to finely milled rice, this intricate process highlights the dedication of farmers and the technology that bridges nature and nourishment.

Transforming Grain: A Comprehensive Look at Paddy Processing

Paddy processing is an intricate dance of tradition and technology, where harvested rice undergoes transformation from husk to grain. This comprehensive exploration reveals the vital steps, from milling techniques to quality control, shaping a staple of global cuisine.

Revolutionizing Rice Production: The Future of Paddy Processing

As the world grapples with food security, innovative technologies in paddy processing are emerging to revolutionize rice production. From AI-driven harvesters to eco-friendly milling techniques, these advancements promise efficiency and sustainability for farmers globally.

Transforming Harvests: The Role of Paddy Processing Machines

In the heart of agrarian landscapes, paddy processing machines revolutionize harvests, transforming unrefined grains into market-ready rice. Their precision and efficiency breathe new life into traditional farming, ensuring quality and sustainability in every grain.

Harvest to Hurdles: The Art of Paddy Processing Explained

"Harvest to Hurdles: The Art of Paddy Processing Explained" unveils the intricate journey from golden fields to polished grains. Here, tradition meets technique as farmers navigate the hurdles of drying, milling, and packaging, ensuring quality in every grain.

Unlocking Efficiency: The Role of Paddy Processing Units

Unlocking efficiency in agriculture, paddy processing units play a pivotal role in transforming harvested grain into market-ready products. By streamlining production and minimizing waste, these units not only enhance quality but also boost farmer incomes, fostering a more sustainable industry.

Transforming Grain: The Journey of Paddy Processing Factories

From field to bowl, paddy processing factories transform harvested grains into everyday essentials. This intricate journey involves milling, polishing, and packaging, ensuring each grain retains its nutritional value and meets consumer demands.