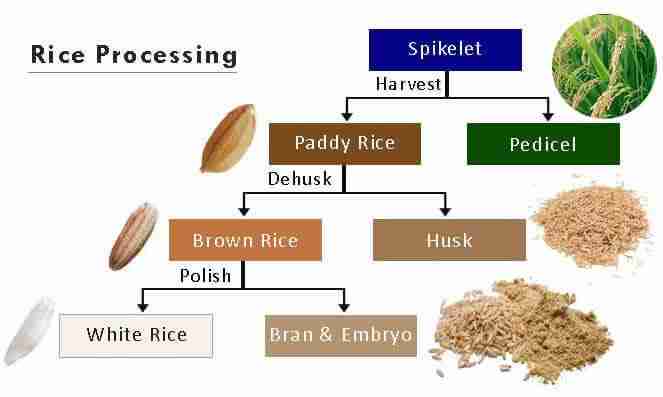

Paddy Processing

The paddy processing of raw paddy rice involves several key steps. Initially, the harvested raw paddy rice undergoes pre-cleaning and cleaning to remove large, medium, and small impurities and stones. It then enters the hulling process where the husk is removed from the paddy, resulting in mostly brown rice and some unhusked paddy. Following this, the mixture enters the separation process, where the hulled brown rice is separated from the unhulled paddy. The unhulled paddy are then lifted back into the hulling machine for a second dehusking process, while the hulled brown rice moves on to the next step, the Rice Processing step.

Transforming Grains: The Innovations in Paddy Processing Units

In the heart of agricultural innovation, paddy processing units are evolving. Advanced technologies streamline transformation, enhancing efficiency and yield. These innovations not only preserve quality but also empower farmers, reshaping the future of rice production.

Unveiling the Future: Innovations in Paddy Processing Machines

The future of rice production is here, as cutting-edge innovations in paddy processing machines revolutionize efficiency and sustainability. These advanced technologies promise to streamline operations, reduce waste, and enhance quality, shaping a new era for farmers worldwide.

Transforming Harvest: Inside a Paddy Processing Factory

At the heart of rural innovation, the paddy processing factory transforms golden grains into nourishment. Machines hum in perfect harmony, while workers orchestrate a ballet of efficiency and care, ensuring quality from field to table in every grain.

Unlocking Potential: The Art of Paddy Processing Plant Operations

In the intricate dance of grain and machine, a paddy processing plant hums with promise. Here, raw rice transforms into culinary staples, unlocking potential through precision, innovation, and the artistry of skilled hands. Each step shines a light on sustainable progress.

Transforming Harvest: Inside the Paddy Processing Factory

In the heart of rural landscapes, the paddy processing factory stands as a beacon of transformation. Here, golden grains undergo a remarkable metamorphosis, from their earthy beginnings to polished rice, ready to nourish the world—an intricate dance of machinery and nature.

From Field to Grain: The Journey of Paddy Processing

From harvesting lush green fields to the rhythmic hum of milling, the journey of paddy processing is a delicate dance. Each grain, once cradled by nature, transforms through husking and polishing, emerging as the staple ingredient that sustains millions.

Inside the Paddy Processing Factory: Harvest to Table Journey

Step inside the Paddy Processing Factory, where grains transform from golden fields to polished rice. Witness the meticulous journey—harvesting, husking, and milling—each stage a testament to tradition and innovation, ensuring quality from farm to table.

Transforming Harvest: An Insight into Paddy Processing Units

In the heart of rural landscapes, paddy processing units transform golden grains into fragrant rice. This intricate journey—from husked to polished—showcases innovative techniques that enhance quality, efficiency, and sustainability in agriculture.

Transforming Paddy: Innovations in Rice Processing Units

In the heart of rural communities, a revolution brews as rice processing units embrace innovative technologies. From solar-powered mills to precision drying systems, these advancements transform paddy into premium rice, ensuring quality and sustainability in every grain.

Transforming Grains: The Innovations of Paddy Processing Units

In the heart of agriculture, paddy processing units are revolutionizing grain transformation. By integrating technology and sustainable practices, these innovations enhance efficiency, reduce waste, and elevate the quality of rice, nourishing communities worldwide.