In a world where convenience often dictates our choices, the culinary landscape is undergoing a remarkable transformation. The humble grain of rice, a staple in diets across the globe, is finding new life thanks to the rise of mini rice milling machines. These compact powerhouses are redefining how we access, process, and enjoy rice, merging tradition with modern efficiency. As households look for ways to simplify meal preparation while retaining freshness and quality, these innovative machines are stepping into the spotlight. Join us as we explore the surge of mini rice milling technology, its impact on food culture, and how it’s unlocking a new world of convenience for home cooks and enthusiasts alike.

The Evolution of Mini Rice Milling Machines and Their Impact on Modern Agriculture

The advancement of technology in agriculture has led to significant transformations in how farmers process their crops. Mini rice milling machines emerged as a practical solution for small-scale farmers, allowing them to mill rice without the high costs associated with larger industrial machines. These compact machines are designed to be user-friendly and efficient, streamlining the milling process while preserving the quality of the rice. With a growing focus on sustainability, these machines have become integral in reducing the carbon footprint of rice milling by minimizing energy consumption and waste.

An analysis of their impact reveals several key benefits for modern agriculture:

- Accessibility: Mini rice milling machines have democratized rice processing, making it easier for smallholder farmers to access mill services.

- Quality Control: Farmers can now ensure a higher standard of rice by milling it on-site, tailored to their market’s specifications.

- Economical: The reduction in dependency on large-scale mills has led to lower transportation costs and increased profits for farmers.

- Community Engagement: These machines foster collaboration among local farmers, creating micro-entrepreneurial opportunities.

the evolution of mini rice milling machines signifies a pivotal change in agricultural practices, favoring local farming economies and enhancing food security. To illustrate this further, consider the following comparison of traditional milling versus mini milling:

| Feature | Traditional Milling | Mini Rice Milling |

|---|---|---|

| Cost | High initial investment | Affordable for small farmers |

| Processing Time | Longer due to batch processing | Faster, on-demand milling |

| Energy Efficiency | High energy consumption | Lower energy usage |

| Quality Control | Variable | Consistent quality |

This clear distinction underscores how the adoption of mini rice milling machines not only supports individual farmers but also contributes to the overall resilience and sustainability of agricultural practices worldwide.

Key Features to Consider When Choosing a Mini Rice Milling Machine

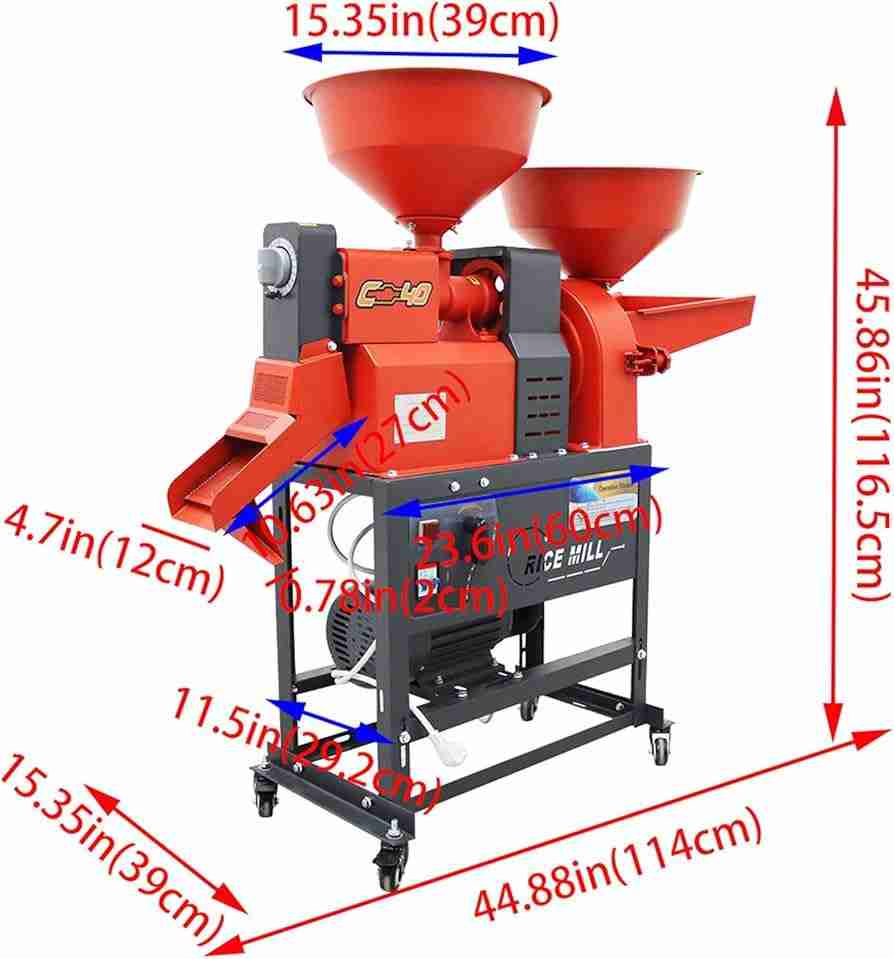

When considering a mini rice milling machine, the first aspect to evaluate is its capacity. This is crucial as it determines how much rice can be processed at a time, impacting both efficiency and productivity. Many models come with different processing capacities, ranging from small-scale machines ideal for home use to larger options suitable for small businesses. Additionally, taking note of the energy efficiency of the machine can lead to long-term savings and an environmentally friendly operation. A model that consumes less power not only helps reduce operational costs but is often designed with advanced technology for enhanced performance.

Furthermore, durability and maintenance should play a significant role in your decision-making process. Investing in a machine made from high-quality materials ensures longevity, allowing for a reliable milling process over the years. Moreover, ease of maintenance is a factor not to overlook; models that offer straightforward cleaning and part replacements will save time and effort. Buyers should also consider the machine’s versatility—some machines are designed to handle different types of grains, expanding their utility beyond just rice. Below is a simple comparison table to aid in evaluating these characteristics:

| Feature | Importance |

|---|---|

| Capacity | Determines processing volume & efficiency |

| Energy Efficiency | Reduces operational costs |

| Durability | Ensures a long-lasting investment |

| Maintenance | Saves time and enhances usability |

| Versatility | Can process various grains |

Optimizing Efficiency: Operational Best Practices for Mini Rice Milling

Maximizing the performance of mini rice milling machines hinges on following operational best practices that streamline processes and enhance output. By implementing a well-structured workflow, operators can ensure that each step from paddy handling to rice packing is optimized for efficiency. Important strategies include:

- Regular Maintenance: Schedule consistent check-ups and cleanings to keep machinery running smoothly and reduce downtime.

- Training Personnel: Equip staff with knowledge about machine operations and troubleshooting to minimize errors and inefficiencies.

- Quality Control: Establish a robust quality check process at different stages of milling to maintain high standards and eliminate waste.

- Efficient Workflow Design: Lay out the milling area to promote a logical flow of materials, reducing unnecessary movement and time.

The choice of machinery also plays a significant role in operational efficiency. Mini rice milling machines equipped with advanced technology can drastically reduce processing time and improve yield. To illustrate this, consider a comparative table showcasing typical input and output metrics for standard and advanced mini milling machines:

| Feature | Standard Mini Mill | Advanced Mini Mill |

|---|---|---|

| Processing Time (hrs/ton) | 4 | 2.5 |

| Yield Efficiency (%) | 65 | 75 |

| Energy Consumption (kWh) | 150 | 100 |

By embracing these operational best practices and investing in advanced machinery, those in the mini rice milling sector can foster a more productive and sustainable business model, ensuring they remain competitive in a rapidly evolving market.

Future Trends in Mini Rice Milling Technology and Sustainable Practices

The future of mini rice milling technology is poised to embrace innovations that significantly enhance efficiency and reduce environmental impact. One of the key trends is the integration of smart technology, which will enable farmers to monitor and control mill operations using mobile applications. This capability not only streamlines the milling process but also allows for real-time adjustments to optimize output quality. Additionally, these advanced systems can feature sensor-based technologies that assess grain quality, ensuring that only the best produce is processed, thus minimizing waste. As sustainability becomes central to agriculture, the design of mini rice mills is likely to shift towards modular and portable units that can be easily relocated, facilitating the use of local resources and reducing transportation emissions.

Moreover, the incorporation of renewable energy sources into milling operations is gaining traction. Many manufacturers are exploring solar-powered milling systems which can operate in off-grid locations, further promoting accessibility and efficiency. With the growing emphasis on eco-friendly practices, we may also see an uptick in the use of by-products generated from rice milling, such as rice husk and straw, being repurposed for animal feed or biodegradable packaging. Collaboratively, these trends will underpin a transition toward a more sustainable agronomy landscape, reducing the carbon footprint associated with traditional rice milling. As the industry continues to innovate, embracing these practices will be crucial in meeting the agricultural demands of future generations.

| Trend | Description |

|---|---|

| Smart Technology | Mobile apps for remote monitoring and control of milling operations. |

| Sensor-based Quality Control | Real-time assessment of grain quality for optimized processing. |

| Renewable Energy | Solar-powered mills for off-grid and sustainable operations. |

| By-product Utilization | Repurposing waste like rice husk and straw for eco-friendly products. |

Wrapping Up

the rise of mini rice milling machines symbolizes not just a technological advancement but a profound shift in how we approach food production and sustainability. These compact marvels are bridging the gap between traditional practices and modern efficiency, empowering small-scale farmers and entrepreneurs to unlock new levels of convenience and productivity. As we continue to explore innovative solutions for agricultural challenges, the future looks bright for those seeking to enhance food security and promote local economies. Embracing such innovations can lead to a more resilient food system, where every grain of rice tells a story of progress and possibility. The journey toward streamlined agriculture is just beginning, and the humble mini rice milling machine is leading the way.