In the heart of our daily sustenance lies a process both ancient and sophisticated—cereal milling. This art, often overlooked, is a delicate dance between tradition and innovation, where grains are transformed from their raw, rustic state into the finely milled flours and cereals that nourish our bodies. Behind the seemingly simple act of grinding grain lies a complex interplay of science and craftsmanship, revealing the secrets that unlock flavors, textures, and nutritional value. From the rhythmic whir of modern machinery to the timeless techniques of artisanal milling, this article delves into the nuanced world of cereal milling, exploring its historical roots, contemporary advancements, and the vital role it plays in our food systems. Join us as we uncover the layers of knowledge and skill that make milling not just a process, but an art form essential to the fabric of life.

Grain Composition Unveiled Understanding the Building Blocks of Cereal Milling

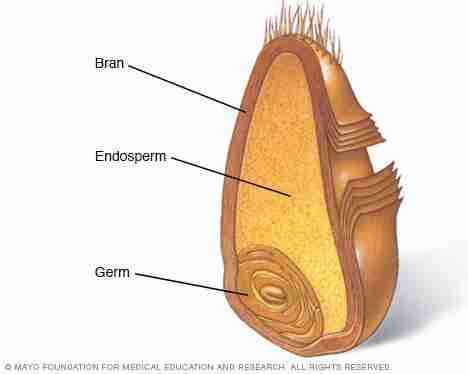

The journey of grain from field to flour is a fascinating interplay of nature, technology, and tradition. At the heart of this process lies a deep understanding of grain composition, which serves as the foundation for quality cereal milling. The essential components of grains—such as starch, protein, lipids, vitamins, and minerals—play pivotal roles in determining the milling characteristics and end products. By analyzing these elements, millers can tailor their processes to enhance yield, texture, and nutritional value.

Each type of grain brings a unique blend of these building blocks, influencing the milling technique and the resulting flour properties. For instance, the hardness of wheat is crucial for producing high-quality bread flour, while softer grains are ideal for cakes and pastries. Additionally, understanding the levels of gluten creates pathways for bakers to achieve their desired dough strength and elasticity. The following table provides a snapshot of common grains and their notable compositional features:

| Grain Type | Main Component | Primary Use |

|---|---|---|

| Wheat | Protein (Gluten) | Bread |

| Rice | Starch | Side Dishes |

| Corn | Carbohydrates | Snacks/Flour |

| Oats | Beta-Glucan | Breakfast Cereals |

Moreover, the milling process itself transforms these raw grains into versatile products. Techniques such as grinding, sifting, and blending are employed to produce flour with distinct characteristics suited for various culinary tasks. The intricate balance of grain composition not only affects the milling efficiency but also the flavor and functionality of the final products, ensuring that cereal milling remains both an art and a science.

The Milling Process Demystified Exploring Techniques for Optimal Grain Separation

The milling of grain is a fascinating blend of art and science, relying heavily on understanding the structure of the grain kernel and the desired end product. To achieve optimal separation, millers employ a variety of techniques that cater to different grains, moisture levels, and processing goals. Key methods include:

- Break Rollers: These are the primary means of initial grain crushing, where the outer husk is removed, making way for efficient separation.

- Reduction Rollers: Once broken, the grain undergoes finer milling to produce flour or meal through a series of adjustments in roller spacing.

- Destoning: Essential for ensuring purity, destoning involves systems designed to remove impurities like stones, which can damage milling equipment.

Additionally, the temperature and humidity of the milling environment play a crucial role in the process. Maintaining an optimal moisture content allows better separation and reduces the risk of dust formation. Various methods are often applied concurrently, as emphasized by the milling pyramid structure, which categorizes both the physical processes and desired outputs:

| Process Type | Function |

|---|---|

| Pre-Cleaning | Removes foreign materials before milling |

| Conditioning | Adjusts moisture for optimal milling |

| Grinding | Reduces grain to flour or meal |

This intricate dance between technique and technology truly exemplifies the mastery involved in cereal milling, turning raw grains into the staple ingredients of countless recipes.

Quality Control in Every Grain Ensuring Consistency and Safety in Production

In the intricate world of cereal milling, the journey from farm to table hinges on stringent quality control measures that govern every aspect of production. Every grain is not only an agricultural product but a potential vector for inconsistencies if not handled with meticulous attention. To maintain the highest standards, multi-stage testing is employed, encompassing:

- Visual inspections for discoloration and contaminants

- Moisture content analysis to prevent spoilage

- Grain hardness tests to ascertain milling quality

This labor-intensive approach ensures that cereal products retain their nutritional integrity and meet safety regulations, cultivating trust with consumers who expect nothing less than the best.

The implementation of technology further amplifies quality assurance processes, harnessing innovations such as sensors and automated systems designed to detect irregularities in real-time. These systems allow for immediate adjustments, fostering a consistent product output through precise control of milling conditions. Below is a simple illustration of the key technology enhancements in quality control:

| Technology | Purpose |

|---|---|

| Moisture Sensors | To ensure optimal moisture levels |

| Grain Analysis Software | To analyze quality metrics in real-time |

| Automated Sorting Machines | To eliminate impurities and discolored grains |

By marrying these advanced methods with traditional craftsmanship, producers not only enhance the safety of their products but also stabilize quality across batches, ensuring that each package of cereal is as wholesome as the last.

Innovations in Milling Technology Enhancing Efficiency for the Modern Millhouse

Recent advancements in milling technology have transformed the landscape of grain processing, enabling millhouses to operate with unprecedented efficiency and precision. Integrating automated control systems allows mills to monitor and adjust the milling process in real time, ensuring optimal grain extraction and quality. Additionally, the implementation of high-performance milling equipment such as roller mills and pneumatic conveyors minimizes energy consumption and maximizes throughput. These innovations not only boost productivity but also enhance the consistency of the final product, catering to the increasingly discerning tastes of consumers.

Furthermore, the incorporation of data analytics and machine learning into milling operations has revolutionized the way millers approach their work. By analyzing vast amounts of data, millhouses can forecast demand, manage inventory effectively, and tailor their production processes to meet specific market needs. Factors such as grain moisture content can be monitored with sensors, allowing for adjustments to milling parameters that ensure high-quality output. As a result, millers are not only optimizing their operations but also paving the way for a sustainable future through the reduction of waste and energy usage.

Wrapping Up

As we draw the curtain on our exploration of “Unlocking Grain Secrets: The Art and Science of Cereal Milling,” it becomes clear that this intricate process is more than just a means to an end. It is a delicate dance between raw nature and advanced technology, steeped in tradition yet constantly evolving. Each grain tells a story, from the fields where it’s cultivated to the mills where it’s transformed into the flours and cereals that nourish us daily.

By delving into the nuances of cereal milling, we appreciate the craftsmanship behind our staple foods and recognize the innovation that drives this essential industry forward. As consumers, understanding these complexities not only enhances our gratitude for what fills our plates but also empowers us to make informed choices about the food we consume.

Whether you are a food connoisseur, a health enthusiast, or simply curious about the journey of your breakfast cereal, the world of grain milling invites you to delve deeper. As the millstones turn and the science unfolds, each bite carries with it the artistry of those dedicated to unlocking the secrets of grain. As we continue to cultivate our relationship with food and sustainability, let us remain curious architects of our culinary futures.