Unlocking Grain Potential: The Art of Cereal Milling

In the heart of agricultural innovation lies a time-honored process that transforms humble grains into the foundational ingredients of our daily sustenance. Cereal milling, an intricate art and science, serves as the bridge between field and table, where the potential of wheat, corn, rice, and other cereals is meticulously unlocked. As we delve into the world of milling, we explore not only the techniques that have evolved over centuries but also the modern advancements that promise to enhance quality and sustainability in food production. This article invites you on a journey through the history, craftsmanship, and technology of cereal milling—an industry that not only nurtures our bodies but also connects us to the earth. Join us as we unravel the secrets of this vital process and discover how unlocking the potential of grain shapes our culinary landscapes and influences our future.

Exploring Grain Varieties for Optimal Milling Results

Unlocking the true potential of grains begins with an in-depth understanding of their unique properties. Varieties such as whole wheat, spelt, and barley each bring something distinct to the milling process. Whole wheat, for instance, is revered for its robust flavor and high fiber content, making it ideal for health-conscious consumers. Meanwhile, spelt is an ancient grain known for its nutty taste and easier digestibility, appealing to the modern palate. Lastly, barley offers a diverse range of uses, from traditional malt to healthful flours that can enrich various baked goods.

To achieve optimal milling results, it is essential to consider several critical factors when selecting grain varieties. Key characteristics that influence the end product include:

- Protein Content: Higher protein levels can result in stronger gluten formation, impacting texture.

- Moisture Levels: Proper moisture content ensures efficient milling and prevents spoilage.

- Kernel Hardness: Hard grains require more milling energy but yield finer flour.

A comparison table can help illustrate the differences among common grains used in milling:

| Grain Variety | Protein Content (%) | Flavor Profile | Common Uses |

|---|---|---|---|

| Whole Wheat | 12-15 | Earthy, Rich | Breads, Pastries |

| Spelt | 10-14 | Nutty, Sweet | Breads, Pancakes |

| Barley | 10-12 | Malty, Mild | Soups, Flours |

Understanding the Milling Process and Its Impact on Flour Quality

The milling process is a captivating interplay of science and artistry, where raw grains transform into finely milled flour ready for baking. At its core, milling involves several stages, including cleaning, conditioning, and grinding. Each of these steps is meticulously designed to optimize the extraction of flour while preserving the intrinsic qualities of the grain. Factors such as moisture content, grain hardness, and milling techniques significantly influence the final product’s texture and nutritional content. Understanding these components is essential for maximizing the potential of each grain type, whether it’s hard wheat, soft wheat, or specialty grains like spelt and rye.

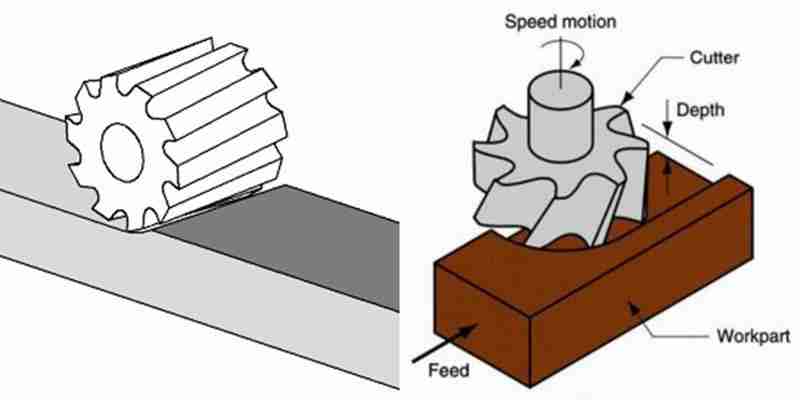

Moreover, the impact of the milling process on flour quality extends beyond mere appearance or texture. Different milling techniques, such as stone milling, hammer milling, and roller milling, produce flours with varying granulation and functional properties. The choice of milling method affects the protein content, ash levels, and even the fiber content, which are vital in determining how flour will behave in recipes. To illustrate this link between milling method and flour quality, refer to the table below:

| Milling Method | Protein Content (%) | Fiber Content (%) |

|---|---|---|

| Stone Milling | 10-12 | 4-5 |

| Hammer Milling | 8-10 | 1-2 |

| Roller Milling | 11-13 | 2-3 |

This understanding underscores the importance of choosing the right milling method according to the end use of the flour. Distinct preferences in baking, cooking, and nutrition call for a tailored approach to grain milling, ensuring that the desired qualities—be it strength for bread or tenderness for pastries—are achieved. By appreciating the intricacies of milling and its profound impact on flour characteristics, both producers and consumers can unlock the full potential of grains, leading the way to a more flavorful and nutritious culinary experience.

Innovative Techniques for Enhancing Cereal Milling Efficiency

In the quest for maximized efficiency, cereal milling operations are turning to a range of innovative techniques that streamline production and enhance grain processing. One such method is the adoption of smart milling technology, which utilizes advanced algorithms and machine learning to monitor grain properties in real-time. By analyzing factors such as moisture content and kernel hardness, these systems allow millers to adjust settings on the fly, ensuring optimal performance and minimal waste. Additionally, the integration of automated sorting machines helps in the pre-milling phase by swiftly categorizing grains based on size and quality, significantly reducing human error and manual labor costs.

Another breakthrough lies in sustainable milling practices, which not only improve efficiency but also cater to the growing demand for environmentally friendly operations. Employing energy-efficient milling equipment can cut down on power consumption, while using by-products such as bran for animal feed or biofuel contributes to a circular economy within the milling industry. To further illustrate these advancements, consider the comparison of traditional versus modern milling techniques in the table below:

| Technique | Traditional Milling | Modern Milling |

|---|---|---|

| Energy Consumption | High | Low |

| Precision | Manual Adjustments | Automated Systems |

| Quality Control | Limited | Real-Time Monitoring |

| Waste Management | Minimal | Integral to Process |

Sustainable Practices in Cereal Milling for a Greener Future

The journey towards environmentally friendly cereal milling begins with sourcing ingredients from local, organic farms. Supporting local agriculture not only reduces carbon emissions associated with transportation but also promotes biodiversity and soil health. Milling companies are increasingly adopting energy-efficient technologies that minimize waste and lower energy consumption. By utilizing equipment that relies on renewable energy sources, such as solar or wind power, mills can significantly reduce their carbon footprint and contribute to a greener economy. Other practices include water conservation techniques, which ensure that milling operations do not deplete local water sources, thus maintaining the balance of ecosystems.

In addition to eco-friendly sourcing and energy practices, the implementation of waste management systems is crucial in cereal milling. By repurposing by-products, such as bran and germ, mills can create valuable ingredients for animal feed or natural fertilizers. This not only minimizes waste but also adds value to the milling process. Collaborative efforts within the community can further enhance these sustainable practices. Mills can engage in partnerships that promote grain sharing and redistribution, ensuring that all harvested grains are utilized. The following table summarizes some key sustainable practices in cereal milling:

| Practice | Benefit |

|---|---|

| Local sourcing | Reduces transport emissions |

| Energy-efficient technology | Lower energy consumption |

| Water conservation | Protects local water sources |

| Waste repurposing | Minimizes waste, adds value |

| Community partnerships | Enhances resource efficiency |

Insights and Conclusions

As we conclude our exploration into the intricate world of cereal milling, it becomes clear that this age-old art is more than just a process; it is a vibrant intersection of science, tradition, and innovation. With every kernel transformed into flour, we witness the metamorphosis of grains that serve as the foundation of countless culinary delights. The meticulous techniques employed by millers not only unlock the potential of the grain but also connect us with our agricultural roots and the global food landscape.

As we look to the future, the ongoing advancements in milling technology and sustainability practices present exciting opportunities for both producers and consumers alike. It is a journey that invites us all to appreciate the craftsmanship behind our daily staples, fostering a deeper understanding of the origins of our food. So, the next time you savor a loaf of bread or a bowl of cereal, remember the skilled hands and innovative minds that have worked tirelessly to bring these grains to your table. In every bite lies a story, a legacy, and the promise of a bountiful harvest yet to come.