In a world where breakfast often sets the tone for the day, few staples have captured our morning rituals quite like cereal. With its colorful boxes and crunchy textures, cereal is a beloved choice for many, but have you ever pondered the journey of those toasted flakes from field to bowl? Entering the fascinating realm of cereal processing reveals a complex symphony of science and innovation, where agriculture, engineering, and nutrition converge. In this article, we embark on a crunchy exploration of the mechanisms behind cereal production, unraveling the intricacies of milling, cooking, and fortification. Join us as we dissect the methodologies that ensure every bite is not just a morsel of flavor but a carefully crafted blend of health and convenience, uncovering the hidden layers of this breakfast phenomenon.

Understanding the Raw Ingredients: From Grain to Flake

At the heart of cereal production lies an array of raw ingredients, each meticulously sourced to create the crunchy breakfast staples we know and love. The journey begins with the selection of grains, where wheat, corn, oats, and rice reign supreme. These foundational ingredients are not just chosen for their taste but also for their nutritional profiles and functional properties that influence the final product. Once harvested, the grains undergo a series of processes, including cleaning, conditioning, and milling, which prepare them for further transformation. Each step is essential in ensuring that every flake that emerges retains the integrity of the grain while enhancing flavor and texture, setting the stage for the cereal-making magic that follows.

After milling, grains are often subjected to steam treatment or flaking to unlock their full potential. This involves cooking the grains under controlled heat and pressure, making them easier to digest and enhancing their flavor. Following this, the grains are shaped and dried, leading to the creation of those familiar crunchy flakes. The transformation from humble grain to vibrant cereal is not merely mechanical; it’s a finely-tuned science involving the interplay of starch gelatinization, protein denaturation, and even the Maillard reaction for flavor development. To illustrate the journey of a single grain to its crunchy flake form, consider the following table outlining key stages in this conversion process:

| Stage | Description |

|---|---|

| Harvesting | Grains are collected and prepared for initial processing. |

| Cleansing | Grains are cleaned to remove debris and impurities. |

| Conditioning | Moisture levels are adjusted for optimal milling. |

| Milling | Grains are ground to release their inner kernels. |

| Flaking | Cooked grains are pressed into thin, crunchy flakes. |

The Maillard Reaction: Creating Flavor and Color in Cereal

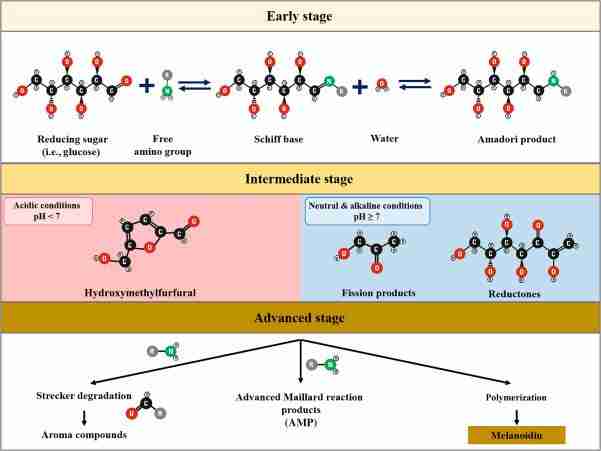

The Maillard reaction is an intricate dance of chemistry that takes place during the processing of cereal grains, transforming humble ingredients into a symphony of flavor and aroma. As these grains are subjected to heat, the amino acids and sugars present engage in a series of complex reactions. This is where cereal undergoes a delightful metamorphosis, moving from the bland to the extraordinary. The combination of heat, moisture, and time allows for the development of golden-brown hues and rich flavors that are characteristic of toasted cereals. Key elements of this fascinating phenomenon include:

- Aroma development: The reaction produces a variety of volatile compounds that contribute to the inviting smell of freshly toasted cereals.

- Flavor complexity: A range of savory and sweet flavors emerge, enhancing the overall taste profile with nutty, caramel-like notes.

- Color transformation: The formation of melanoidins gives cereals their appealing brown color, a visual cue that denotes flavor depth.

Understanding the Maillard reaction reveals why color and flavor are so intertwined in our favorite breakfast bowls. This process not only enriches the sensory experience but also impacts the nutritional qualities of the cereals we consume. During roasting, the breakdown of proteins can lead to the formation of new antioxidants that benefit health. In addition to these advantages, the balance of variables such as temperature and moisture content is crucial. Below is a table summarizing the ideal conditions for optimizing the Maillard reaction in cereal processing:

| Factor | Ideal Range |

|---|---|

| Temperature | 120°C – 180°C |

| Time | 10 - 60 minutes |

| Moisture Content | 10% – 20% |

Nutritional Transformation: Balancing Health and Taste

In the world of cereals, achieving a symbiotic relationship between taste and health is both an art and a science. Modern processing techniques are designed to enhance the nutritional profile of cereals while preserving or even boosting their flavor. What was once considered a mundane breakfast option has now evolved into a delightful culinary experience, combining whole grains, fruits, nuts, and a myriad of flavorings that can appeal to diverse palates. The integration of superfoods like chia seeds, quinoa, and oats into cereal formulations not only boosts the fiber content but also introduces a satisfying crunch and a substantial nutritional punch.

Moreover, innovative methods such as extrusion and toasting play pivotal roles in crafting textures that captivate the consumer’s taste buds. These techniques allow for a wide range of creations, from light and airy flakes to dense clusters, all while utilizing natural sweeteners and flavor enhancers that minimize the need for artificial additives. Here’s a glimpse into popular elements incorporated during cereal processing:

| Ingredient | Benefit |

|---|---|

| Whole Grains | High in fiber, supports digestion |

| Nuts & Seeds | Protein-rich, healthy fats for satiety |

| Dried Fruits | Natural sweetness, boosts vitamins |

| Natural Sweeteners | Reduced sugar content, healthier option |

Sustainable Practices in Cereal Processing: A Future-Focused Approach

As the world transitions towards eco-consciousness, cereal processing stands at the forefront of sustainable innovation. Modern techniques are revolutionizing the way we approach cereal production by prioritizing practices that reduce waste and enhance resource efficiency. This includes the adoption of energy-efficient machinery, which minimizes electricity usage while ensuring optimal output. Additionally, innovative processing methods such as extrusion and steam cooking not only preserve the nutritional integrity of grains but also cut down on water consumption significantly. By embracing these advancements, manufacturers can reduce their carbon footprint while delivering high-quality products.

Another pivotal area of focus is the sourcing and utilization of local grains, which cultivates community support and reduces transportation emissions. This approach not only fosters regional economies but also guarantees freshness in the final products. The burgeoning trend of bio-based packaging is another commendable practice making waves in the industry. By shifting away from conventional plastic options to biodegradable alternatives, companies can further their commitment to environmental sustainability. Below is a concise comparison of traditional versus sustainable practices in cereal processing:

| Aspect | Traditional Practices | Sustainable Practices |

|---|---|---|

| Energy Consumption | High | Minimized with efficiency |

| Waste Generation | Significant | Reduced through innovative methods |

| Packaging Materials | Plastic-based | Biodegradable or recyclable |

| Grain Sourcing | Global | Local and community-supported |

Future Outlook

As we reach the end of our crunchy exploration into the intricate world of cereal processing, it’s clear that the journey from field to bowl is a fascinating blend of science, innovation, and tradition. Each flake and puff tells a story, shaped by the meticulous techniques developed over decades—techniques that transform simple grains into breakfast staples enjoyed by millions.

From the careful selection of raw materials to the precise engineering of production methods, the world of cereal is a testament to human ingenuity. As we consider the diverse nutritional profiles and flavor profiles, we find a realm where health meets enjoyment, making breakfast an experience of both sustenance and pleasure.

So the next time you pour that bowl of cereal, remember the science that has put each crispy morsel in your hands. With every bite, you’re not just savoring a meal—you’re participating in a complex dance of chemistry and craftsmanship that continues to evolve. And as we look to the future, the possibilities for innovation in cereal processing are as vast and varied as the grains themselves.