The Art and Science of Cereal Milling: From Grain to Flour

Nestled within the heart of our daily sustenance lies a process both ancient and innovative—the transformation of humble grains into the versatile flour that nourishes our world. The journey from field to table is more than just a simple transformation; it is a harmonious blend of art and science that has evolved over centuries. From the rhythmic whir of milling machinery to the meticulous selection of grain varieties, every step in the milling process is a testament to human ingenuity and the natural beauty of our agricultural bounty. In this exploration, we will delve into the intricate techniques and technological advancements that define modern milling, shedding light on the delicate balance between preserving the grain’s integrity and enhancing its functionality. Join us as we unravel the complexities behind this essential process, revealing how the mastery of milling artistry converges with the precision of scientific principles, ultimately paving the way for the flour that fuels our culinary creativity.

Exploring the Grain: Understanding the Diverse Types of Cereal

Grains are the foundation of our food system and come in an astonishing variety of types, each with unique characteristics that influence everything from flavor to texture. The most common cereal grains include wheat, corn, rice, barley, and oats. These staples are not only integral to our diets but also serve as a canvas for culinary creativity. Understanding the diverse types of cereal allows millers to select the appropriate grain for specific flour applications, ensuring that each product caters to particular needs, whether for baking bread, crafting pastries, or producing breakfast cereals.

Each grain type possesses distinct properties that contribute to its milling qualities. For instance, the protein content in wheat varies significantly, affecting gluten formation which is crucial for bread-making. Conversely, corn is celebrated for its versatility, offering options for everything from cornmeal to masa harina, pivotal in Latin American cuisine. To further illustrate these differences, the table below highlights key attributes of popular cereal grains:

| Grain | Primary Use | Key Characteristics |

|---|---|---|

| Wheat | Baking Bread | High in gluten; versatile |

| Corn | Polenta, Tortillas | Sweet flavor; non-gluten |

| Rice | Side Dishes, Sushi | Gluten-free; neutral flavor |

| Barley | Soups, Stews | Nutty taste; chewy texture |

| Oats | Breakfast Cereals | High in fiber; smooth texture |

Each of these grains contributes to the rich tapestry of our meals, providing essential nutrients and flavors that enhance our culinary experiences. As the milling process transforms these whole grains into fine flour, understanding these characteristics is essential for millers and bakers alike, enabling them to create products that not only satisfy but also inspire culinary innovation.

Mastering the Milling Process: Techniques that Transform Grain into Flour

Understanding the milling process requires an appreciation of both the artistry involved and the scientific principles at play. Grain refinement begins long before the first kernel enters the mill; selection is vital. The quality of grain—whether it’s wheat, corn, or rye—plays a pivotal role in the resulting flour. Once chosen, the grains are cleaned meticulously to remove any impurities that could affect flavor or texture. This initial step is crucial, as contaminants can not only spoil the flour but also hinder the milling process. After cleaning, the grains undergo a series of transformations including tempering and grinding, each step designed to maximize yield and enhance the flour’s characteristics.

During the grinding process, various techniques come into play that highlight the complexity of milling. Modern mills may employ different types of machinery such as stone mills, hammer mills, or roller mills, each imparting its unique touch to the flour. The choice of milling method influences the texture and flavor profile of the final product. Flour types range in extraction rates—from whole grain to refined—determined by how much of the grain is retained during the milling process. Here’s a simple breakdown of some common flour types and their characteristics:

| Flour Type | Extraction Rate (%) | Characteristics |

|---|---|---|

| Whole Wheat | 100 | Contains all parts of the grain; rich in nutrients. |

| All-Purpose | 80 | Versatile; balance of protein and gluten. |

| Pastry Flour | 70 | Soft, low-protein; ideal for pastries and pies. |

| Gluten-Free | Variable | Blends of alternative grains; caters to dietary needs. |

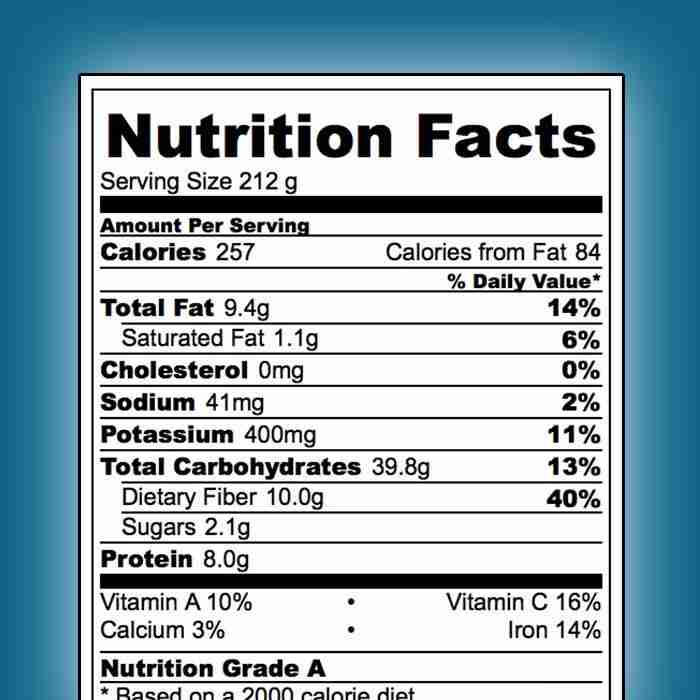

Nutritional Profile of Flour: Balancing Health and Culinary Performance

The journey from grain to flour does not merely transform the physical form of cereal; it also alters its nutritional profile significantly. Flour, as a foundational ingredient in diverse culinary traditions, offers an array of nutrients that can contribute to a balanced diet. The composition can vary widely depending on the type of grain used and the milling process employed. For instance, while whole grain flours retain the bran and germ, rich in fiber, vitamins, and minerals, refined flours predominantly consist of the endosperm, thereby losing many of these healthful components.

When assessing the nutritional benefits of flour, consider these key components:

- Carbohydrates: The primary energy source, playing a crucial role in fueling both physical and mental activities.

- Protein: Essential for growth and repair, with varying levels found in different flour types, such as stronger protein in bread flour.

- Vitamins and Minerals: B vitamins like thiamine and niacin are often abundant, aiding metabolism and overall health.

- Fiber: Particularly present in whole grain flours, promoting digestive health and lending a sense of fullness.

To further understand the differences in nutritional content, the following table compares common flour types:

| Flour Type | Calories (per 100g) | Protein (g) | Fiber (g) |

|---|---|---|---|

| All-Purpose Flour | 364 | 10.3 | 2.7 |

| Whole Wheat Flour | 340 | 13.2 | 12.2 |

| Almond Flour | 581 | 21.1 | 10.4 |

| Coconut Flour | 443 | 18.0 | 38.0 |

Understanding these variations empowers consumers to make more informed choices that align with their health goals while still enjoying the myriad culinary possibilities flour brings. Whether you are a seasoned baker or a casual cook, being aware of the nutritional attributes of flour can elevate both your health and your dishes.

Innovations in Cereal Milling: Embracing Technology for Sustainable Practices

In the quest for greater efficiency and sustainability, cereal milling has undergone a remarkable transformation driven by cutting-edge technology. Advanced machinery and smart systems are now being integrated into the milling process to minimize waste and enhance product consistency. Robotics and IoT (Internet of Things) are playing pivotal roles, allowing for real-time monitoring and adjustments to ensure optimal performance. These innovations lead to significant reductions in energy consumption, which is essential for an industry facing increasing scrutiny over its environmental impact. Some of the latest trends include:

- Automated Milling Systems: These systems streamline operations by automating tasks that were once time-consuming and labor-intensive.

- Data Analytics: Using big data to analyze crop quality and yield, ensuring the best inputs for milling.

- Sustainable Packaging Solutions: Innovations in biodegradable and recyclable materials to reduce landfill waste.

Moreover, new milling techniques, such as high-speed impact milling, are not only enhancing flour quality but also significantly reducing energy demands. Milling plants are starting to incorporate renewable energy sources, like solar and wind, into their operations to further shrink their carbon footprint. The following table illustrates the contrasting benefits of traditional vs. modern milling practices:

| Aspect | Traditional Milling | Modern Milling |

|---|---|---|

| Energy Efficiency | Low | High |

| Waste Generation | Higher | Lower |

| Quality Control | Manual | Automated |

| Product Range | Limited | Diverse |

These technological advancements not only reflect a commitment to sustainability but also signify a shift toward a more responsible approach to food production. By embracing these innovations, cereal milling is poised to meet the challenges of the future while ensuring high-quality products for consumers around the world.

Insights and Conclusions

As we draw the curtain on our exploration of the intricate journey from grain to flour, it becomes clear that cereal milling is both an art and a science, seamlessly intertwining tradition with technology. Each kernel tells a story, a testament to the agricultural practices that nurture it and the innovative processes that transform it. From the rhythmic sound of milling machines to the subtle alchemy of blending different grains, every stage is a delicate balance of precision and creativity.

As consumers, we often take for granted the finely milled flour that finds its way into our kitchens, the result of countless hours of expertise and dedication. Understanding the meticulous methods behind cereal milling not only enriches our appreciation for this staple ingredient but also connects us to the broader tapestry of food production.

In a world where the origins of our food can sometimes feel lost, the journey of flour serves as a reminder of the blend of nature and craft that underpins our meals. As you sift through your own culinary creations, may you carry a newfound respect for the grains and the passionate artisans behind the scenes, ensuring that each bite is a masterpiece in its own right. So, the next time you reach for that bag of flour, remember the art and science that brought it from field to table—it’s a narrative worth savoring.