Introduction: Grinding Growth: The Art and Science of Maize Milling

In the world of food production, few grains are as fundamental to daily diets as maize. From the bustling markets of sub-Saharan Africa to the heartland of the American Midwest, this versatile grain has transcended cultural boundaries and culinary practices. Yet, beneath the vibrant yellow kernels lies a complex interplay of tradition and technology—an intricate ballet of grinding and milling that transforms raw maize into essential products like flour, meal, and grits. “Grinding Growth: The Art and Science of Maize Milling” invites you to explore the fascinating journey of maize from field to flour, delving into the techniques both ancient and modern that shape this critical industry. By examining the nuances of milling processes, the impact of innovation, and the artistry behind traditional methods, we uncover how maize milling not only fuels our bodies but also nourishes economies and sustains communities. Join us as we unravel the layers of this enduring staple and celebrate the craftsmanship that keeps the world turning one kernel at a time.

Understanding the Fundamentals of Maize Milling Process

The maize milling process is a fascinating blend of art and science, where the transformation of whole kernels into finely ground flour occurs through a series of systematic steps. Initially, the maize undergoes cleaning, which involves removing impurities such as stones, husks, and dirt to ensure a high-quality final product. Following this, the conditioning stage softens the maize seeds using controlled moisture, preparing them for milling. This critical step not only enhances the milling efficiency but also helps in achieving better flour quality. The next phase is the actual milling, where mechanical forces are applied to break down the grains into various particle sizes. The process may involve different milling systems, such as impact, abrasive, and shear, each contributing to the texture and consistency of the flour.

Once the maize is milled, it is essential to separate the various fractions obtained from the grinding process. This is where classification techniques come into play, aiding in segregating fine flour from coarser particles. The use of sifting and air classification allows mills to produce various grades of flour, catering to diverse culinary needs. A vital aspect of maize milling also lies in the moisture control and storage conditions of the final products, which significantly affect their shelf life and usability. To illustrate this, we can look into the components of a typical maize milling flowchart:

| Process Step | Description |

|---|---|

| Cleaning | Removal of impurities using screens and air blasts. |

| Conditioning | Moisture adjustment to prepare maize for milling. |

| Milling | Grinding the conditioned maize into flour using different methods. |

| Separation | Sifting and classifying the milled products into various grades. |

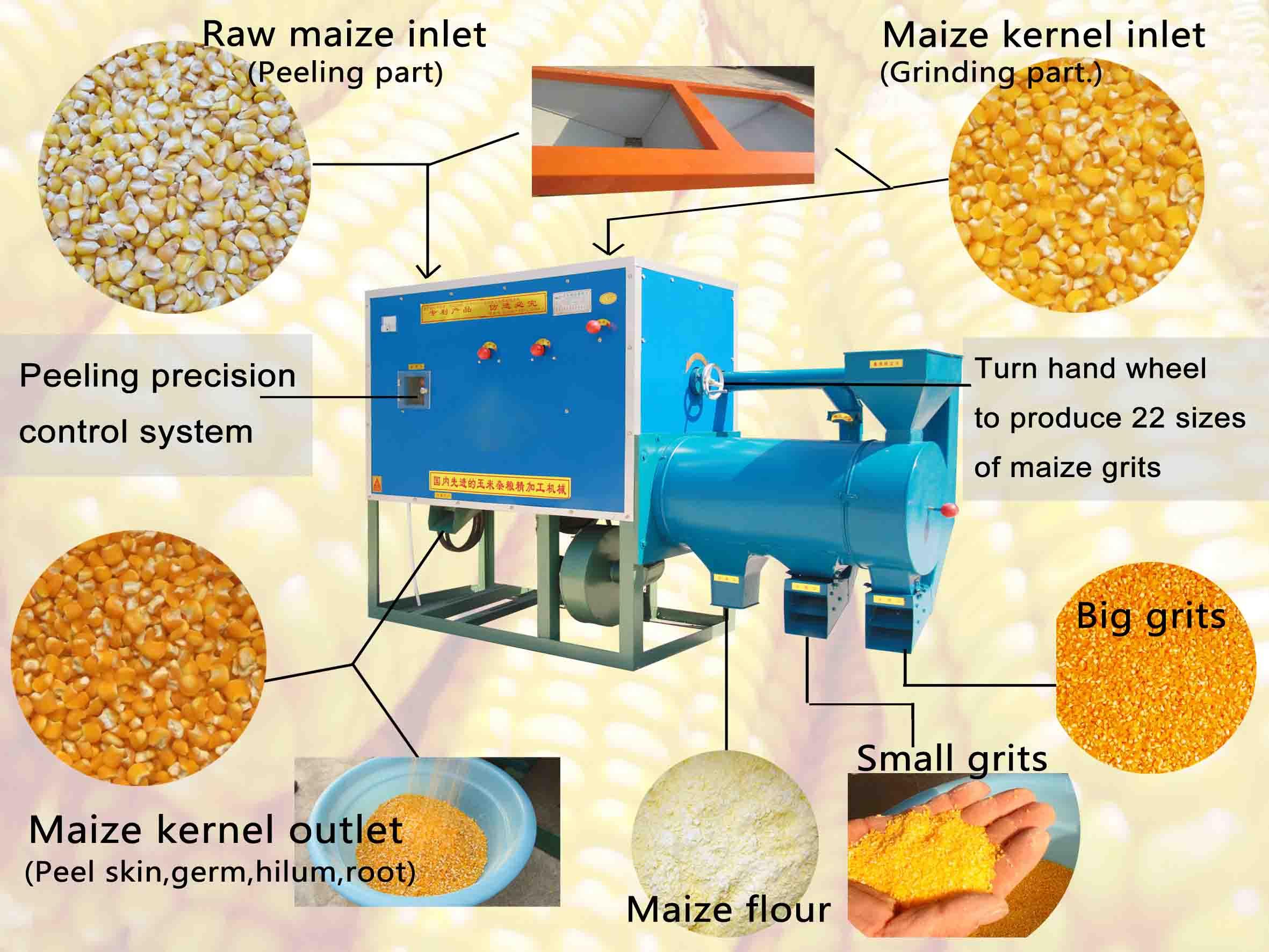

Exploring the Essential Equipment for Efficient Operations

To achieve optimal productivity in maize milling, possessing the right equipment is paramount. Modern milling operations rely on a carefully curated selection of machinery that streamlines the process from grain handling to packaging. Among the most vital components are:

- Milling Machines: These are the heart of the operation, available in various configurations such as hammer mills or roller mills, each suited for different milling requirements.

- Grain Elevators: Essential for moving the maize from one stage of processing to another, ensuring minimal spillage and ensuring operational efficiency.

- Dust Collectors: Integral for maintaining air quality and safety by managing the fine particles generated during milling.

- Pneumatic Conveyors: Utilizing air pressure to transport granular materials, they enhance speed and reduce physical handling.

In addition to these staple machines, supplementary equipment can significantly enhance the efficiency of the milling process. Consider incorporating:

- Quality Control Systems: Ensuring consistency in product performance and safety.

- Packaging Machines: Automating the packaging process to reduce labor and enhance production efficiency.

- Grain Cleaners: Essential for removing impurities and ensuring that only high-quality kernels are milled.

| Equipment Type | Function | Importance |

|---|---|---|

| Milling Machines | Grinding maize into flour | Core of the milling process |

| Grain Elevators | Transporting maize | Reduces manual handling |

| Dust Collectors | Air quality management | Enhances safety |

| Packaging Machines | Automating packaging | Increases efficiency |

Innovative Techniques for Enhancing Flour Quality

Modern milling techniques have emerged as a game-changer in the quest for superior flour quality. Leveraging advancements in technology, millers are now able to utilize precision grinding methods that optimize particle size and distribution. This transformation not only enhances the flour’s functional properties but also its nutritional profile. Some innovative techniques include:

- Ultrasonic Milling: This technique utilizes ultrasound waves to break down maize kernels, resulting in finer flour with reduced heat generation, which preserves vital nutrients.

- Hammer Mill Enhancements: By introducing variable speed controls and changing hammer patterns, this traditional method can achieve a more uniform grind and improved flour consistency.

- Air Classification: This method separates finer flour particles from coarser ones using air flow, ensuring a higher-quality product that meets specific baking requirements.

Additionally, the incorporation of digital monitoring systems has allowed for real-time adjustments during the milling process. This strategy ensures that parameters such as moisture content, temperature, and grinding time can be finely tuned to achieve optimal flour quality. Data analytics play a crucial role as well, helping millers to understand the characteristics of different maize varieties and tailor their processes accordingly. The evolving landscape of maize milling means we are continually moving towards a future where flour is not just a staple ingredient but a product of talent and technology.

| Technique | Benefit |

|---|---|

| Ultrasonic Milling | Finer flour with preserved nutrients |

| Hammer Mill Enhancements | Uniform grind and better consistency |

| Air Classification | Higher-quality flour tailored for baking |

Sustainability Practices in Maize Milling for Future Growth

In the quest for sustainable maize milling, industry practitioners are embracing innovative practices aimed at minimizing environmental impact while maximizing efficiency and product quality. One essential aspect of these sustainability initiatives is the incorporation of renewable energy sources, such as solar panels and biomass energy systems, which significantly reduce reliance on fossil fuels. This not only lowers operating costs but also contributes to a greener footprint. Additionally, the shift towards utilizing more efficient milling equipment ensures lower energy consumption, which is critical in scaling operations sustainably. Other practices that enhance sustainability include:

- Water Reuse: Implementing systems to reclaim and recycle water in the milling process.

- Waste Management: Using byproducts, such as maize husks and germ, for animal feed or bioenergy generation.

- Supplier Collaboration: Partnering with local farmers to source maize, reducing transportation emissions.

Moreover, careful consideration of production methods contributes to long-term sustainability goals. Organic practices are gaining traction; these focus on reducing chemical fertilizers and pesticides, fostering biodiversity, and promoting soil health. The embrace of precision agriculture technologies enables farmers to optimize input usage and reduces waste. Implementing these methods not only augments the resilience of the maize supply chain but also appeals to a growing demographic of environmentally conscious consumers. Key metrics to track progress in sustainability within maize milling include:

| Metrics | Current Value | Target Value |

|---|---|---|

| Energy Consumption (kWh/ton) | 120 | 90 |

| Water Usage (liters/ton) | 150 | 100 |

| Recycled Waste (% of total) | 30% | 50% |

The Way Forward

As we journey through the intricate world of maize milling, we’ve uncovered the blend of art and science that drives this vital industry. From the grinding of kernels to the emergence of flour, every stage reflects a dance between tradition and innovation. As we stand at the crossroads of agronomy and technology, the lessons learned from the milling process remind us of the resilience of those who cultivate and process this essential crop.

In a world where food security and sustainability increasingly dominate our conversations, understanding the intricacies of maize milling can inspire us to appreciate the journey our food takes from field to plate. Whether it’s the small artisanal mill in a rural community or the expansive facilities that power global markets, each contributes to a shared tapestry of culture and sustenance.

As we close this exploration, may we carry forward the insights gained, honoring the craft of milling while embracing the innovations that promise to shape its future. After all, in the simple act of grinding maize, we find not just a process but a profound connection to the past, present, and future of food.