In the heart of culinary traditions lies a timeless practice that bridges the gap between ancient methods and modern innovations: grain milling. Among the vast array of grains, maize holds a special place, celebrated not only for its versatility but also for the rich tapestry of flavors and textures it can impart to our dishes. “Grinding Grain: The Art and Science of Maize Milling” delves into this intricate process, exploring both the artistry involved and the scientific principles that underlie it. From the rhythmic sound of the millstone to the delicate adjustments of humidity and temperature, every aspect of maize milling reveals a fascinating interplay of tradition and technology. Join us as we uncover the history, techniques, and cultural significance of this essential practice, inviting you to appreciate the humble kernel in its journey from field to flour.

Understanding the Historical Significance of Maize Milling

Throughout history, maize has played a pivotal role in various cultures, shaping diets and economies across the globe. Its transformation from a humble grain to a dietary staple is accompanied by the art of milling, which has evolved over centuries. The earliest forms of maize milling involved rudimentary tools and hand-made grinding stones, which allowed ancient civilizations to unlock the grain’s potential. As technology advanced, so did the milling process, ultimately leading to the development of sophisticated machinery that significantly increased efficiency and flour quality. This evolution not only reflects the resourcefulness of different societies but also highlights how essential maize milling has been in promoting food security and economic stability.

The social and economic ramifications of maize milling extend beyond mere food production. In many communities, milling centers have served as hubs for cultural exchange and social interaction, fostering a sense of community among farmers and consumers. Additionally, the shift from traditional to modern milling techniques has influenced agricultural practices and market dynamics. As the demand for maize-based products grew, so too did investments in milling infrastructure, resulting in job creation and the empowerment of local economies. The historical journey of maize milling encapsulates a rich tapestry of innovation and community resilience, reminding us of the grain’s far-reaching influence on human civilization.

Exploring the Techniques: Traditional vs. Modern Grinding Methods

Grinding maize has evolved significantly over the centuries, with traditional methods often being steeped in cultural significance. Traditional techniques include the use of hand-operated stone mills and wooden mortars, which are often crafted by local artisans and passed down through generations. These methods allow for a tactile connection to the grain, as the grinder can feel the texture and adjust the pressure accordingly. The process requires patience and skill, resulting in a unique flavor profile that reflects the nuances of locally sourced maize. Moreover, the rhythmic sounds of the grinding resonate deeply with community traditions, creating a sense of belonging and a celebration of heritage.

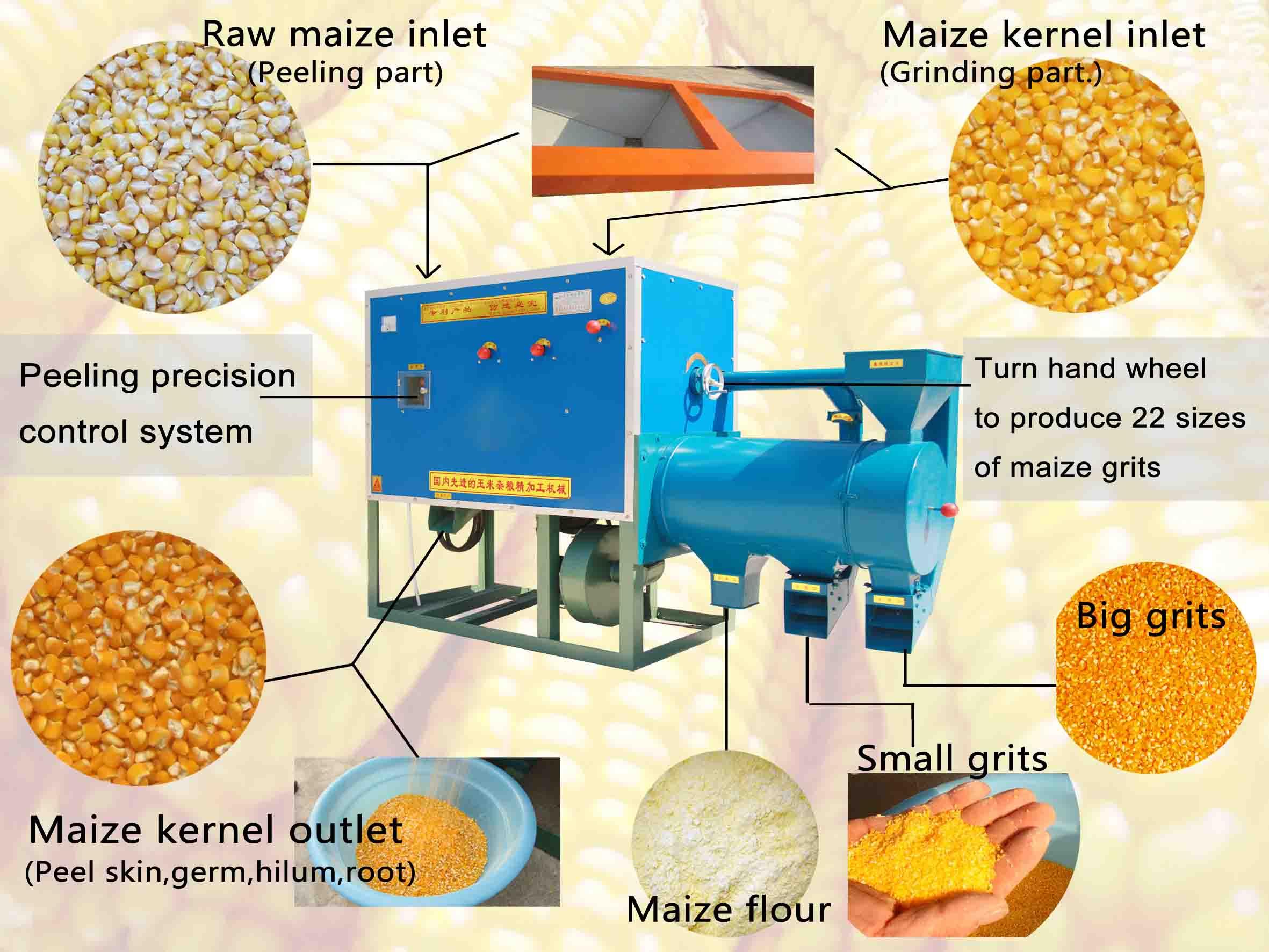

In contrast, modern grinding methods leverage advanced technology to enhance efficiency and consistency. Industrial milling machines incorporate steel roller mills and hammer mills, streamlining the grinding process for large-scale production. These innovations ensure that maize is ground uniformly, minimizing waste and maximizing yield. Furthermore, automation and digital monitoring provide precise control over the milling conditions, allowing for adjustments in real-time. The use of modern techniques has revolutionized the industry, enabling broader access to finely milled products while maintaining a commitment to quality. The amalgamation of tradition and technology encapsulates the journey of maize from field to flour, highlighting how progress can harmonize with cultural practices.

| Grinding Method | Advantages | Disadvantages |

|---|---|---|

| Traditional Grinding |

|

|

| Modern Grinding |

|

|

Assessing Flour Quality: Key Factors in Maize Milling

When it comes to maize milling, the quality of flour produced is intimately tied to various factors that influence the grinding process. One of the primary elements in assessing flour quality is the moisture content of the grains, which ideally should fall between 13% and 15%. Higher moisture levels can lead to spoilage and reduced shelf life, while lower levels may result in insufficient extraction during milling. Additionally, the kernel hardness plays a significant role; harder kernels yield finer flour but require more energy during milling. The balance of these factors affects not only the texture and flavor of the final product but also the efficiency of the milling operation itself.

Furthermore, the variety of maize used is crucial to attaining optimal flour quality. Different maize varieties can vary significantly in attributes like starch content, protein levels, and oleic acid composition, all of which influence the functionality of the flour in various applications. It’s essential to conduct a comprehensive evaluation that includes:

- Granulation: The particle size distribution of flour affects the baking properties.

- Color: Visually appealing flour can enhance product attractiveness.

- Aroma: Freshly milled maize flour has a distinctive scent that indicates quality.

To summarize these elements, a well-defined quality assessment can be represented in the following table:

| Factor | Ideal Range | Impact on Quality |

|---|---|---|

| Moisture Content | 13% – 15% | Shelf Life, Milling Efficiency |

| Kernel Hardness | Medium to Hard | Grinding Energy, Flour Texture |

| Variety of Maize | Naturally Varies | Flavor, Nutritional Value |

Sustainability in Grain Processing: Best Practices for Eco-Friendly Milling

In the quest for eco-friendly milling, several best practices can be implemented to ensure grain processing aligns with sustainability principles. First and foremost, utilizing energy-efficient machinery is paramount. Upgrading to high-efficiency mills can significantly reduce energy consumption while maintaining productivity. Additionally, adopting renewable energy sources, such as solar or wind, can further minimize the carbon footprint of the milling process. Emphasizing water conservation techniques during processing is also crucial, with options like recycling water used in various stages and implementing closed-loop systems to maximize resource use.

Another significant aspect is reducing waste throughout the milling process. Implementing efficient by-product management strategies ensures that every part of the grain is utilized. This includes producing animal feeds, biomass, or even fermentable products from leftover materials. Incorporating eco-friendly packaging solutions is also essential, as many milling operations can significantly impact environmental health through packaging waste. Moreover, establishing partnerships with local farmers can strengthen community ties and promote sustainable agricultural practices, creating a synergistic relationship that prioritizes environmental stewardship.

In Retrospect

In closing, the intricate dance of grinding grain, particularly maize milling, is a practice that marries tradition with innovation. Whether in the humble kitchen or the expansive industrial mill, the transformation of maize into flour is not merely a process but a testament to human ingenuity and cultural heritage. As we’ve explored, the techniques involved—from the ancient methods passed down through generations to the cutting-edge technology shaping today’s milling industry—reflect a deep connection to our past while propelling us into the future.

Understanding the art and science behind maize milling enhances our appreciation for the food we consume and the stories woven into each grain. As you venture into your next culinary endeavor, consider the journey of the maize that has traveled from field to mill, and ultimately, to your table. Each kernel carries with it the weight of history, economy, and sustenance, embodying the resilience and creativity of countless communities worldwide. So, next time you enjoy a dish made with freshly milled maize, remember the beauty of that grinding process—a blend of artistry and precision that continues to nourish our lives.