Grains to Greatness: The Art of Cereal Milling Unveiled

In a world fueled by the relentless pace of modern life, where convenience often trumps tradition, the humble grain remains a steadfast pillar of our dietary foundation. But have you ever paused to consider the journey these grains undertake before they reach your breakfast table? “Grains to Greatness: The Art of Cereal Milling Unveiled” invites you to explore the intricate and often overlooked craft of cereal milling—a process that transforms raw grains into the nourishing staples we rely on daily. From the golden fields where wheat and oats sway gently in the breeze to the whirring machinery of the mill that meticulously prepares them, we will delve into the artistry, science, and tradition behind this age-old practice. Join us as we uncover the secrets of cereal milling, revealing not just the techniques that bring out the best in our grains, but also the stories, cultures, and innovations that shape a beloved food industry.

Exploring the Journey from Grain to Flour: Techniques and Innovations

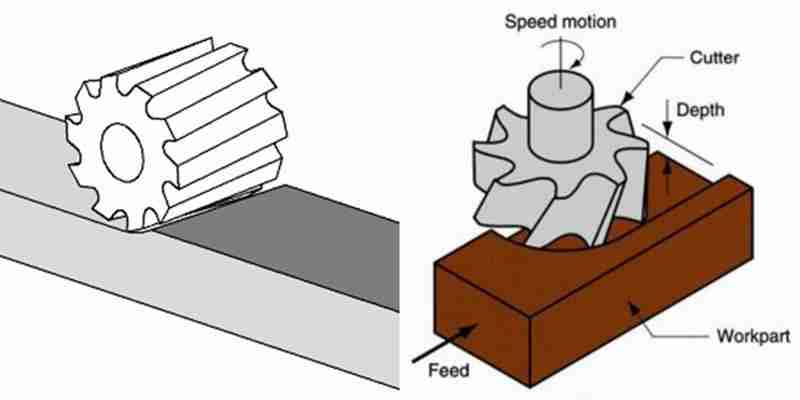

The transformation of grain into flour is a fascinating journey steeped in tradition and modern innovation. At the heart of this process is the milling technique, which has evolved significantly from ancient hand grinding methods to sophisticated machinery that enhances efficiency and consistency. Traditional stone milling, characterized by its gentle grinding action, preserves the grain’s nutritional value and flavor. In contrast, modern roller milling employs a series of steel rollers to refine grains into flour, allowing for higher extraction rates and finer textures. Each technique brings a unique character to the final product, impacting everything from the taste of baked goods to their nutritional profile.

As we continue to explore the intersection of technology and craftsmanship, several innovations are emerging in the milling industry. For instance, air classification separates flour particles by size, resulting in a more uniform product. Additionally, the adoption of digital milling technologies leverages artificial intelligence to optimize grain processing, enhancing quality control and reducing waste. Other advancements include sustainability practices that incorporate energy-efficient machinery and the use of alternative grains, pushing the boundaries of traditional milling. These developments not only improve production capabilities but also allow consumers to enjoy a wider variety of flour types, reshaping how we engage with this ancient staple.

| Technique | Key Features | Benefits |

|---|---|---|

| Stone Milling | Gentle grinding, retains nutrients | Rich flavor, diverse textures |

| Roller Milling | High efficiency, fine texture | Cost-effective, consistent quality |

| Air Classification | Size separation of flour particles | Uniform product, better baking results |

| Digital Milling | AI optimization, automated processes | Quality control, reduced waste |

Understanding Milling Processes: Traditional vs. Modern Approaches

The landscape of milling has experienced a remarkable transformation over the years, evolving from traditional methods reliant on manual labor and simple machines to modern, automated processes that enhance efficiency and precision. In traditional milling, the interaction of stone against stone or manual grinding resulted in a rustic flour texture, capturing the essence of the grain while requiring significant physical effort. The process can be characterized by its simplicity and authenticity, often leading to unique flavor profiles created by the miller’s touch. Today, the artistry of older techniques is celebrated not just for its nostalgia but for the specific qualities it imparts to the final product. Modern milling, however, embraces technology, utilizing advanced machinery that offers a plethora of benefits.

Modern milling techniques are built on the foundation of automation, ensuring consistency and speed, but they may sometimes overlook the nuances that give flour its distinctive character. Key features of contemporary milling include:

- Precision: Advanced technology allows for exact control over grinding settings.

- Speed: High-capacity machinery can produce large quantities in record time.

- Versatility: State-of-the-art systems can accommodate various grains and blends.

While the chasm between these two approaches appears daunting, a balance between tradition and modernity is increasingly sought after. Millers today often integrate elements of both worlds, resulting in a new wave of milling practices that honor the past while addressing contemporary demands. This hybrid approach enables a refined selection process, bringing to the market products that appeal to both artisanal connoisseurs and industrial standards.

| Aspect | Traditional Milling | Modern Milling |

|---|---|---|

| Process | Manual labor, stone milling | Automated machinery |

| Texture | Rustic, varied | Consistent, specific |

| Flavor | Unique and complex | Standardized, versatile |

| Production Time | Slow | Rapid |

Enhancing Nutritional Value: The Role of Whole Grains in Cereal Production

Whole grains have emerged as the unsung heroes in the quest for enhanced nutritional value within cereal production. As the foundation of a balanced diet, they offer an impressive array of nutrients, including fiber, vitamins, and minerals. The transformation of these grains during the milling process is crucial, as it enhances their digestibility and versatility. This process preserves the bran and germ, ensuring that the final product remains rich in essential nutrients and health benefits. It’s not just about grinding grains; it’s about creating a nourishing experience for consumers who increasingly seek wholesome, nutritious options.

The benefits of incorporating whole grains into cereal production go beyond individual health; they also contribute to sustainability and agricultural diversity. By utilizing a variety of whole grains, producers can support biodiversity while also appealing to a broader audience. Consider the following advantages of whole grain cereals:

- High Fiber Content: Promotes digestive health and aids in weight management.

- Rich in Antioxidants: Helps combat oxidative stress and reduce inflammation.

- Lower Glycemic Index: Supports stable blood sugar levels, making them suitable for a range of diets.

- Versatile Flavor Profiles: Offers unique tastes that can enhance the overall sensory experience of cereals.

To visualize the impact of whole grains in cereal production, consider the nutrient breakdown of popular grain types typically used in milling:

| Grain Type | Fiber (g per 100g) | Protein (g per 100g) | Key Nutrients |

|---|---|---|---|

| Oats | 10.6 | 12.5 | B Vitamins, Iron |

| Quinoa | 2.8 | 4.1 | Magnesium, Zinc |

| Brown Rice | 3.5 | 2.6 | Selenium, Manganese |

| Barley | 17.3 | 12.5 | Iron, Phosphorus |

By showcasing the nutritional advantages of whole grains, cereal producers can craft products that not only meet consumer demands but also contribute to improved public health outcomes. The journey from grain to breakfast bowl is not merely an industrial process; it is an art form that, when executed with attention to whole grain qualities, can lead to both greatness on the table and benefits to society as a whole.

Sustainability in Milling: Best Practices for a Greener Future

In the pursuit of a greener future, the milling industry is making significant strides towards sustainability by adopting innovative practices. By leveraging renewable energy sources such as solar and wind power, mills can reduce their carbon footprint while maintaining efficient production levels. Additionally, implementing state-of-the-art technologies, like energy-efficient machinery and real-time monitoring systems, helps in optimizing resource use, which can drastically lower energy consumption and emissions. Other best practices include:

- Waste Minimization: Employing methods that reduce waste during the milling process, such as utilizing by-products in the production of animal feed or biofuels.

- Sustainable Sourcing: Partnering with local farmers to source grains that are grown using environmentally friendly practices.

- Water Conservation: Adopting closed-loop systems for water reuse in the milling process, limiting water usage and protecting local water resources.

Moreover, mills are increasingly aware of the importance of responsible packaging and distribution. By utilizing biodegradable and recyclable materials, they can contribute to less landfill waste. Investing in digital solutions enhances transparency in their supply chains, allowing consumers to make informed choices. This commitment to sustainability is further exemplified through collaborative initiatives that bring together stakeholders within the industry, promoting an eco-friendly approach that encompasses:

| Initiative | Description |

|---|---|

| Resource Sharing | Pooling resources among mills to share best practices for sustainable operations. |

| Community Engagement | Involving local communities in sustainability efforts through education and participation. |

| Certification Programs | Obtaining certifications that recognize commitment to sustainability, enhancing marketability. |

Future Outlook

As we conclude our journey through the intricate world of cereal milling, it becomes clear that this age-old craft is far more than mere grains being ground into flour. It is a harmonious blend of tradition, science, and artistry that transforms humble kernels into the foundation of our daily sustenance. From the rhythmic hum of the millstone to the meticulous selection of grains, every step in the process reflects a dedication to quality and innovation.

Understanding the art of cereal milling not only enriches our appreciation for the foods we consume but also highlights the essential role these processes play in global agriculture and culinary culture. As we savor our morning bowls or bake with that freshly milled flour, we can celebrate the intricate journey from fields to tables, where grains indeed pave the way to greatness.

So next time you pour that cereal, remember: you’re partaking in a legacy that marries the past with the present, a craft that continues to evolve while remaining grounded in its rich heritage. As we move forward, may the art of milling inspire a deeper connection to the food that nourishes our lives.