Grains to Greatness: The Art and Science of Cereal Milling

In the world of food production, the journey from farm to table is often a tale of transformation, where simple ingredients are elevated to culinary staples through generations of knowledge and innovation. At the heart of this process lies cereal milling – an age-old craft that has evolved into a sophisticated blend of art and science. From the rhythmic grinding of grain to the precise measurements that ensure quality and consistency, the milling process has a profound impact on the textures, flavors, and nutritional profiles of the foods we cherish.

As we delve into the mechanics of cereal milling, we uncover not just the machinery and techniques that drive this industry but also the rich traditions and advancements that have shaped it over time. This exploration takes us through the history of grains, the nuances of milling methods, and the vital role of technology in enhancing efficiency and sustainability. Join us on this enlightening journey as we unravel the complexities of cereal milling, revealing how it transforms humble grains into foundational elements of our diets while celebrating the artistry that lies within this essential craft.

Understanding the Unique Properties of Grains in Cereal Milling

The journey from grain to flour is a marvel of nature and science, heavily reliant on the distinctive properties of various grains. Each grain possesses unique characteristics that influence its behavior during the milling process. For instance, hard wheat is known for its high protein content, which contributes to the strength and elasticity of dough, making it a preferred choice for bread-making. Conversely, soft wheat has a lower protein count, rendering it ideal for cakes and pastries where tenderness is paramount. Additionally, grains like barley and rye bring their own textures and flavors, enriching our baked goods and cereals with diversity and nutrition.

The physical attributes of grains also play a crucial role in determining the milling technique employed. For instance, kernel hardness affects the type of milling equipment and processes utilized. The size and shape of the grain influence how well it can be crushed or ground. The following factors are essential in understanding how grains behave during milling:

- Moisture Content: Impacts the milling efficiency and flour yield.

- Test Weight: Indicates the density and quality of the grain.

- Gluten Quality: Dictates the elasticity and extensibility of the dough.

- Color: Affects consumer preference and marketability.

| Grain Type | Milling Properties | Common Uses |

|---|---|---|

| Hard Wheat | High protein, strong gluten | Breads, pasta |

| Soft Wheat | Low protein, weak gluten | Cakes, cookies |

| Barley | High fiber, low starch | Soups, brewing |

| Rye | High water absorption | Rye bread, crackers |

The Milling Process: Techniques that Transform Grains into Flour

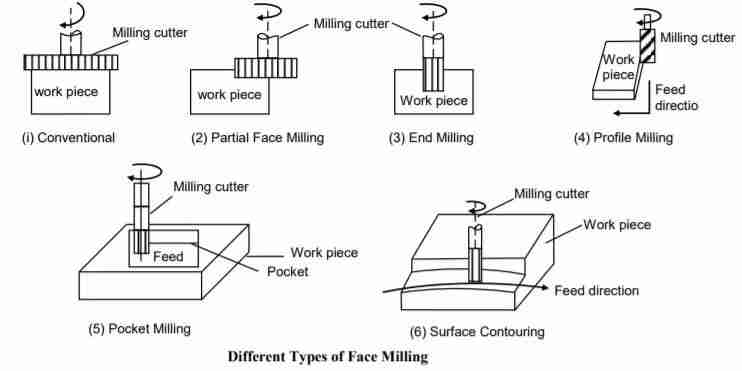

The transformation of whole grains into flour is a meticulous dance between art and science, encompassing various techniques that enhance both texture and flavor. At the heart of this milling process lies the initial cleaning of grains, ensuring all foreign materials are thoroughly removed. Following this, conditioning occurs, which involves hydrating the grain slightly to facilitate more efficient milling. Subsequently, the actual milling can take shape through diverse methods, each offering distinct characteristics to the final flour. Some of the key techniques employed include:

- Hammer Milling: Employs high-speed rotation to crush grains into finer particles.

- Stone Milling: Utilizes stones to grind grains, preserving nutrients and creating a coarser texture.

- Roller Milling: Involves a series of rollers that compress and shear the grain for an ultra-fine flour.

After the grains undergo milling, the flour is graded based on its quality and particle size, which can significantly influence its culinary applications. A table elucidating the types of flour produced through different milling techniques highlights not only their textures but also their typical usages in baking and cooking:

| Milling Technique | Flour Type | Common Uses |

|---|---|---|

| Hammer Milling | Whole Wheat Flour | Breads, Pancakes |

| Stone Milling | Artisan Flour | Breads, Crackers |

| Roller Milling | All-Purpose Flour | Cakes, Pastries |

Each milling technique contributes uniquely to the flour’s flavor, nutritional content, and baking properties, showcasing the intricate balance between technology and tradition in grain processing. Rather than merely functional, this process is a celebration of the natural diversity found in grains, allowing bakers to select a flour type that best suits their culinary ambitions.

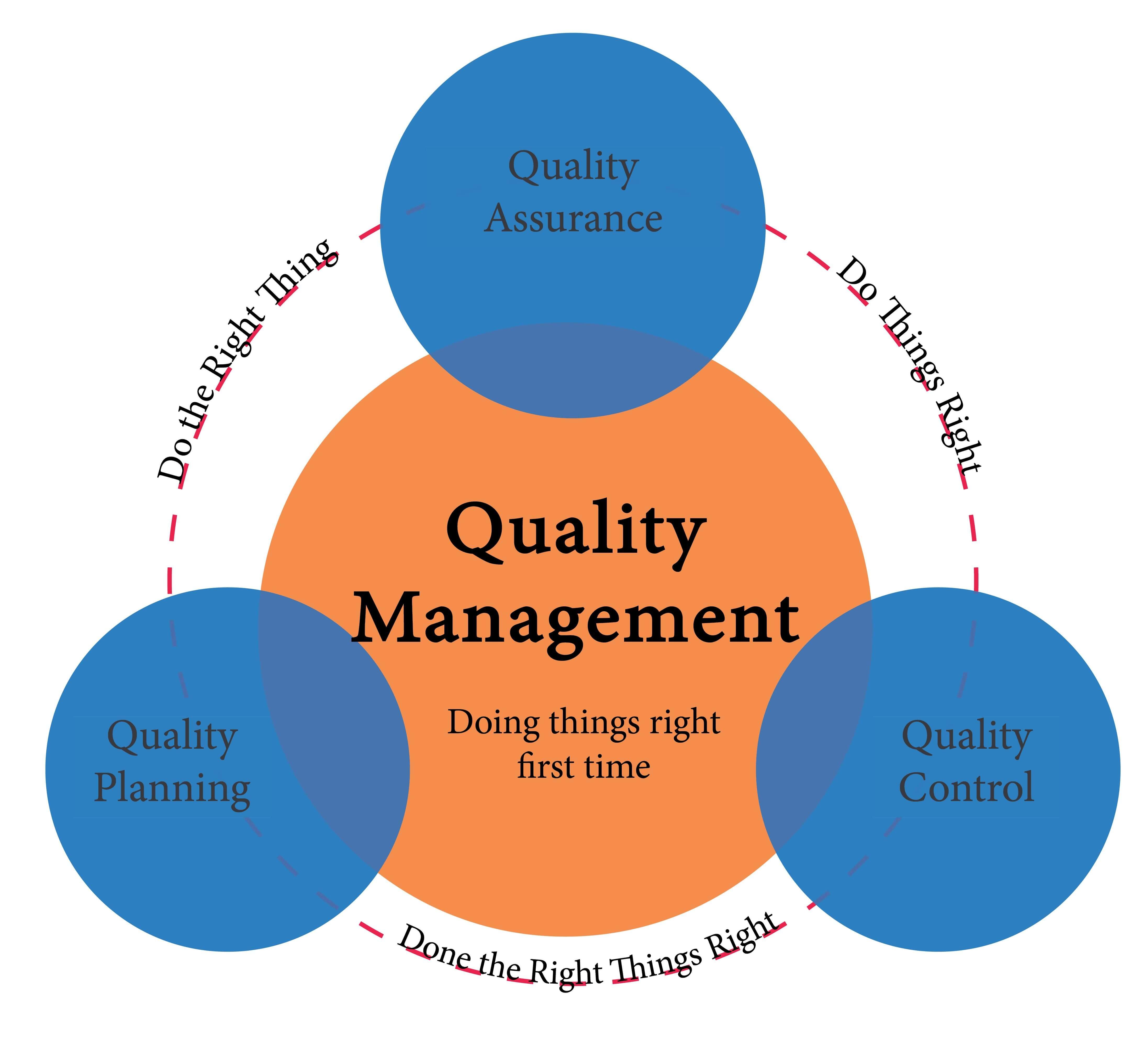

Quality Control in Cereal Production: Ensuring Consistency and Safety

In the world of cereal production, quality control serves as the backbone of the entire process, ensuring that every batch meets consumer expectations for consistency and safety. As grains transition from their raw state to finely milled products, a series of rigorous tests and evaluations come into play. Techniques applied in quality control are multifaceted, focusing on both the physical and chemical properties of the grains. Regular assessments include:

- Moisture Content Analysis: Critical for preventing spoilage and ensuring shelf stability.

- Grain Texture and Size Distribution: Affecting the milling process and, ultimately, the final product quality.

- Contaminant Screening: Vital for identifying pathogens, mycotoxins, or foreign materials that could compromise safety.

Advanced technologies, such as near-infrared spectroscopy (NIR) and computerized imaging systems, enhance the precision of these evaluations. These methods not only save time but also improve accuracy, creating a robust framework for decision-making in milling operations. To exemplify the significance of quality control processes, the following table highlights some key quality indicators alongside their acceptable ranges:

| Quality Indicator | Acceptable Range |

|---|---|

| Moisture Content | 12-14% |

| Protein Level | 10-12% |

| Falling Number | 200-300s |

| Wheat Kernel Hardness | 50-80% Hard |

Effective quality control not only safeguards against inconsistencies that could lead to product recalls but also builds consumer trust in the product. For cereal manufacturers, maintaining stringent quality protocols is essential for achieving the desired balance between cost-efficiency and exceptional product standards. By prioritizing these measures, mills can ensure their products are both reliable and safe for the market.

Innovative Trends: The Future of Cereal Milling and Sustainable Practices

As the cereal milling industry evolves, innovative technologies are paving the way for sustainable practices that promise to redefine the field. Smart milling technologies are emerging that optimize energy consumption, minimize waste, and enhance product quality. For instance, the integration of artificial intelligence into milling processes allows for real-time adjustments based on grain characteristics, leading to more efficient resource use. Additionally, advancements in biomass energy generation enable mills to convert by-products into renewable energy, thus creating a closed-loop system that reduces carbon footprints and encourages eco-friendly operations.

Beyond technology, the shift towards sustainable sourcing of raw materials is also gaining momentum. Millers are increasingly collaborating with local farmers who practice regenerative agriculture, which focuses on soil health and biodiversity. The trend encourages a transparent supply chain where the story behind each grain is told, enriching customer experience. Notably, the following elements are becoming mainstream in these sustainable efforts:

- Use of organic grains to cater to health-conscious consumers.

- Water conservation techniques during milling operations.

- Eco-friendly packaging to reduce waste in the consumer market.

| Trend | Impact |

|---|---|

| Smart Milling Technologies | Higher efficiency and lower waste |

| Local Sourcing | Supports local economies and reduces transport emissions |

| Eco-friendly Packaging | Less plastic waste contributing to sustainability |

Final Thoughts

As we conclude our exploration of “Grains to Greatness: The Art and Science of Cereal Milling,” we’ve uncovered the intricate layers of a process that is both an age-old craft and a marvel of modern engineering. From the humble fields of golden wheat to the bustling mills where grains undergo their transformative journey, cereal milling embodies the delicate balance between tradition and innovation.

Each grain tells a story shaped by countless hands, relentless creativity, and the pursuit of perfection. While technology continues to advance, enabling precision and efficiency, the timeless skills of millers remain at the heart of this age-old art. As we savor the fruits of these efforts—be it in a steaming bowl of oatmeal or freshly baked bread—let us not forget the unseen labor and science that have brought these treasures to our tables.

In celebrating the journey from grains to greatness, we invite you to appreciate not just the final product, but the rich tapestry of knowledge, dedication, and passion woven into every grain. May this newfound understanding inspire a deeper connection to the foods we cherish and the artistry of those who craft them. Until our next culinary exploration, may your grains always lead to greatness!