In the heart of culinary tradition lies a humble yet transformative journey, one that begins with a single grain of maize and culminates in the powdery finesse of flour. This artful process, often overlooked, is a fusion of time-honored techniques and modern technology, illustrating how a staple crop can be meticulously transformed into a versatile ingredient that graces countless recipes around the globe. From the golden ears of corn harvested under sun-drenched fields to the rhythmic hum of milling machines grinding kernels into fine flour, the maize milling process is a testament to both nature’s bounty and human ingenuity. In this exploration, we will delve into the intricate steps that breathe life into maize, unearthing the profound connection between agricultural practice and culinary creativity. Join us as we unravel the story “From Grain to Flour,” and celebrate the artistry behind one of the world’s most beloved staple foods.

Understanding the Fundamentals of Maize Milling Techniques

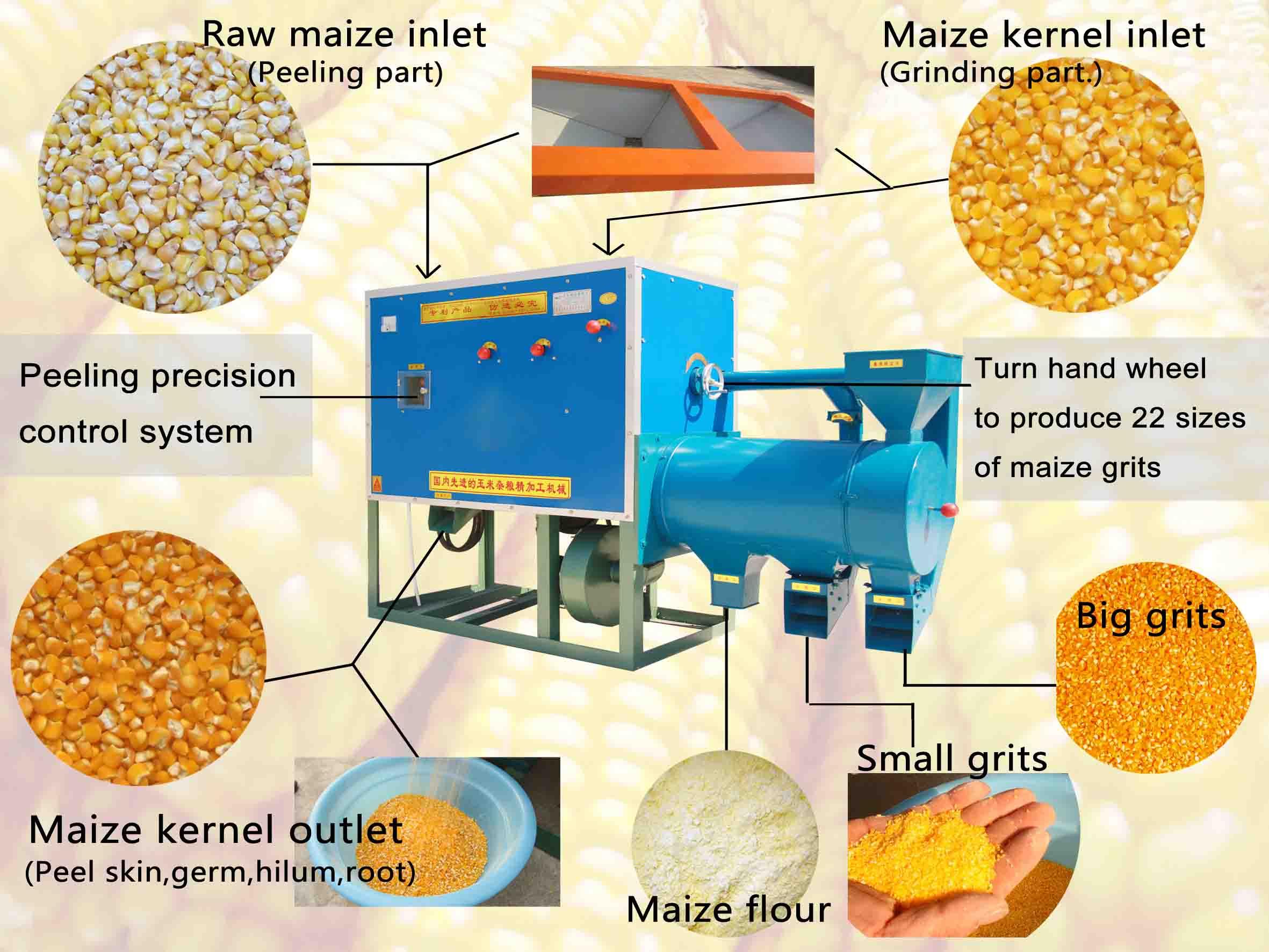

The maize milling process is an intricate dance of techniques that transforms raw maize into fine flour, ready to nourish countless meals worldwide. At the heart of this process lies a series of steps that emphasize precision, efficiency, and quality control. First, the grains are thoroughly cleaned to remove impurities, including dust, husks, and stones. This initial step ensures that only the highest-quality maize is used for milling. Next, the grains undergo condition hydration where controlled moisture is added to facilitate the milling process. This step prepares the kernels for optimal separation during the milling phase, thus preserving valuable nutrients and enhancing the texture of the flour.

The milling itself can be achieved through various methods, ensuring that each end product meets specific culinary needs. Common techniques include dry milling and wet milling. Dry milling involves grinding the maize kernels into flour without adding water, resulting in a finer product more suitable for baking and cooking. On the other hand, wet milling focuses on soaking the maize to enhance the extraction of starches and proteins, making it ideal for producing products like tortillas and snacks. Below is a brief overview of these methods:

| Milling Method | Description | Best Use |

|---|---|---|

| Dry Milling | Grinding kernels into flour without adding moisture. | Baking, Cooking |

| Wet Milling | Soaking maize for better starch and protein extraction. | Tortillas, Snacks |

Ultimately, understanding these foundational aspects of maize milling allows producers to tailor their processes to meet both consumer demands and industry standards. Each technique brings forth distinct qualities that not only contribute to the milling efficiency but also impact the nutritional profile and culinary applications of the resulting flour, enriching our diets with a versatile staple.

The Journey of Maize: From Harvesting to Preparation

The journey of maize begins in the golden fields, where farmers meticulously monitor the crops until the time arrives for harvesting. Once the ears of corn reach their peak ripeness, they are skillfully plucked, taking care to select only the best specimens. After harvesting, the maize undergoes a crucial process of drying and curing, which involves removing excess moisture to prevent spoilage. This preparatory stage lays the groundwork for what is to come. Once dried, the maize is transported to milling facilities, where it is cleaned and inspected, ensuring that only the highest quality grains proceed further.

In the milling process, the dried maize is transformed into various products through a series of specialized techniques. Milling involves grinding the grains into flour, a process that can yield several types depending on the desired outcome. Key steps in this transformation include:

- Cleaning: Removing any impurities and foreign particles.

- Grinding: Breaking down the grains into flour using different types of mills.

- Sifting: Separating the fine flour from the coarser material, ensuring a uniform texture.

These meticulous stages are essential to produce high-quality maize flour, which is then used in a variety of culinary applications. To illustrate, the table below summarizes some common types of maize flour derived from this intricate process:

| Type of Flour | Description |

|---|---|

| Fine Cornmeal | Ideal for baking, pancakes, and cornbread. |

| Coarse Cornmeal | Perfect for polenta and thicker textures in recipes. |

| Nixtamalized Flour | Used in traditional tortillas for enhanced flavor and nutrition. |

Optimizing the Milling Process for Quality Flour Production

To ensure the highest quality flour production, optimizing the milling process is crucial. Factors such as grain selection, moisture content, and milling techniques play pivotal roles in determining the final product’s quality. Choosing the right maize variety is essential, as it must have the perfect balance of starch and protein to yield flour with desirable baking characteristics. Furthermore, maintaining an optimal moisture content—typically between 13-14%—is vital for achieving the desired texture and preventing spoilage during storage.

In the milling stage, employing modern machinery and techniques can significantly enhance the quality of flour. Utilizing multiple passes through different milling systems allows for precision in both size reduction and separation of bran and germ from the endosperm. Some of the key methods include:

- Hammer milling: Ideal for coarse grinding, providing a versatile approach.

- Roller milling: Offers fine flour production with consistent particle size.

- Stone milling: Preserves the grain’s natural flavors and nutrients.

In managing these processes, a systematic approach to quality control is essential. This can be achieved by regularly testing flour for parameters such as protein content, granulation, and color. Below is a simple table showcasing key quality parameters often monitored during the milling process:

| Parameter | Ideal Range |

|---|---|

| Moisture Content | 13-14% |

| Protein Content | 8-10% |

| Ash Content | 0.4-0.6% |

Exploring Sustainable Practices in Maize Flour Milling

In the quest for more sustainable practices within maize flour milling, several innovative approaches are gaining traction. By integrating eco-friendly technologies and methodologies, millers can significantly reduce their carbon footprint while enhancing product quality. Among the most effective measures are:

- Energy-efficient machinery: Utilizing equipment that consumes less energy leads to lower operational costs and decreased environmental impact.

- Waste valorization: By-products from the milling process, such as husks and germ, are increasingly repurposed for animal feed or biogas production.

- Water conservation techniques: Implementing systems to recycle and treat water minimizes the consumption of this precious resource during the milling process.

Additionally, adopting organic farming methods for maize cultivation contributes to the sustainability of flour milling. By sourcing grains from local farmers who prioritize organic techniques, mills can ensure that their inputs are free from harmful pesticides and fertilizers. This not only supports local economies but also minimizes the environmental impact associated with long-distance transportation. To illustrate the balance between sustainability and operational efficiency, consider the following table:

| Practice | Benefit |

|---|---|

| Energy-efficient machinery | Reduces energy costs |

| Waste valorization | Diversifies revenue streams |

| Water conservation | Minimizes resource use |

| Organic sourcing | Promotes healthier products |

Insights and Conclusions

the journey from grain to flour is a fascinating odyssey that transforms humble maize into a versatile ingredient cherished by cultures around the globe. Each step of the milling process—steeped in tradition and innovation—plays a crucial role in unlocking the full potential of this nutrient-rich crop. From selecting the finest kernels to the rhythmic cadence of grinding, the artistry of maize milling not only preserves age-old practices but also adapts to modern demands, mirroring the evolution of culinary creativity. As we stand at the intersection of heritage and progress, we appreciate how this ancient craft continues to feed our bodies and inspire our kitchens, ensuring that the story of maize flour remains woven into the fabric of our daily lives. Whether used to craft a hearty tortilla or a delicate pastry, the end product is a testament to the intricate journey it undertook—a journey that invites us to savor every bite.