In the heart of every loaf of bread, pancake stack, or bowl of cereal lies a transformative journey—one that begins with humble grains and culminates in the fine powders that form the foundation of countless meals. “From Grain to Flour: The Art of Cereal Milling Unveiled” invites readers into the intricate world of cereal milling, a process that seamlessly blends tradition with innovation. As we explore the ancient techniques and modern machinery that have shaped this vital craft, we will uncover the science, artistry, and cultural significance of transforming raw grains into the versatile flour that nourishes us. Join us as we delve into the rich tapestry of cereal milling, revealing not only how our staple ingredients are produced but also the stories and traditions that have flourished alongside them throughout the ages.

The Journey of Grains: Understanding Different Varieties and Their Roles

Understanding the journey of grains begins with acknowledging the diverse varieties cultivated across the globe. Each type of grain boasts unique characteristics that influence not just their taste but also their nutritional profile and utility in various culinary applications. Wheat, rice, corn, and oats stand out as staple grains, yet their classifications are further nuanced. For instance, wheat can be categorized into hard and soft varieties, impacting its suitability for bread-making or pastries, while rice extends from long-grain basmati to the short-grain sushi types. The role of each grain extends beyond mere sustenance; it intertwines with cultural practices, regional cuisines, and even agricultural sustainability efforts.

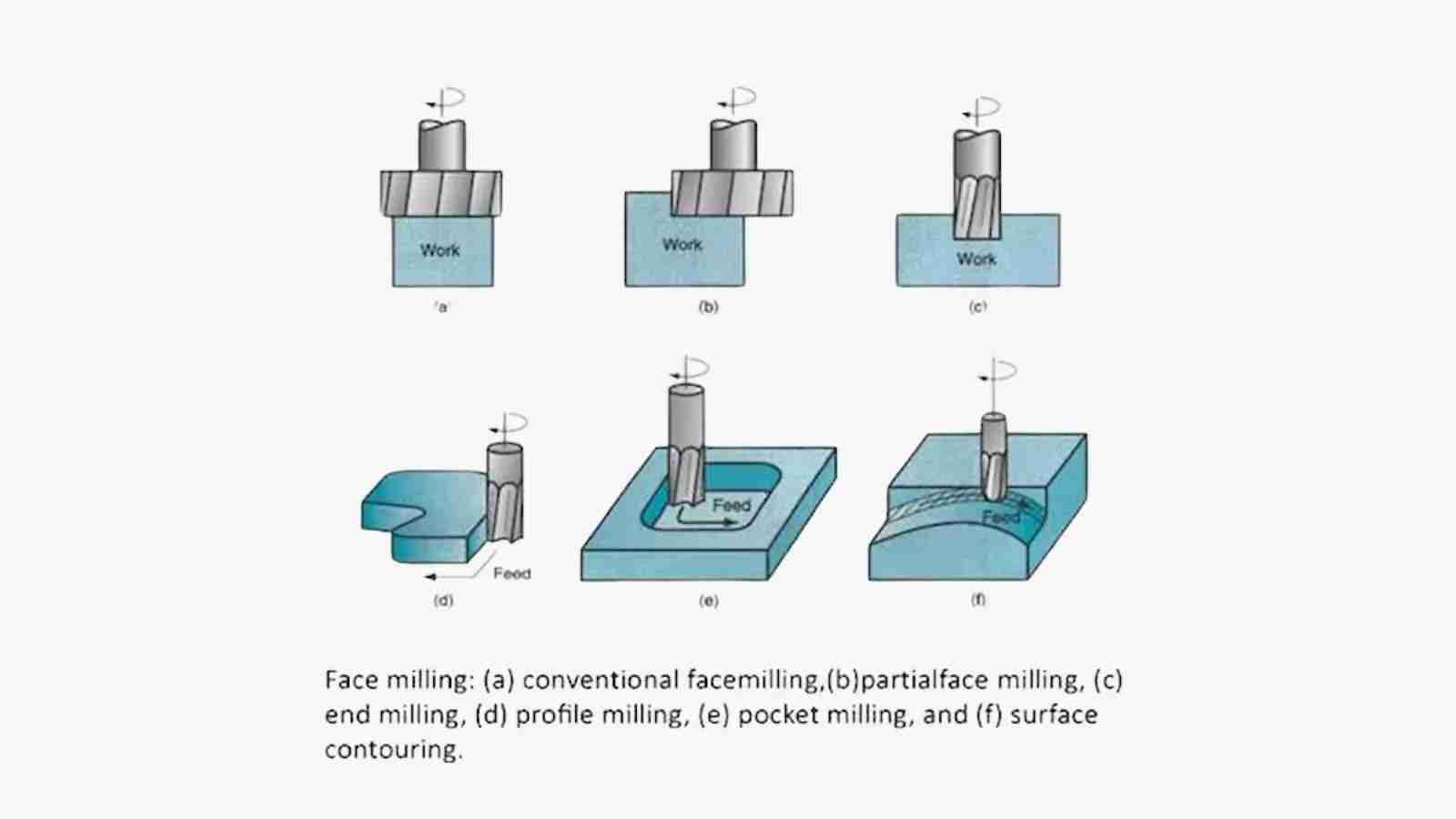

The process of transforming these grains into flour showcases both tradition and innovation in cereal milling. Understanding milling techniques is paramount for recognizing how the grain’s integrity is preserved or altered. Common methods include stone milling, roller milling, and hammer milling, each producing flour with distinct textures and flavors. To illustrate the distinctions in milling methods and their effects on flour quality, consider the following table:

| Milling Method | Description | Ideal For |

|---|---|---|

| Stone Milling | Traditional method using large stones to grind grains. | Artisan breads, whole grain flours |

| Roller Milling | Modern and efficient; uses rollers to crack and refine grains. | All-purpose flours, commercial baking |

| Hammer Milling | Uses high-speed rotating hammers to pulverize grains. | Animal feed, coarse flour |

As grains undergo milling, their transformation into flour not only reflects mechanical processes but also the intricate dance between nature and human ingenuity. The end product serves as a canvas for culinary creativity, allowing chefs and home bakers alike to explore textures and flavors that have evolved through generations. Each method carries a story; one woven into the very fabric of our diets and culinary traditions, thus shedding light on the indispensable role of grains in food production.

Uncovering the Milling Process: Techniques That Transform Grain into Flour

The journey of transforming grain into flour begins with an intricate milling process that blends traditional artistry with modern technology. At the heart of this process lies the selection of grain varieties, which significantly influences the quality of the final product. Millers carefully choose grains based on their protein content, hardness, and moisture levels. Each type of cereal—be it wheat, corn, or rice—requires its unique milling method to unlock the potential within. The process typically consists of several key steps including:

- Cleaning: Removing impurities and foreign particles from the grain.

- Conditioning: Adding moisture to prepare the grain for milling.

- Milling: Crushing and grinding grains into flour.

- Separation: Sifting the flour to achieve desired texture and consistency.

Once the grain is prepared, it goes through a series of milling methods that harness different techniques to achieve flour with specific attributes. The two primary milling methods include stone milling and roller milling. Stone milling employs traditional stone grinders, allowing for a coarser-textured flour while preserving the natural oils and nutrients of the grain. Roller milling, on the other hand, uses modern machinery to produce a fine-textured flour ideal for industrial baking. A brief comparison of these methods highlights their distinct characteristics:

| Milling Method | Texture | Nutritional Preservation |

|---|---|---|

| Stone Milling | Coarse | Higher |

| Roller Milling | Fine | Moderate |

Quality Control in Milling: Ensuring Consistency and Purity for Optimal Baking

In the intricate process of milling, quality control acts as the backbone, ensuring that every grain transforms into flour with exceptional consistency and purity. The journey from field to flour involves rigorous testing and monitoring of various parameters, such as moisture content, protein levels, and particle size. Each batch undergoes meticulous analysis to identify potential contaminants and to assess the flour’s suitability for specific baking applications. This not only guarantees that bakers receive a reliable product but also enhances the overall quality of the baked goods they produce.

To maintain the highest standards of quality, milling facilities employ a range of techniques and equipment, including:

- Testing Mills: Small-scale mills used to evaluate flour characteristics.

- Falling Number Tests: Measures enzyme activity in flour to predict dough performance.

- Color Measurement: Assures flour color is consistent and meets expectations for end products.

Additionally, regular audits of equipment and processes help identify areas for improvement, fostering an environment where quality is ingrained into every phase of production. A key aspect of this commitment to quality is the use of advanced technologies combined with time-honored practices, striking a balance that advances the art of milling while preserving its integrity.

Choosing the Right Flour: A Guide to Flour Types and Their Best Uses

Choosing the right flour can transform your culinary creations from ordinary to extraordinary. Each type of flour has unique characteristics that make it suitable for specific types of baked goods. For instance, all-purpose flour is a versatile choice, perfect for cookies, pancakes, and muffins. On the other hand, bread flour contains a higher protein content, making it the ideal candidate for yeast breads and rolls. Specialty flours like cake flour provide a lighter texture for cakes and pastries, while whole wheat flour offers a denser, nuttier flavor that enhances the nutritional value of your baked items.

When navigating your flour options, it’s essential to consider the texture and moisture content needed for your recipe. Keep in mind the following uses for various flour types:

- All-Purpose Flour: Best for general baking needs.

- Whole Wheat Flour: Perfect for hearty breads and baked goods.

- Cake Flour: Ideal for soft, tender cakes and cookies.

- Pastry Flour: Excellent for pies and pastries.

- Gluten-Free Flour: Great for those with gluten allergies, perfect for a variety of goods.

| Flour Type | Protein Content | Best Uses |

|---|---|---|

| All-Purpose | 10-12% | General baking |

| Bread | 12-14% | Yeast breads, rolls |

| Cake | 7-9% | Cakes, cupcakes |

| Whole Wheat | 13-15% | Whole grain breads |

| Gluten-Free | Varies | Bread, cookies for gluten-sensitive diets |

Understanding the diverse range of flours and their applications can greatly enhance your baking journey. Experimenting with different types not only broadens your culinary skills but also contributes to healthier and more personalized recipes. From the rustic charm of whole wheat to the delicate finesse of cake flour, each choice you make brings you a step closer to mastery in the kitchen.

To Conclude

As we conclude our exploration of cereal milling, we find ourselves deeply entwined in the intricate dance that transforms humble grains into the versatile flour that forms the backbone of countless culinary creations. The process, as we’ve unveiled, is not merely mechanical; it is a blend of tradition and innovation, art and science, where each step—whether grinding, sifting, or blending—tells a story of heritage and craftsmanship.

From the golden fields where grains are nurtured under the sun to the rustic sound of millstones turning, every grain carries with it the promise of nourishment. The hands that process these grains, imbued with wisdom passed down through generations, understand that milling is more than a job; it’s a commitment to quality and an acknowledgment of the bond between our food sources and sustenance.

As you embark on your next culinary adventure, remember the journey each grain has taken to become the flour in your pantry. With this newfound appreciation, may your baking be inspired and your meals enriched. Whether it’s a simple loaf of bread or a complex pastry, each bite is a celebration of the art of milling—a testament to dedication and the age-old connection between nature and our kitchens. Thank you for joining us on this enlightening journey from grain to flour. Happy baking!