exploring the Art and Science of Maize Milling

As the sun rises over golden fields, the vibrant hues of ripened maize dance in the gentle breeze, heralding the promise of conversion. Few crops have woven themselves as intricately into the fabric of human civilization as maize, known for its versatile applications that stretch from staple food to industrial products. At the heart of this metamorphosis lies the intricate process of maize milling, a practice that marries tradition and technology in a harmonious blend.

In this exploration, we delve into the nuanced world of maize milling, where centuries-old artisanal techniques coexist with cutting-edge machinery. This article uncovers the intricate craftsmanship involved in converting maize kernels into flour, meal, and grits, while also shedding light on the scientific principles that underpin each step of the milling process. From understanding the anatomy of the grain to the mechanics of milling operations, we invite you to join us on a journey that reveals not just the essentials of production, but the cultural and economic significance of maize milling across the globe.As we sift through the layers of history and innovation, we aim to illuminate how this humble grain continues to shape diets, economies, and even the future of enduring food practices.

Understanding the Historical Significance of Maize in Milling Practices

The journey of maize from a humble field crop to a staple ingredient in numerous cultures illuminates its rich historical significance, particularly in the realm of milling practices. Ancient civilizations, from Mesoamerican cultures to Indigenous peoples of North America, recognized maize not just as food but as a symbol of sustenance and survival. Early milling methods, such as the use of stone grinders, paved the way for the transformation of whole grains into a consumable form, increasing the accessibility of this vital resource.The grinding process was as much an art as it was a science, blending tradition with necessity, and even social interaction, as communities gathered to partake in milling activities.

As maize gained prominence, various milling techniques evolved alongside technological advancements. Throughout history, the milling of maize has played an essential role in shaping dietary habits and culinary practices, resulting in a plethora of unique products, each reflecting the local culture and regional preferences. Key milestones in maize milling include:

- Hand Grinding: Used for centuries, providing nutrition while fostering communal ties.

- Mechanical Mills: Revolutionized the speed and efficiency of maize processing in the Industrial Age.

- Modern Innovations: Incorporating advanced technology for higher yield and nutritional preservation.

the significance of maize milling extends beyond individual practices; it has profoundly influenced agricultural economies and trade relationships. The following table highlights some key aspects of maize milling’s cultural impact:

| Region | Maize Milling Method | Historical Influence |

|---|---|---|

| Mesoamerica | Tortilla mills | Fostered community sharing and culinary identity. |

| Southern united States | Stone grinding | Integral to local cuisine (e.g., cornbread). |

| Africa | mortar and pestle | Central to traditional ceremonies and feasts. |

The Mechanics Behind Efficient Maize Milling Techniques

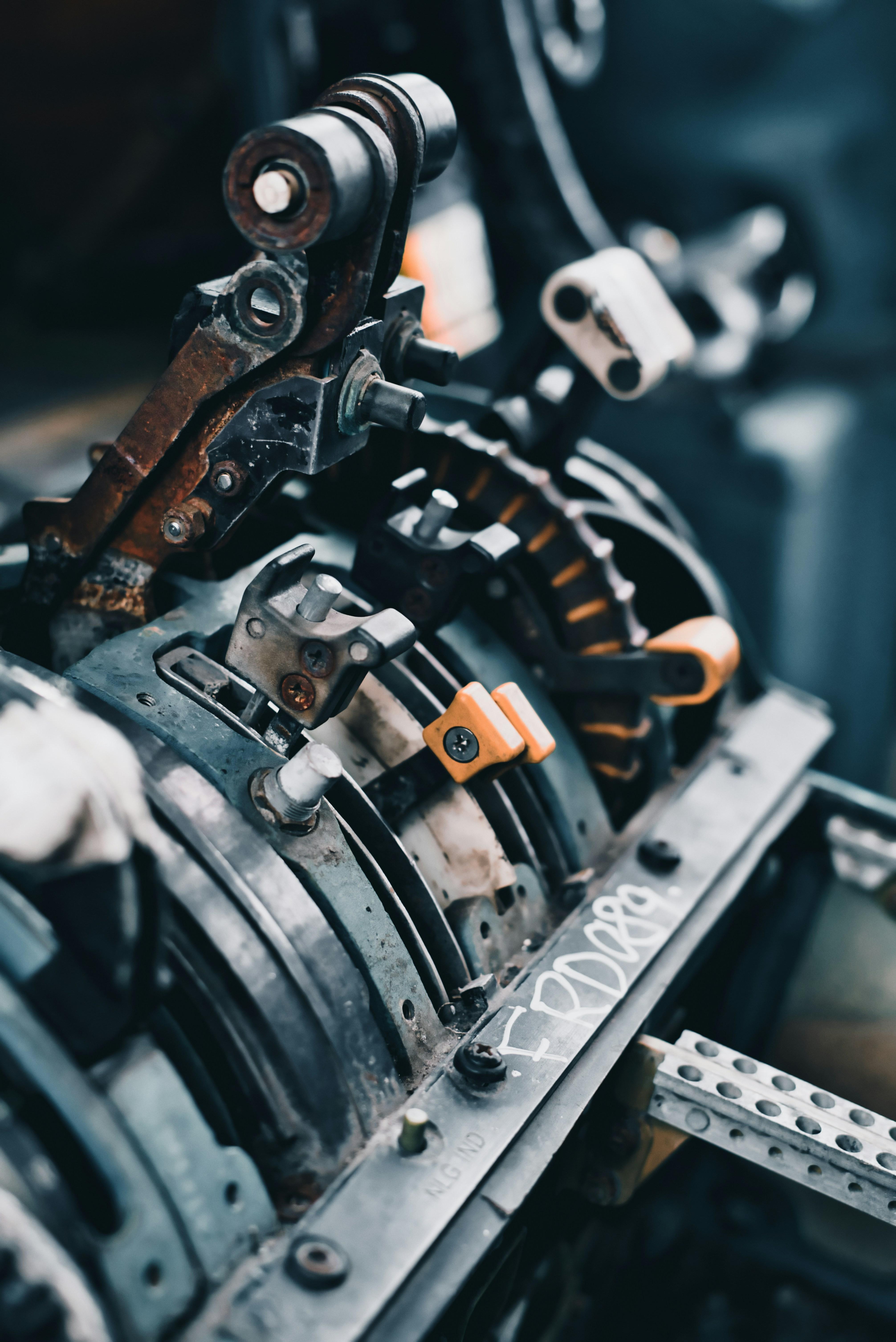

Understanding the intricacies of the maize milling process reveals its blend of art and science, crucial for maximizing efficiency and quality. Key mechanisms involved in maize milling include grinding, sifting, and separating. Each step utilizes specialized equipment designed to ensure minimal product loss and optimal quality. The grinding process often employs different types of mills such as roller, hammer, and plate mills, each offering unique benefits. roller mills are preferred for their ability to create uniform particle sizes, while hammer mills excel at breaking down tougher grains. The choice of milling technique influences the end product and nutritional value of the maize, making knowledge of these methods vital for any mill operator or food manufacturer.

Another aspect that enhances milling efficiency is the incorporation of technology and automation. Modern milling equipment allows for precise adjustments to be made during the milling process, resulting in a consistent and high-quality flour. the integration of real-time monitoring systems enables operators to track output and make adjustments on-the-fly, further reducing waste.Below is a concise table showcasing various milling methods and their key characteristics, emphasizing the importance of choosing the correct technique for desired outcomes.

| Milling Method | Advantages | Typical Uses |

|---|---|---|

| Roller Mill | Uniform particle size, high efficiency | Flour production, ingredient processing |

| Hammer Mill | Versatile, effective for coarse products | Animal feed, coarse flour |

| Plate Mill | Simple design, cost-effective | Small-scale milling, specialty flours |

Nutritional Insights and Innovations in maize Products

Maize, often celebrated for its versatility, boasts a wealth of nutritional benefits that enhance various dietary preferences. It is a significant source of essential nutrients, including carbohydrates, proteins, and dietary fiber. Moreover, the grains are rich in B vitamins (such as niacin and thiamine) and antioxidants, which play crucial roles in energy metabolism and overall health. Innovations in maize milling technology unlock new forms of maize products, allowing for enhanced nutrient retention while also expanding culinary applications. This has led to the creation of specialized products such as blue cornmeal, known for its higher anthocyanin content, and high-protein maize flour, perfect for bolstering the protein content in various dishes.

Furthermore,the rise of functional foods has sparked interest in fortified maize-derived items. Manufacturers now explore the incorporation of additional nutrients during the milling process, yielding enriched products that deliver both taste and health benefits. Some key innovations in this domain include:

- Fortified Cornmeal: Enhanced with vitamins and minerals, offering a nutrient power boost.

- Whole Grain Options: Retaining the bran and germ for greater fiber intake.

- Low Glycemic Index Flours: Aiding blood sugar management for diabetics.

To better illustrate the nutritional profile of some popular maize products, the following table highlights their key attributes:

| Product | Calories (per 100g) | Protein (g) | fiber (g) | Key Benefit |

|---|---|---|---|---|

| Yellow Cornmeal | 365 | 9 | 7 | Rich in antioxidants |

| White Corn Flour | 360 | 8 | 6 | Light and versatile |

| Blue Cornmeal | 350 | 10 | 5 | Higher in anthocyanins |

As the scientific community further investigates the health attributes of maize products, the possibilities for novel uses and health-oriented formulations seem boundless. The art and science of milling maize is evolving, paving the way for a future rich with nutritious options that cater to a variety of lifestyles and dietary needs.

Sustainable Practices for Modern Maize Milling Operations

The evolving landscape of maize milling operations necessitates a commitment to sustainability. By embracing practices that minimize environmental impact, modern facilities can ensure they meet regulatory standards while fostering a positive community image. This journey towards sustainability is underpinned by several key strategies:

- Energy Efficiency: Implementing energy-efficient machinery reduces power consumption, lowering operational costs and carbon footprints.

- Water Conservation: Utilizing closed-loop systems for cleaning and processing can substantially decrease water usage.

- Waste Management: Recycling by-products, such as husks and bran, can transform waste into valuable resources, used for animal feed or renewable energy generation.

- Local sourcing: Partnering with local farmers can not onyl support the regional economy but also decrease transportation emissions and ensure fresher raw materials.

Moreover, the incorporation of innovative technologies and agricultural practices can enhance production efficiency while adhering to sustainable principles. By integrating precision farming techniques, millers can optimize crop yields and reduce chemical usage. Furthermore, investing in research to develop drought-resistant maize varieties contributes to climate resilience.Here’s a snapshot of sustainable technology adoption in maize milling:

| Technology | Benefits |

|---|---|

| Solar-Powered Equipment | Reduces dependence on fossil fuels and cuts energy costs. |

| Smart Sensors | Monitor moisture levels and optimize milling processes, minimizing waste. |

| biogas Installations | transform organic waste into renewable energy, reducing landfill use. |

Future Outlook

In the hushed hum of milling machinery and the rich aroma of freshly ground maize, we uncover a world where art meets science. The journey through the intricate processes of maize milling reveals not only the transformation of grain into flour but also the deep cultural significance and innovative technologies entwined within this ancient practice. As we sift through the layers of tradition and modernity, we are reminded of the vital role maize plays in feeding communities and nourishing culinary creativity worldwide.

As we close this exploration, we invite you to appreciate the unseen craftsmanship behind each grain and the meticulous care that guides it from field to table. In understanding the nuances of maize milling, we become more connected to the foods we cherish and the processes that bring them to life. Whether you are an artisan baker,a food enthusiast,or simply a curious reader,may this journey inspire you to delve deeper into the rich tapestry of agricultural practices that have shaped our diets and our cultures. The next time you savor a dish made with maize,take a moment to reflect on the artistry and science that crafted it.after all, each bite tells a story—one of history, innovation, and the enduring bond between humanity and the land.