Introduction: Elevating Grains: The Art and Science of Cereal Processing

In the vast tapestry of human nutrition, grains serve as a foundational thread, intertwining cultures, histories, and cuisines across the globe. From the golden fields of wheat swaying under the sun to the hearty bounty of oats and barley, these humble crops have long been celebrated for their nourishment. Yet, behind the scenes of our morning cereals and baked goods lies a complex interplay of art and science—an intricate dance of transformation known as cereal processing. This multifaceted process elevates simple grains into versatile ingredients, enhancing flavors, textures, and nutritional profiles. As we delve into the realm of cereal processing, we uncover not just methods and techniques, but also the ingenuity that bridges tradition with innovation, ensuring that grains continue to play a pivotal role in our diets and our lives. Join us on this exploration of how grains are elevated, revealing the sophisticated craftsmanship that turns nature’s bounty into the essentials of our daily fare.

The Journey from Farm to Bowl: Understanding Grain Sourcing and Quality

The journey of grains from the field to our bowls is a meticulous process steeped in tradition and innovation. It begins on the farm, where varietal selection plays a crucial role in determining the quality and taste of the final product. Farmers often choose specific types of grains based on local climate conditions, soil composition, and consumer preferences. Once harvested, these grains undergo careful handling to preserve their natural qualities. Some key elements that farm-to-bowl journey encompasses include:

- Harvesting: Timely collection of grains to ensure optimal flavor and nutrient retention.

- Drying: Reducing moisture content to prevent spoilage and extend shelf life.

- Storage: Utilizing controlled environments to safeguard against pests and environmental factors.

Following harvest, the grains must be processed to enhance their usability and nutritional profile. This stage is an intersection of art and science, where various techniques come into play. From milling to parboiling, each step serves a specific purpose in transforming raw grains into versatile culinary staples. Among the notable processing methods, we can highlight:

| Processing Method | Description | Benefits |

|---|---|---|

| Milling | Crushing grains to separate the kernel from the husk. | Improves digestibility and texture. |

| Parboiling | Partial cooking of grains while still whole. | Enhances nutrient retention and reduces cooking time. |

| Toasting | Heating grains to develop flavor and aroma. | Adds complexity and enhances taste. |

Through these processes, grains evolve from simple agricultural products to high-quality ingredients, ready to be incorporated into a variety of dishes, from breakfast cereals to artisanal bread. As this journey unfolds, a commitment to sourcing and quality remains paramount, ensuring that every bite celebrates the rich tapestry of grain cultivation and processing.

Unlocking Flavor and Nutrition: The Science Behind Grain Processing Techniques

Grain processing is a captivating intersection of art and science, where traditional methods are enhanced by modern technology to unlock the full potential of cereal grains. Techniques such as milling, fermentation, and extrusion play a crucial role in breaking down complex structures, making nutrients more bioavailable. By using milling, grains are finely ground, increasing their surface area and allowing for easier digestion. Fermentation introduces beneficial microorganisms that not only enhance flavor but also enrich grains with additional nutrients, including B vitamins and probiotics. Meanwhile, extrusion transforms grains into a variety of textures, often used in snacks and breakfast cereals, improving their appeal while retaining essential nutrients.

To truly appreciate the impact of these methods, it is essential to understand their contribution to both flavor and nutrition. For example, the nutritional profile of a processed grain can change dramatically based on the technique used. Here’s a brief comparison of some common processes:

| Processing Technique | Flavor Enhancement | Nutritional Impact |

|---|---|---|

| Milling | Increases surface area for flavor release | Can reduce fiber if bran is removed |

| Fermentation | Introduces unique flavors and aromas | Boosts vitamin content and digestibility |

| Extrusion | Creates appealing textures and colors | Can enhance nutrient absorption |

Exploring grain processing techniques reveals the delicate balance that must be struck between nutritional integrity and sensory characteristics. With each method employed, the art of balancing outcome and purpose defines how grains are perceived and consumed. Understanding the science behind these processes not only educates consumers but also guides producers in making informed decisions that support both health and culinary diversity.

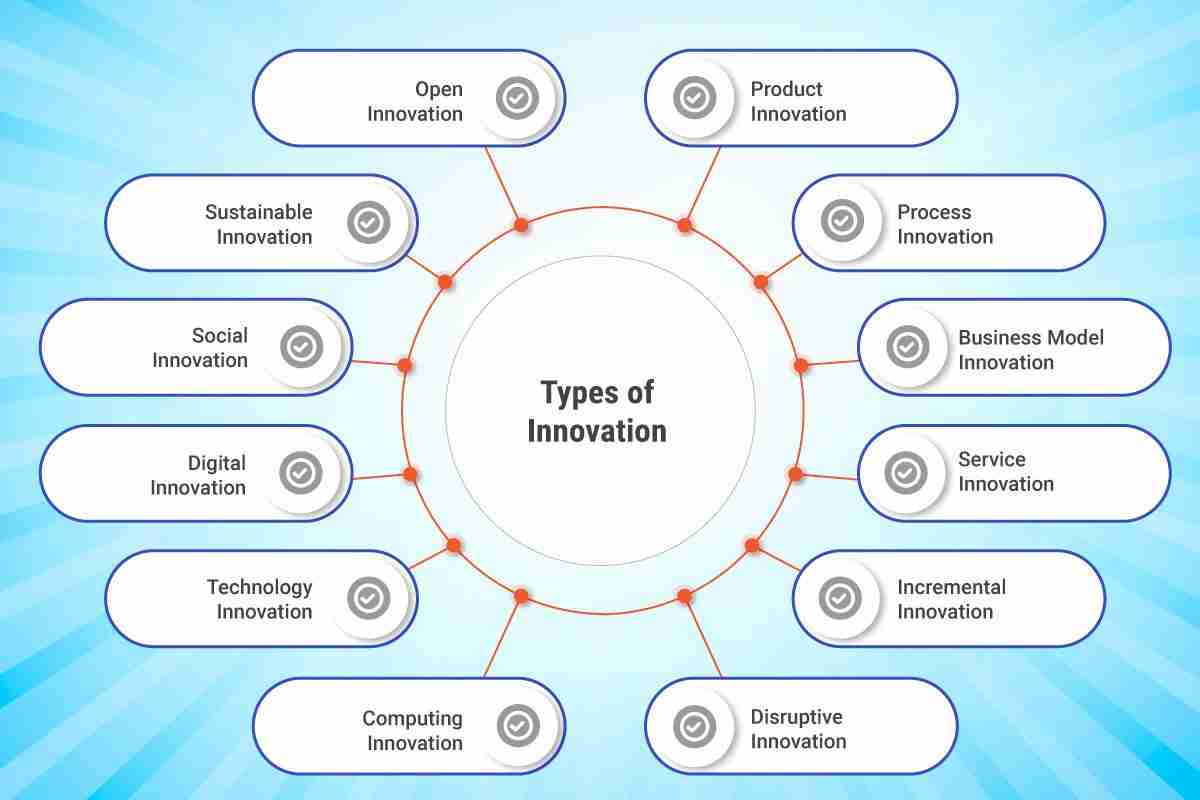

Innovative Processing Methods: Enhancing Texture and Shelf Life of Cereals

Advancements in cereal processing have revolutionized the way we enjoy our grains, transforming them into products that are not only nutritious but also appealing to the palate. By employing innovative techniques such as extrusion, steam cooking, and fermentation, producers can enhance both the texture and the shelf life of cereals significantly. These methods work by altering the physical and chemical properties of grains, allowing them to retain moisture and flavor while improving digestibility. For instance, the use of extrusion not only creates a diverse range of shapes and textures, from crunchy flakes to puffed cereals, but also facilitates the incorporation of additional nutrients and flavors, catering to the evolving demands of health-conscious consumers.

In addition to improving texture, modern processing methods help maximize the longevity of cereal products. Techniques such as controlled storage atmospheres and packaging innovations, including vacuum sealing and barrier materials, minimize exposure to oxygen and moisture, significantly delaying spoilage. The impact is profound; products remain fresher for extended periods without compromising quality. Consider the following table that showcases some innovative processing methods and their benefits:

| Method | Benefits |

|---|---|

| Extrusion | Enhances texture, shape variety, and nutrient retention |

| Steam Cooking | Improves softness and digestibility |

| Fermentation | Increases flavor complexity and probiotic content |

| Controlled Storage | Extends shelf life and maintains freshness |

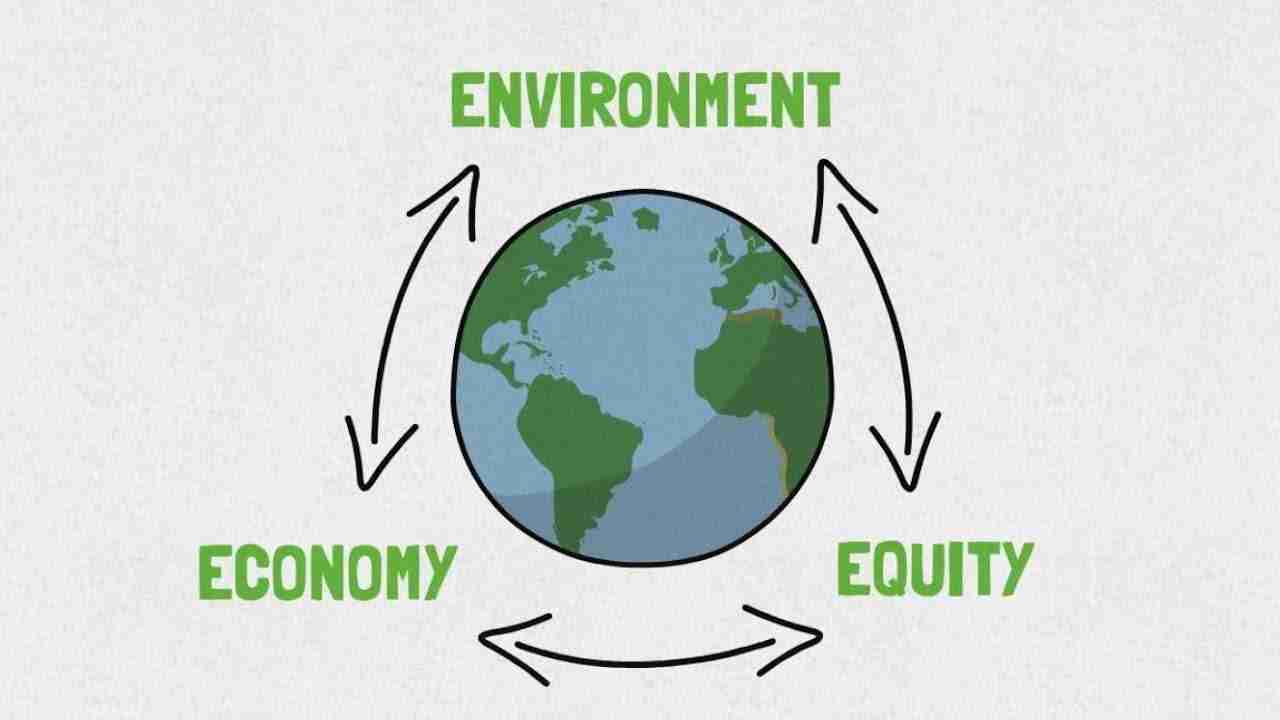

Sustainability in the Grain Industry: Best Practices for Eco-Friendly Processing

In the quest to cultivate a sustainable future, the grain industry has made significant strides by incorporating eco-friendly processing practices. Reducing energy consumption plays a pivotal role, with many facilities now utilizing renewable energy sources, such as solar and wind. This commitment not only lowers the carbon footprint but also enhances resource efficiency. Furthermore, waste reduction techniques, including recycling byproducts and minimizing water usage, contribute to a circular economy that benefits both producers and the environment. Advanced technologies, such as smart sensors and AI-driven analytics, have revolutionized traditional processing methods, allowing for precise control over resources and improved yield quality.

Another essential aspect of sustainability in grain processing involves careful ingredient sourcing and supply chain transparency. Choosing local suppliers reduces transportation emissions and supports regional economies, while ensuring the grains are grown under sustainable agricultural practices. Moreover, implementing organic certification and adhering to best practices in soil health and biodiversity can enhance product appeal to increasingly conscientious consumers. To encapsulate these strategies, the following table highlights some best practices that grain processors can adopt to foster a more sustainable approach:

| Best Practice | Description |

|---|---|

| Renewable Energy Utilization | Incorporating solar panels or wind turbines to power processing facilities. |

| Waste Recycling | Recycling husks and bran into animal feed or compost. |

| Water Efficiency | Implementing closed-loop systems to minimize water use. |

| Local Sourcing | Collaborating with nearby farmers for reduced transport emissions. |

| Organic Practices | Complying with organic standards to promote sustainable farming. |

Key Takeaways

the journey through the world of cereal processing reveals a fascinating interplay between art and science, where ancient traditions meet modern innovations. As we have explored, elevating grains involves not just a meticulous understanding of their botanical nature, but also a creative approach to transforming them into nutritious, appealing products. From selecting the finest seeds to applying cutting-edge technologies, each step illuminates the depth of expertise involved in making cereals a staple of our diets.

As we move forward, it is important to appreciate the complexities behind the foods we often take for granted. The next time you pour a bowl of your favorite cereal, remember the rich tapestry of knowledge and craftsmanship that elevates simple grains into nourishing meals. By continuing to honor this intricate process, we can ensure that the art of cereal processing thrives, adapting to our evolving tastes and nutritional needs—celebrating both tradition and innovation, shaping the future of our food.