Crafting Grains: The Art and Science of Cereal Milling

In the quiet hum of grain mills across the globe, a fascinating interplay of artistry and science unfolds—a delicate dance that transforms humble seeds into the flour that nourishes our daily lives. Cereal milling, a time-honored tradition steeped in history, is not merely a mechanical process; it is a nuanced craft that harmonizes the physical properties of grains with the alchemical principles of cooking and baking. From the ancient stone mills of Mesopotamia to today’s state-of-the-art facilities, the journey of grains encompasses both innovation and tradition, reflecting the cultures and cuisines that rely on them. In this exploration of cereal milling, we delve into the intricate methods, technological advancements, and the passionate artisans who keep this vital craft alive, illuminating the rich tapestry of flavors and textures that begin with a single grain. Join us as we uncover the secrets behind the milling process—where each kernel tells a story, and each batch of flour holds the promise of culinary creativity.

Exploring the Milling Process: From Field to Flour

At the heart of cereal milling lies a meticulous process where nature’s bounty transforms into the flour that serves as the foundation for countless culinary creations. The journey begins in the fields, where grains such as wheat, rye, and barley are cultivated with precision. Each crop cycle is a dance between the elements and human stewardship, ensuring that only the best grains make it to the mill. Once harvested, these grains undergo a series of critical steps before reaching the mill, including cleaning, drying, and tempering—essential processes that prepare the grains for milling and enhance their baking properties.

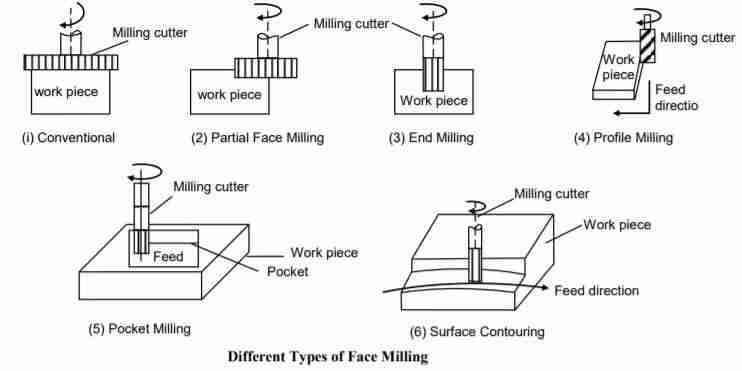

The milling stage itself is a symphony of art and technology. Grist milling begins with grinding the grains into flour, using a variety of methods such as stone milling or roller milling. The choice of method affects the flour’s end texture, flavor, and nutritional content. Throughout this process, the miller carefully monitors factors such as moisture levels, particle size, and extraction rates. Each parameter is carefully balanced to yield a flour that meets specific baking needs. Below is a simple table highlighting the difference between the two main milling methods:

| Milling Method | Description | Common Uses |

|---|---|---|

| Stone Milling | Traditional method where grains are ground between two stones. | Artisan bread, specialty flours |

| Roller Milling | Modern technique using metal rollers for rapid, efficient processing. | Bread flour, all-purpose flour |

This intricate journey highlights the intersection of agriculture and technology, where millers are not just processors but custodians of the grain’s heritage. With each bag of flour produced, the essence of its origin—the fields, the soil, and the growers—remains an integral part of what makes baking such a cherished craft. Understanding these processes can deepen our appreciation for the humble flour, transforming simple recipes into masterpieces of culinary art.

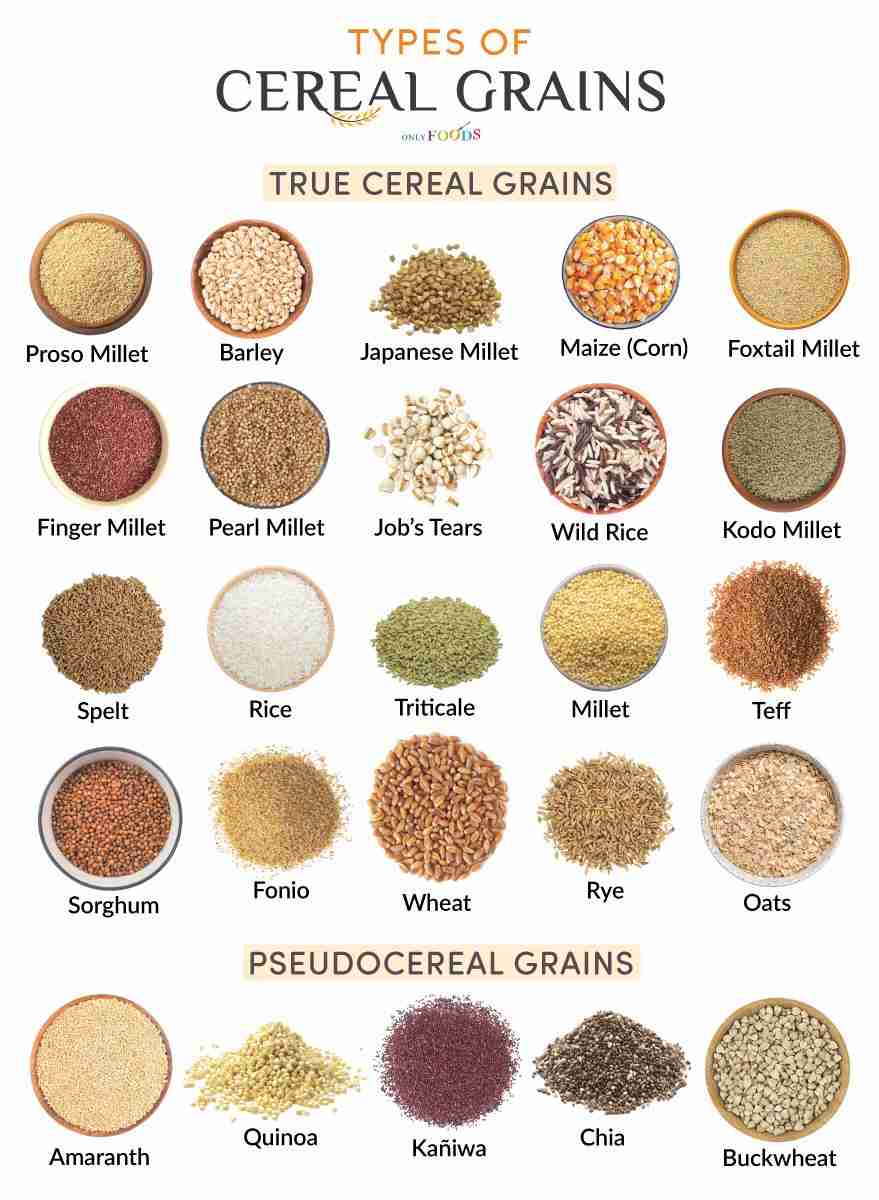

Understanding Grain Varieties: Choosing the Right Ingredient

When delving into the world of cereal milling, an essential aspect lies in understanding the different varieties of grains available. Each type of grain offers unique flavors, textures, and nutritional properties that can significantly impact the final product. For instance, hard wheat varieties, known for their high protein content, are perfect for producing bread and pasta, fostering robust structures and chewiness. On the contrary, soft wheat is ideal for cakes and pastries, providing a delicate crumb and tender feel. Additionally, grains such as barley, oats, and rye introduce distinct flavors and health benefits, expanding the culinary horizons for bakers and chefs alike.

As you select the right grain for your needs, consider factors such as seasonality, availability, and end use. Incorporating a diverse range of grains can enhance the nutritional profile of your products, tapping into the growing consumer demand for healthier options. Here’s a quick reference table to assist you in choosing the right grain variety:

| Grain Variety | Best Use | Key Benefits |

|---|---|---|

| Hard Wheat | Bread, Pasta | High protein, chewy texture |

| Soft Wheat | Cakes, Pastries | Tender crumb, light texture |

| Barley | Soups, Stews | High fiber, nutty flavor |

| Oats | Granola, Baked Goods | Rich in nutrients, heart-healthy |

| Rye | Bread, Crackers | Distinct taste, good for digestion |

The Role of Technology in Modern Cereal Milling

As the art of cereal milling evolves, the infusion of advanced technology is reshaping every aspect of this age-old craft. Precision milling techniques, powered by cutting-edge machinery, enable millers to extract the maximum potential from each grain. Modern mills utilize state-of-the-art grinding equipment that optimizes particle size and promotes uniformity. Notably, the integration of computerized controls streamlines the milling process, allowing for real-time adjustments to optimize output and minimize waste. Sensors monitor variables such as moisture content, temperature, and flow rate, ensuring that every batch meets stringent quality standards.

Furthermore, the implementation of data analytics tools in the milling process offers millers insights that were once unattainable. By harnessing large datasets, millers can predict trends, manage supply chains efficiently, and maintain consistent product quality. The automation of routine tasks not only enhances productivity but also allows skilled workers to focus on creative aspects of milling, such as developing unique flour blends. Additionally, innovations in packaging technology are enhancing the shelf life and freshness of flour, ensuring that consumers receive the best quality. As technology continues to advance, the interplay between tradition and innovation in cereal milling crafts a future where the essence of grains is preserved and celebrated.

Enhancing Quality and Flavor: Techniques for Ideal Milling Outcomes

When it comes to achieving exceptional milling outcomes, a nuanced understanding of grain quality and preparation techniques plays a pivotal role. To maximize flavor and texture, millers should focus on the following critical aspects:

- Grain Selection: Choose high-quality grains that have been specifically bred for milling. Varieties with superior protein content and gluten strength can lead to a more favorable end product.

- Moisture Control: Maintaining optimal moisture levels is essential. Excess moisture can lead to spoilage, while too little can hinder the milling process. Ideal moisture content typically ranges from 12-14%.

- Cleaning and Preparation: Thoroughly clean grains to remove debris, dust, and contaminants. Pre-conditioning grains by soaking them briefly can also improve milling efficiency by making them easier to break down.

Implementing a careful milling process further enhances the quality of the final product. Here are some methodologies to consider:

| Technique | Description |

|---|---|

| Stone Milling | Uses natural stones to grind grains, preserving flavor and nutrients. |

| Air Classifying | Separates particles based on size using air, resulting in a cleaner and more uniform flour. |

| Variable Speed Milling | Adjusting the speed of millers can optimize particle size and texture, catering to specific market demands. |

By implementing these strategies, millers can ensure a product that resonates with consumers’ palates while maintaining the integrity of the grain. This careful orchestration of techniques not only enhances the sensory attributes of flour but also strengthens the overall milling process, creating a sustainable cycle of quality production.

Closing Remarks

As we conclude our exploration into the intricate world of cereal milling, it becomes evident that this age-old practice is a harmonious blend of tradition and innovation. The meticulous art of crafting grains not only transforms humble kernels into a diverse array of flour but also echoes the rich heritage and evolving trends of nourishment and culinary creativity.

From the grinding stones of ancient civilizations to the sophisticated machinery of modern mills, every milestone reflects our unwavering quest for quality and sustainability in food production. As we celebrate the artisans and scientists dedicated to perfecting this craft, we also recognize their role as stewards of the grain—balancing the needs of consumers with the imperatives of the environment.

Whether you’re a passionate home baker, a professional chef, or simply an enthusiastic eater, understanding the nuances of cereal milling enhances our appreciation for the foods we cherish. So, the next time you sprinkle flour on your countertop or savor a warm loaf fresh from the oven, take a moment to honor the rich tapestry of craftsmanship that has made it all possible. In the grain, we find not just sustenance, but a story—woven through time, culture, and community.