Step inside the bustling world of modern rice production as we explore “The Rice Factory: Inside a Modern Paddy Processing Unit.” Discover the innovative technology, intricate processes, and skilled workforce that come together to transform humble grains of paddy into the staple food that feeds millions around the world. Join us on a fascinating journey through the heart of this essential industry, where tradition meets cutting-edge efficiency to create the rice we know and love.

- The Technology Behind Paddy Processing: Automation and Efficiency

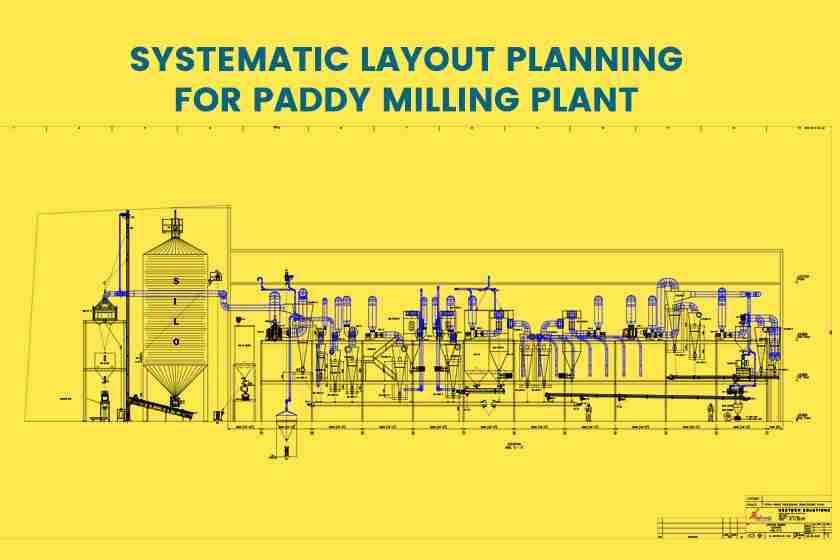

In a modern paddy processing unit, automation and efficiency are the backbone of the operation. By utilizing cutting-edge technology, these facilities are able to streamline the rice production process and maximize output. One of the key technologies used in these units is automated sorting machines, which can quickly and accurately separate the rice grains from impurities such as stones, twigs, and husks. This ensures that only the highest quality rice makes it to the final product.

Another important technology used in paddy processing is computerized monitoring systems. These systems keep track of key metrics such as moisture levels, temperature, and quality control throughout the entire production process. With real-time data analysis, operators can make adjustments as needed to optimize efficiency and ensure consistency in the final product. Overall, the integration of automation and technology in paddy processing units has revolutionized the industry, allowing for faster production times, higher quality rice, and increased profitability for manufacturers.

– Environmental Sustainability in Rice Production: From Water Management to Waste Reduction

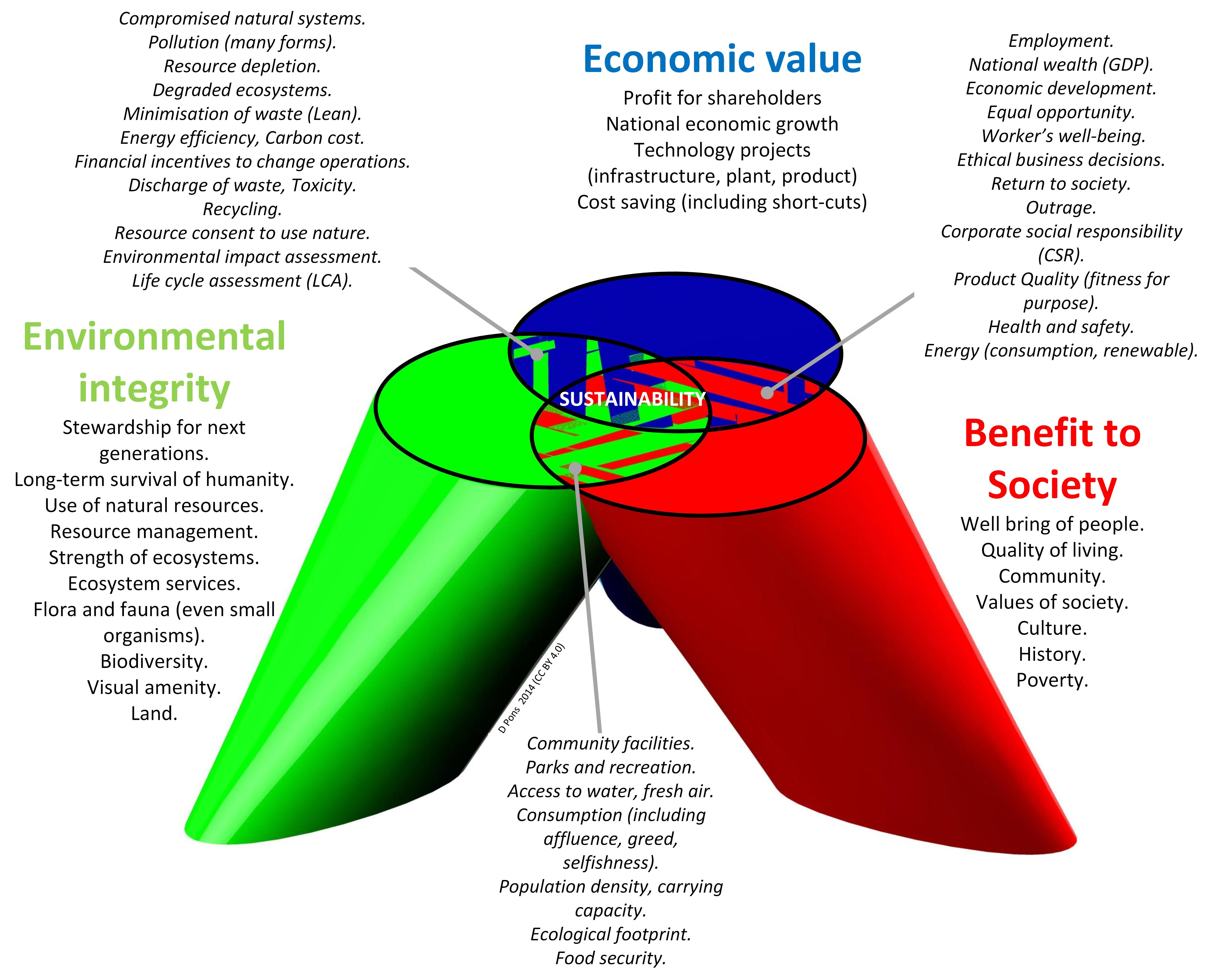

Step inside The Rice Factory, a cutting-edge paddy processing unit that exemplifies environmental sustainability in rice production. At the heart of this modern facility is a sophisticated water management system that efficiently utilizes water resources, minimizing waste and conserving this precious natural resource. The use of advanced technologies such as drip irrigation and water recycling ensures that every drop counts, reducing the environmental footprint of rice production.

- Water Management: Implementing drip irrigation and water recycling techniques

- Waste Reduction: Utilizing by-products for biogas production and composting

Furthermore, waste reduction is a key focus at The Rice Factory. By utilizing by-products such as rice husks and straw for biogas production and composting, the facility minimizes waste and reduces its impact on the environment. This sustainable approach not only benefits the planet but also contributes to the circular economy by turning waste into valuable resources.

– Quality Control Measures: Ensuring Safe and Nutritious Rice for Consumers

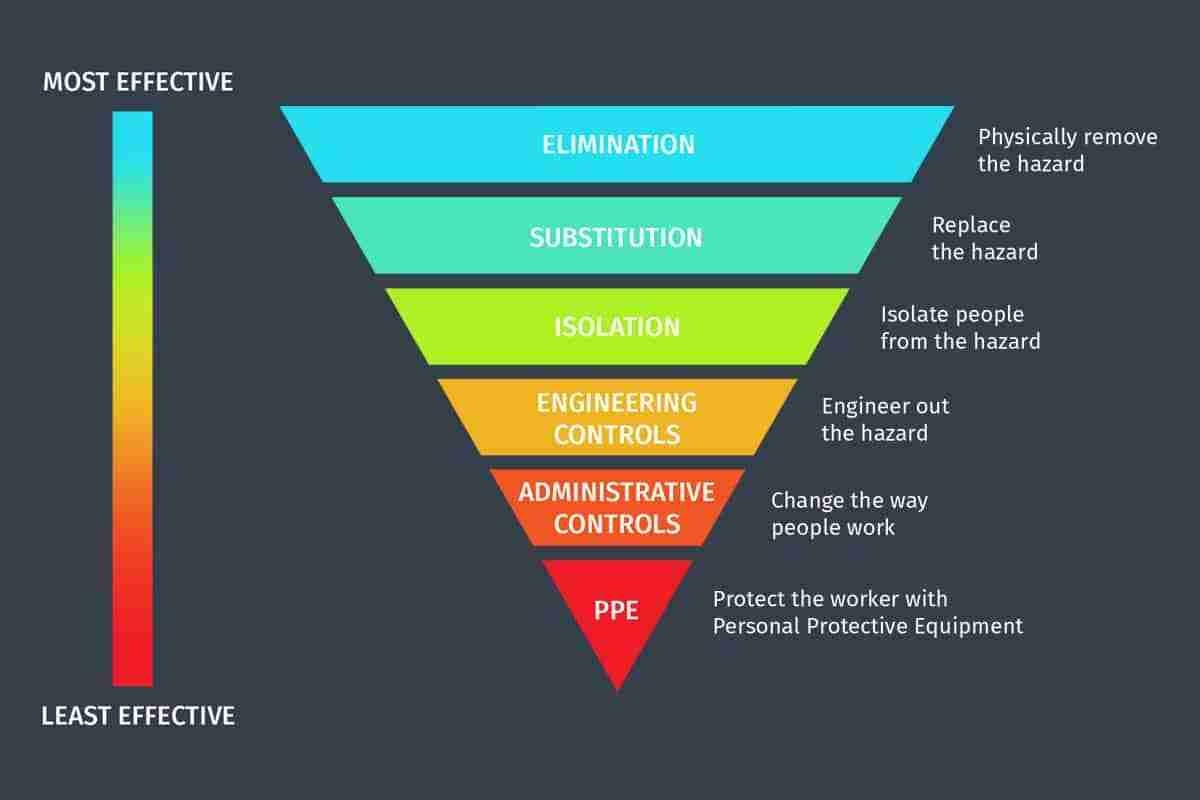

At The Rice Factory, we take great pride in our commitment to quality control measures to ensure that our consumers receive safe and nutritious rice products. Our modern paddy processing unit is equipped with state-of-the-art technology and stringent protocols to guarantee the highest standards of quality.

By implementing a series of quality control measures, we are able to maintain the integrity of our rice products throughout the production process. These measures include **regular inspections** at every stage of processing, **testing for contaminant levels**, and **adhering to strict hygiene practices** in our facilities. Our dedicated team of experts works tirelessly to uphold these standards, ensuring that each grain of rice that leaves our factory is of the highest quality.

In Summary

As we bid adieu to The Rice Factory, we are left with a newfound appreciation for the intricate process behind our daily staple. From the lush green paddies to the whirring machines of the processing unit, each step plays a crucial role in bringing the humble grain to our tables. Next time you tuck into a steaming bowl of rice, take a moment to savor not just the taste, but the journey it took to get there. And remember, the next time you pass by a paddy field, it’s not just a sea of green – it’s a testament to the hard work, dedication, and ingenuity of those behind The Rice Factory.