Rice, known as the staple food for more than half of the world’s population, undergoes a fascinating transformation from paddy fields to dinner tables. However, the intricate process of rice milling often remains a mystery to many. In this article, we delve into the enigmatic world of rice milling units, uncovering the secrets behind this essential step in the journey of rice from harvest to consumption. Join us as we explore the complexities and intricacies of unlocking the mysteries of rice milling units.

Understanding the Importance of Proper Rice Milling Techniques

Rice milling units play a crucial role in ensuring that the rice we consume is of high quality and safe for consumption. Proper rice milling techniques are essential for removing impurities, husks, and bran from the rice grains, resulting in clean and polished rice ready for cooking. Understanding the importance of these techniques can help us appreciate the efforts that go into processing the rice we eat on a daily basis.

One key aspect of proper rice milling is the removal of impurities such as stones, dirt, and other foreign particles that may be present in the raw rice grains. This process not only enhances the appearance of the rice but also improves its taste and texture. Additionally, proper milling helps to preserve the nutritional value of the rice, ensuring that essential vitamins and minerals are retained during the processing. By unlocking the secrets of rice milling units, we can gain a deeper appreciation for the meticulous work that goes into producing the rice we enjoy in our meals.

Key Components of an Efficient Rice Milling Unit

One of the essential components of a highly efficient rice milling unit is a high-quality rice huller. This machine is responsible for removing the outer husk of the rice grains, allowing for further processing. A good rice huller should be durable, easy to operate, and produce a high yield of properly hulled rice.

Another key component of a successful rice milling unit is a precise rice whitener. This machine is crucial for polishing the rice grains and removing any remaining bran layers, resulting in a clean and uniform final product. An efficient rice whitener should be able to adjust the degree of polishing to meet the desired rice quality standards.

Maximizing Yield and Quality Through Advanced Milling Technologies

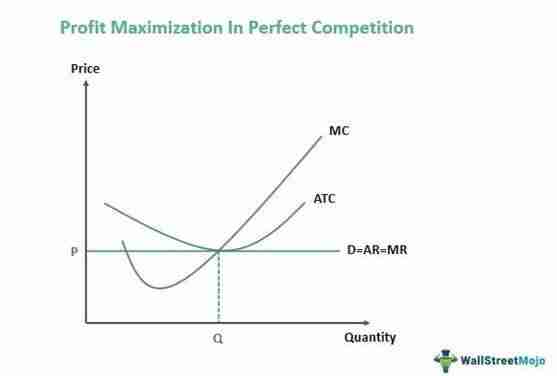

Rice milling units play a crucial role in enhancing the yield and quality of rice production. By utilizing advanced milling technologies, farmers and millers can unlock the secrets to optimizing their output. These cutting-edge technologies help ensure that every grain of rice is processed efficiently, resulting in higher yields and superior quality rice products.

With the use of state-of-the-art milling equipment, such as precision rice polishers and modern huskers, rice millers can achieve a higher milling yield and produce rice with better texture and flavor. By implementing automation and control systems in the milling process, millers can also reduce product waste and improve overall efficiency. Embracing these advanced technologies is key to maximizing yield and quality in rice milling units, ultimately leading to greater success for farmers and millers alike.

Optimizing Operation and Maintenance Practices for Long-term Success

Rice milling units play a crucial role in the food industry, ensuring that grains are processed efficiently and effectively. To unlock the secrets of these units, it is important to focus on . By implementing the following strategies, rice mill owners can improve their overall operations and increase their profitability:

- Regular maintenance: Schedule routine maintenance checks to ensure that all equipment is in good working condition. This can help prevent costly breakdowns and downtime.

- Invest in technology: Consider upgrading to modern machinery and equipment that can improve efficiency and quality of output.

- Employee training: Provide ongoing training for staff to ensure they are knowledgeable about the latest techniques and best practices in rice milling.

- Data analysis: Use data analytics to track performance metrics and identify areas for improvement in the milling process.

In the table below, we have highlighted some key maintenance tasks that should be performed regularly to keep a rice milling unit operating at its best:

| Maintenance Task | Frequency |

|---|---|

| Cleaning of machinery | Weekly |

| Lubrication of moving parts | Monthly |

| Inspection of electrical components | Quarterly |

| Calibration of equipment | Annually |

Future Outlook

As we conclude our exploration into the intricate world of rice milling units, we have uncovered the hidden art and science behind the process of turning raw rice grains into the polished pearls we find on our plates. From the precision machinery to the skilled labor, each aspect plays a vital role in unlocking the secrets of rice milling. Next time you enjoy a bowl of rice, remember the journey it took to reach your table and savor each grain with newfound appreciation. Let us continue to unravel the mysteries of this ancient culinary craft and appreciate the beauty of rice milling units in all their glory.