Inside the Rice Milling Unit: Transforming Grain to Goodness

At the heart of every great meal lies an essential staple that has nourished civilizations for thousands of years: rice. From the fragrant dishes of Asia to the comforting bowls across the globe, this humble grain is more than just a source of sustenance; it is a symbol of culture, tradition, and innovation. Yet,the journey of rice from field to table is frequently enough overlooked,with much of its transformation occurring in the unseen realms of the milling unit. Here, in these bustling hubs of activity, raw grain undergoes a meticulous process that shapes its final form, turning simple paddy into shiny, polished rice ready to make its culinary debut. In this article, we invite you to step inside a rice milling unit, where modern technology and age-old techniques converge to create not just a food product, but a vital ingredient woven into the fabric of daily life. Join us as we explore the intricate mechanics,the human touch,and the deep-rooted traditions that collectively transform grain into goodness.

Exploring the Journey of Rice: From Field to Mill

Behind every grain of rice lies a story woven through labor, tradition, and innovation. As paddy fields sway gently in the breeze, farmers nurture each stalk, ensuring optimal growth conditions for their season’s yield. This cultivation phase is critical, yet it is just the beginning of the rice’s transformative journey. Once harvested, the grains travel to the milling unit, where the real magic happens. Here, they undergo meticulous processes aimed at preserving their nutritional value while enhancing taste and texture. A combination of state-of-the-art technology and age-old methods ensures that the transformation is seamless and efficient.

Inside the milling unit, an array of processes takes place, working in harmony to convert rough, unpolished grains into the delightful rice varieties we cherish. This process typically includes:

- Cleaning: removing any debris or impurities.

- Husking: Separating the outer husk from the grain.

- Milling: Polishing the rice to achieve the desired finish.

- Sorting: Ensuring quality control by grading grains based on size and quality.

The efficiency of these stages is reflected in the final product, which can vary from whole grain brown rice to the classic white rice. Each type has its own unique benefits, catering to diverse culinary practices around the world. The meticulous attention to detail not onyl optimizes yield but also honors the heritage of rice cultivation, making the journey from field to plate a tale worth savoring.

unveiling the Milling process: techniques That Enhance quality

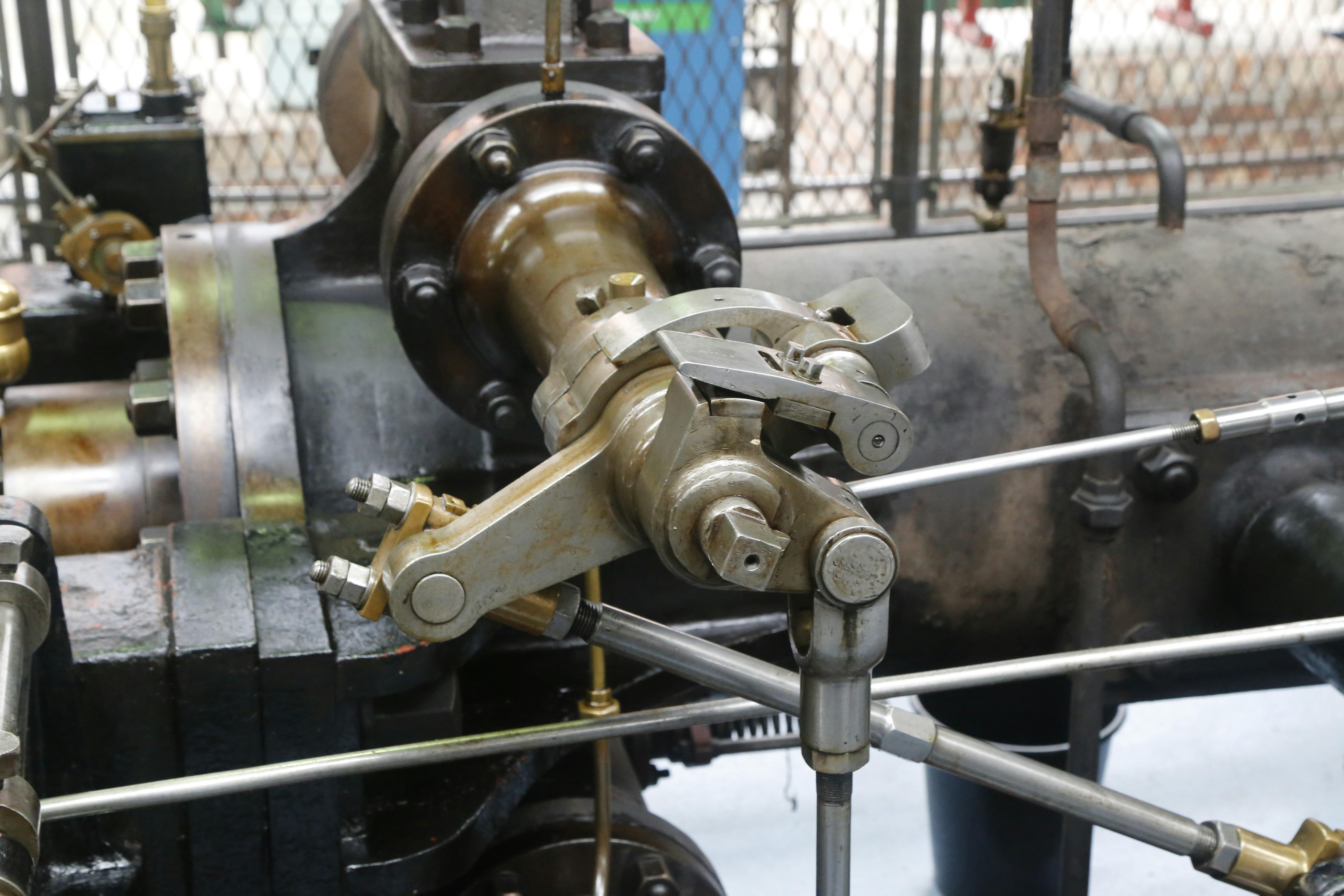

The milling process is a crucial aspect of transforming raw rice into a finished product, maintaining both quality and nutritional value. Several techniques play pivotal roles in ensuring that the milled grain meets consumer expectations while preserving its health benefits. Among these techniques, advanced hulling employs precision machinery that removes the outer husk without damaging the delicate kernel inside. This harmonious balance ensures that the rice retains its natural qualities while eliminating unwanted debris. additionally,the polishing process enhances the grain’s visual appeal,making it shine and further attracting buyers. Yet, it’s not just about aesthetics; careful polishing techniques also help reduce breakage, ensuring that more whole grains reach the market.

To enhance the quality further, grading is employed to categorize rice based on its size and quality. This ensures that consumers receive uniform grains, which not only promotes an appealing appearance but also guarantees consistent cooking times and textures. Innovations in de-stoning technology have also significantly improved the overall milling process. By effectively removing stones and impurities, this technique minimizes the risk of consumer dissatisfaction and enhances the overall quality of the final product. In addition to these techniques, maintaining optimal operating conditions, such as humidity control and temperature monitoring, is essential for preserving the grain’s freshness and flavor.Together, these processes create an efficient and refined milling operation that emphasizes quality at every step.

| Technique | Benefit |

|---|---|

| Hulling | Removes husk without damaging the grain |

| Polishing | Enhances visual appeal and reduces breakage |

| Grading | Ensures uniformity in size and quality |

| De-stoning | Minimizes impurities and enhances quality |

Maximizing Efficiency in the Rice Milling Unit: Best practices for Success

Enhancing productivity in a rice milling unit is crucial to meeting demand while ensuring quality. It’s essential to focus on key strategies that streamline operations and reduce waste. Among the most effective methods are:

- Regular Equipment Maintenance: Schedule routine checks to keep machinery in optimal condition.

- Staff Training: Invest in training programs to equip employees with the skills needed for efficient operations.

- Process Automation: Utilize automated systems for monitoring and controlling milling processes to minimize human error.

- Quality Control Checks: Implementing rigorous quality assessments at each stage ensures that only the best product reaches the market.

Another facet of improving efficiency lies in optimizing the workflow. Analyzing each step of the milling process can reveal bottlenecks and opportunities for enhancement. Consider the following elements:

| Process Stage | Optimizing Action |

|---|---|

| Receiving | Use an electronic tracking system for inventory management. |

| Milling | Adjust workflows to minimize downtime between batches. |

| Packaging | Implement speed enhancements through automated packaging solutions. |

Adopting these best practices can lead to meaningful improvements,allowing rice milling units to operate at peak performance and transform raw grains into high-quality products efficiently.

Sustainability in Rice Production: Innovations for a Greener future

In the quest for environmentally friendly agricultural practices, rice production has witnessed a wave of innovation aimed at reducing its carbon footprint while enhancing productivity. One such advancement is the integration of enduring milling techniques that minimize waste and energy consumption. Modern rice milling units are adopting cutting-edge technology, such as solar-powered machines and biomass energy systems, to further decrease their reliance on fossil fuels.This shift not only helps in conserving natural resources but also cuts down on pollution,helping to create a cleaner environment for future generations.

Moreover, various rice milling units are implementing zero-waste policies, turning byproducts into valuable resources.These units are collecting *rice husks*, *bran*, and *broken rice* to produce biofuel, animal feed, and even biodegradable packaging materials. Such initiatives exemplify modern ingenuity and the potential for a circular economy within the rice industry. To illustrate these efforts, consider the table below displaying common byproducts and their innovative uses:

| Byproduct | Innovative Use |

|---|---|

| Rice Husks | Biofuel production |

| Rice Bran | Animal feed & health supplements |

| Broken Rice | Biodegradable packaging |

To Conclude

As we conclude our exploration of the intricate journey within the rice milling unit, we are reminded of the extraordinary transformation that takes place within its walls. Each grain of rice, once a humble seed, undergoes a meticulous process that not only preserves its nutritional value but also enhances its culinary potential. from hulling to polishing,every step is a testament to human ingenuity and dedication to quality.

The milling unit stands as a bridge between the farmer’s harvest and our dining tables, embodying the very essence of agrarian innovation. As we savor the fragrant aroma of freshly cooked rice, let us appreciate the unseen labor and technology that work tirelessly to deliver this staple food to our plates.

In understanding the significance of these operations, we gain a deeper respect for the agricultural systems that sustain us. The next time you enjoy a bowl of rice, remember the journey it took—from the fields of golden grains to the milling unit, and ultimately, to your home. It’s a reminder that behind every meal lies a world of effort, expertise, and commitment to quality.