Harvesting Success: The Art and Science of Maize Milling

In the golden fields where maize dances under the gentle caress of the sun, a remarkable journey begins—a journey that intertwines tradition with innovation, and art with science. Maize, a staple crop that feeds millions around the globe, holds within its kernels the potential for sustenance, culture, and economic prosperity. Yet, the true magic of this multifaceted grain emerges not just in its cultivation, but in the intricate process of milling. This article delves into the world of maize milling, exploring the delicate balance between craftsmanship and technological advancement that transforms humble maize into diverse and essential products. From the rhythmic hum of modern milling equipment to the age-old techniques passed down through generations, we will uncover the complexities behind this vital process, celebrating both the artisans and the scientists who play pivotal roles in harvesting success in every kernel. Join us as we navigate through the fields of maize milling, where the past meets the present, and every grain tells a story of resilience and ingenuity.

Understanding the Maize Milling Process: From Field to Flour

The journey of maize from the field to flour is an intricate tapestry of art and science, where each step plays a critical role in attaining the final product. First, the harvesting of maize involves careful selection of the right time, usually when the kernels have reached optimal moisture levels for best quality. Once harvested, the drying process kicks in, reducing excess moisture to prevent spoilage. This is often accomplished with the aid of modern equipment, ensuring that the kernels remain intact and flavorful. After drying, the maize is subjected to cleaning to remove impurities, such as stones, dirt, and damaged kernels, which is essential for maintaining quality during milling.

The milling process itself is a complex sequence that transforms whole kernels into fine flour. Starting with grinding, the cleaner maize kernels are crushed into smaller particles. This stage can be performed using various methods

such as:

- Stone Grinding: Traditional method preserving flavor.

- Hammer Milling: Efficient and versatile for large batches.

- Roller Milling: Modern approach for producing uniform flour.

After grinding, the flour undergoes sifting to separate coarse particles from fine flour, ensuring a consistent texture that is perfect for baking and cooking. Often, this process is enhanced by air classification, which further refines flour quality by separating particles based on their weight. Together, these stages highlight the importance of precision and technology in every small batch of flour that makes its way into kitchens and products, demonstrating that the milling process is as much an art as it is a science.

Key Factors Influencing Quality: Selecting the Right Maize Varieties

When it comes to achieving exceptional quality in maize milling, the choice of maize variety is paramount. Not all maize cultivars are created equal; they offer diverse traits that significantly influence the milling process and the product quality. Understanding the key characteristics of different maize varieties helps farmers and millers alike to select those that align with their specific needs. Factors such as kernel hardness, starch composition, and nutritional content play crucial roles in determining the overall milling success and the end product’s suitability for various applications.

Moreover, environmental adaptability should not be overlooked when choosing the right maize variety. Selecting a maize type that thrives in local climatic and soil conditions can lead to enhanced yields and better quality. Some essential aspects to consider include:

- Resistance to pests and diseases: This protects crop health and ensures higher quality output.

- Maturational traits: Early or late maturing varieties can influence harvest timing and quality.

- Yield potential: High-yielding varieties contribute to efficiency in milling operations.

Ultimately, making an informed decision about maize varieties not only supports optimal milling processes but also fosters successful market positioning for milling businesses focused on quality.

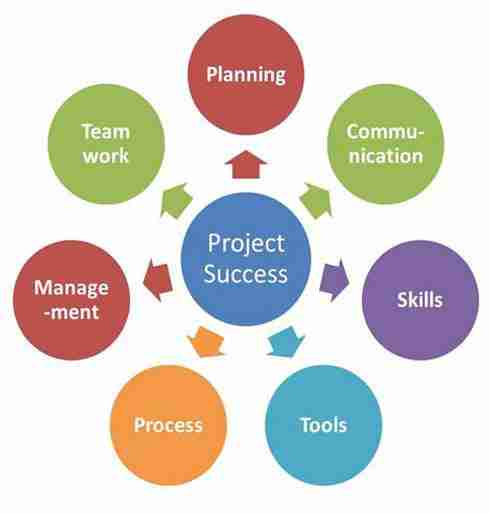

Optimizing Milling Techniques: Balancing Efficiency and Consistency

In the intricate dance of maize milling, striking the right balance between efficiency and consistency is crucial for maximizing output while maintaining quality. To achieve this harmony, milling operations can adopt various strategies that enhance productivity without compromising the end product. Implementing advanced milling technologies, such as high-efficiency milling machines or automated monitoring systems, allows operators to closely track performance and make real-time adjustments. Regular maintenance and calibration of milling equipment also play a vital role, ensuring smooth operations and minimizing downtime. Additionally, conducting routine assessments of raw maize quality can influence milling parameters, thus aiding in achieving a consistent final product.

The importance of staff training and knowledge transfer cannot be overstated in the quest for optimized milling processes. An informed workforce is better equipped to handle complexities arising during production. Emphasizing hands-on experience in the following areas can yield significant results:

- Machine operation and settings: Understanding how to properly set and adjust machinery.

- Quality control measures: Implementing checks to maintain desired product standards.

- Problem-solving techniques: Training staff to identify and resolve issues swiftly.

Furthermore, adopting a data-driven approach can provide invaluable insights into milling performance. Utilizing key performance indicators (KPIs) enables milling facilities to monitor efficiency and consistency over time. Below is an illustrative table of essential KPIs that can guide operational excellence:

| Key Performance Indicator | Description |

|---|---|

| Yield Rate | Percentage of maize converted into usable product. |

| Downtime | Total time equipment is not operational. |

| Consistency Index | Variability in product quality. |

Sustainability in Maize Milling: Innovations for a Greener Future

The maize milling industry is rapidly evolving, embracing new technologies and practices that prioritize environmental health. Manufacturers are increasingly focused on reducing their carbon footprint while enhancing efficiency. Innovations such as biomass energy systems are becoming more widespread, allowing mills to convert waste products from maize into energy for their operations. This circular approach not only minimizes waste but also significantly reduces reliance on fossil fuels. Furthermore, water conservation techniques, such as closed-loop cooling systems, are being implemented to recycle water used in the milling process, thereby reducing overall consumption significantly.

Another key aspect of sustainable milling lies in the adoption of smart technologies. These include IoT systems that monitor energy use and optimize production processes in real-time. Such advancements allow milling operations to run at peak efficiency with minimal energy expenditure. Additionally, the use of eco-friendly packaging materials is gaining traction, with many companies seeking alternatives to plastic to reduce environmental impact. The integration of these green innovations not only enhances operational sustainability but also responds to growing consumer demand for responsible sourcing and environmental stewardship in agricultural practices.

The Way Forward

the journey of maize milling is a fascinating interplay of tradition and innovation, art and science. As we have explored, the meticulous processes involved in transforming golden maize kernels into finely milled flour are not just about meeting consumer demands; they are about nurturing a deep-rooted agricultural legacy while embracing modern technology. The stories of farmers, millers, and consumers entwine to form a narrative rich in culture and sustainability, echoing the importance of this staple crop across the globe.

As we look to the future, the challenges and opportunities in the maize milling sector will continue to evolve, driven by advances in technology, environmental considerations, and the ever-changing palate of consumers. The key to harvesting success lies not only in the methods we adopt but also in our ability to adapt, innovate, and cherish the roots from which our food system flourishes.

As we close this chapter on maize milling, let us appreciate the alchemy of grains, the labor of hands, and the wisdom of generations that together create not just flour, but a foundation for meals shared and memories made. With every kernel milled, we embark on a journey that connects us to the land, to our communities, and to a future ripe with potential.