In an era where efficiency and sustainability are paramount, the agricultural landscape is witnessing a transformative shift with the rise of mini rice milling machines. Gone are the days when large-scale mills dominated the processing of one of the world’s staple foods. Today, small-scale farmers and entrepreneurs are discovering that innovation comes in compact sizes, offering practical solutions that enhance productivity while reducing costs. This article explores the burgeoning popularity of mini rice milling machines, examining their role in empowering local communities, promoting food security, and fostering a more sustainable agricultural ecosystem. As we delve into this revolution, we will uncover the factors driving their adoption and the potential impact they hold for rice producers around the globe.

The Evolution of Rice Milling Technology and Its Impact on Agriculture

The transformation of rice milling technology has been a critical driver behind the agricultural revolution, particularly in regions where rice serves as a staple food. Traditional milling methods were labor-intensive and time-consuming, often resulting in suboptimal grain quality and significant post-harvest losses. The introduction of modern equipment has vastly enhanced productivity, with mechanization allowing for faster processing and a reduction in labor demand. Mini rice milling machines, in particular, have emerged as game changers for small- to medium-sized farms, offering a compact and efficient way to process harvested grains right on the field. Their portability and ease of operation ensure that farmers can quickly transition from harvest to market, minimizing delays and maximizing fresh produce availability.

The impact of these innovations extends beyond mere efficiency. Mini rice milling machines not only improve production rates but also contribute to better grain quality. By reducing the amount of broken rice during milling, farmers can fetch higher prices in local markets. Furthermore, these machines are designed to use less energy, minimizing operational costs and making them accessible even to the smallest of farms. Key advantages include:

- Cost-Effectiveness: Lower initial investment and maintenance costs.

- Eco-Friendly: Reduced energy consumption compared to larger machinery.

- Quality Assurance: Enhanced milling precision yields higher-quality rice.

- Accessibility: Compact design facilitates use in diverse geographical locations.

As trends in agricultural practices continue to evolve, the integration of such technologies promises to sustain and enhance food security, empowering farmers with the tools needed to thrive in an increasingly competitive market.

Understanding the Benefits of Mini Rice Milling Machines for Small Holders

For small holders in the agricultural sector, mini rice milling machines serve as a transformative tool that revolutionizes the process of rice production. These compact yet powerful machines embody improved efficiency, allowing farmers to mill rice on-site rather than relying on distant commercial mills. This localized approach leads to several significant advantages, including:

- Cost-Effectiveness: Eliminating transport fees to larger milling facilities reduces overall operating costs.

- Freshness: By milling rice on their own, farmers can ensure that the product retains its nutritional value and flavor, as it is processed immediately after harvesting.

- Quality Control: Small holders have control over the milling process, which helps in maintaining the quality of the rice as per their market requirements.

Additionally, mini rice milling machines promote sustainability and self-reliance among small farmers. They provide an opportunity to create value-added products, fostering economic growth within local communities. By enabling farmers to capitalize on their production, these machines contribute to:

- Job Creation: The milling process can generate additional employment opportunities within the village.

- Increased Revenue: Farmers can sell high-quality milled rice directly to consumers or markets, leading to increased profits.

- Market Independence: By milling their own rice, small holders become less dependent on fluctuating market prices for processing services.

| Feature | Mini Rice Milling Machines |

|---|---|

| Size | Compact and portable |

| Power Source | Electric or diesel options |

| Milling Capacity | Up to 300 kg/hour |

| By-Products | Rice bran, husk |

Key Features to Look for in Mini Rice Milling Machines

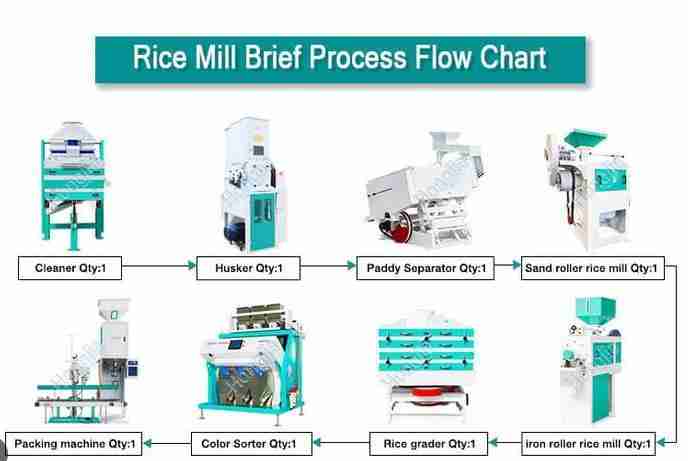

When selecting a mini rice milling machine, it’s essential to consider various features that can significantly affect performance and usability. Capacity is paramount; machines vary in their output, so choosing one that matches your processing needs is crucial. Additionally, look for a model with a multi-functional design, enabling it to perform various tasks such as husking, milling, and polishing, thus offering greater versatility in rice processing. Another crucial feature is energy efficiency, as machines that consume less power can reduce operational costs while being environmentally friendly.

Furthermore, consider the build quality and durability of the machine. Opting for models made from robust materials can ensure a longer lifespan and reliable operation under continuous use. Ease of maintenance should not be overlooked either; machines that are easy to clean and require minimal upkeep can save you time and effort. Lastly, the availability of spare parts and customer support is vital in case the machine requires repairs or upgrades. Ensuring you have access to support can greatly enhance your investment’s value.

Adopting Best Practices for Operation and Maintenance of Mini Rice Millers

Implementing efficient operation and maintenance protocols can significantly enhance the performance and lifespan of mini rice millers. Firstly, regular training sessions for operators can ensure proper handling and utilization of machines, minimizing the risk of errors that may lead to costly repairs. It’s essential to adhere to a maintenance schedule, which should include routine inspections and servicing of key components such as the hulling chamber, rubber rolls, and sieves. Moreover, operators should keep a detailed log of maintenance activities, which helps in predicting potential breakdowns and planning for timely replacements or repairs.

In addition to regular maintenance, optimizing the operational workflow can lead to remarkable gains in productivity. Utilizing standard procedures for loading, processing, and unloading can streamline operations. Employing automated systems for monitoring grain moisture levels and adjusting milling parameters accordingly can also greatly enhance milling efficiency. Furthermore, establishing a feedback loop with end-users allows operators to fine-tune processes based on customer preferences for grain quality. Below is a succinct overview of best practices:

| Best Practices | Description |

|---|---|

| Regular Training | Equip operators with necessary skills for efficiency and safety. |

| Maintenance Schedule | Routine checks to enhance durability and performance. |

| Standardized Procedures | Streamline operations for increased output. |

| Automated Monitoring | Adjust milling parameters based on grain conditions. |

| Feedback Mechanism | Enhance product quality based on consumer demands. |

In Conclusion

As we conclude our exploration into the transformative impact of mini rice milling machines, it’s clear that these compact powerhouses are reshaping the landscape of rice production. By combining efficiency with accessibility, they offer a tangible solution to the challenges faced by small-scale farmers and entrepreneurs alike. The rise of this technology not only highlights an important shift in agricultural practices but also signals a broader movement towards sustainability and self-sufficiency in food production. As we move forward, it will be fascinating to observe how innovations in the milling segment continue to evolve and inspire a new generation of agricultural advancements. Embracing these changes could very well pave the way for a future where food security is bolstered by efficiency and ingenuity, one grain at a time.