From Grain to Meal: The Art and Science of Maize Milling

In the heart of every culinary tradition, there lies a humble grain, a cornerstone of sustenance that has nourished civilizations for centuries. Maize, or corn, is more than just a staple; it is a cultural icon woven into the fabric of countless dishes worldwide. But have you ever paused to consider the journey this vibrant golden grain embarks upon from field to plate? The transformation of maize into meal is not merely a process of grinding; it is an intricate dance between art and science, where tradition meets innovation. Through a confluence of craftsmanship and technology, maize milling reveals a world rich in texture, flavor, and possibility. In this article, we delve into the fascinating realm of maize milling, exploring the techniques, machinery, and expertise that turn kernels into versatile meals, ready to elevate diverse culinary creations. Join us as we uncover the hidden complexities and the artistry behind every scoop of maize meal.

Understanding the Maize Milling Process: From Harvesting to Grinding

The journey of maize from field to flour is a meticulous blend of art and science, commencing with the careful harvesting of the crop. Farmers utilize various techniques, including hand picking and mechanized harvesters, to collect mature maize kernels at the optimal time, ensuring peak flavor and quality. The harvested maize then undergoes a series of essential steps to enhance its shelf life and prepare it for milling:

- Drying: To reduce moisture content, which is crucial for preventing spoilage.

- Sorting: Removal of damaged or inferior kernels to ensure consistency.

- Storage: Properly cleaned and dried maize is stored in controlled environments to maintain quality.

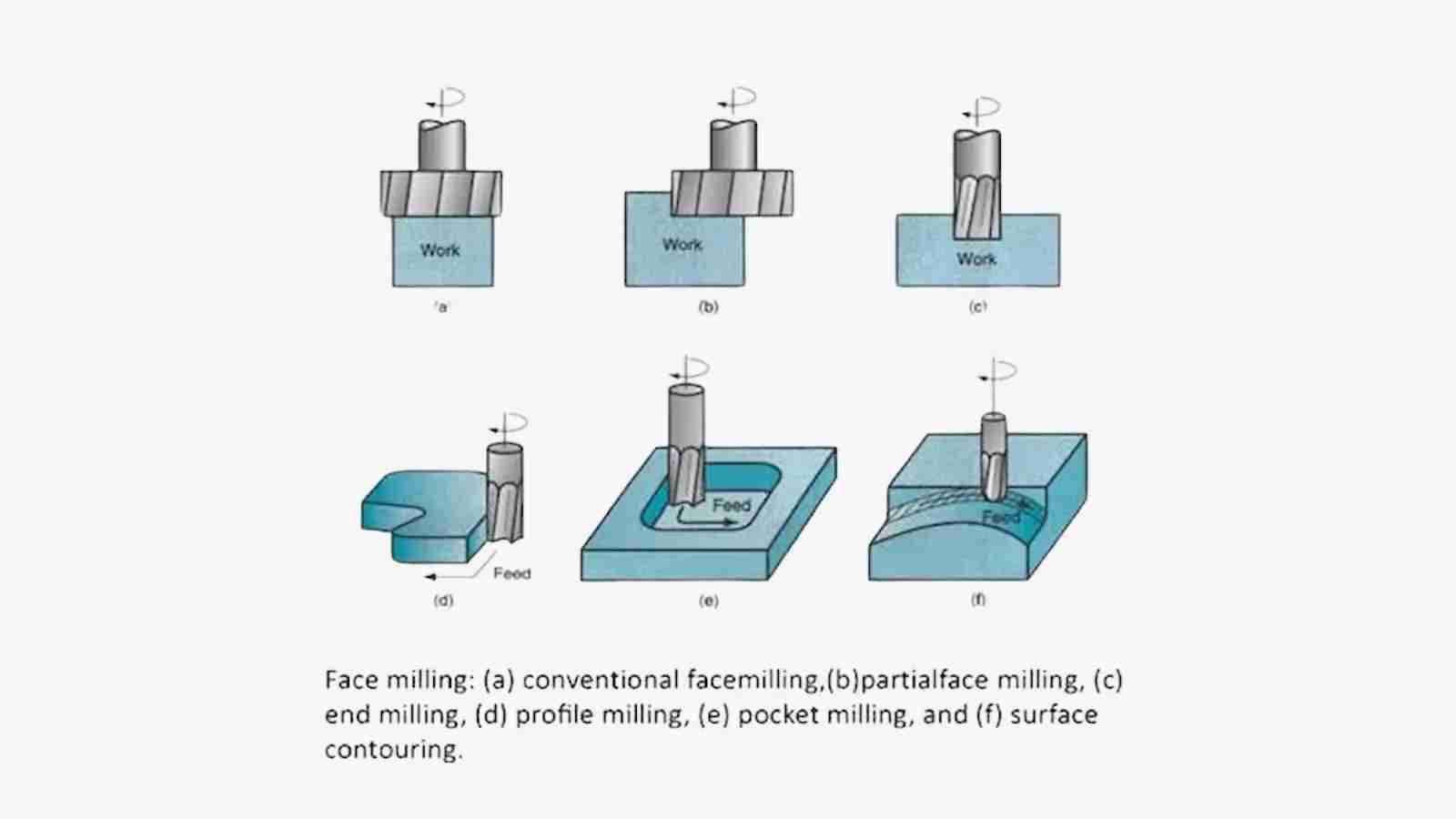

Once prepared, the milling process transforms the whole grain into a fine meal. This involves several stages that squeeze out maximum nutrients while minimizing waste. Key processes include grinding, which can be executed through various mill types such as hammer mills or stone mills, followed by sifting to separate different particle sizes. Some advantages of the milling stage are:

- Versatility: Enables production of different types of milling products like flour, grits, and meal.

- Consistency: Ensures uniformity in texture and quality.

- Flavor enhancement: The milling process can significantly enhance the taste and digestibility of the maize.

Exploring Different Milling Techniques and Their Impact on Quality

Milling techniques significantly influence the quality of maize meal, determining its texture, flavor, and nutritional value. Traditional stone milling is often celebrated for its ability to maintain the integrity of the grain’s natural oils, resulting in a richer taste and higher nutritional content. This method, while slow and labor-intensive, preserves the essential nutrients, giving the final product a coarser texture that many chefs and home cooks prefer. On the other hand, mechanical milling employs modern machinery to achieve finer grains at a quicker pace. While this technique increases efficiency and scalability, it often leads to higher levels of heat and friction that can degrade delicate nutrients, ultimately impacting overall quality and flavor.

The choice of milling technique not only alters the end product but also affects the culinary applications of the maize meal. For instance, coarse maize meal produced by stone milling is ideal for polenta and rustic breads, where texture plays a critical role. Conversely, finely milled products tend to perform better in baking and recipe requirements that demand uniformity. Below is a table showcasing some common milling techniques alongside their respective qualities and typical uses:

| Milling Technique | Quality Characteristics | Common Uses |

|---|---|---|

| Stone Milling | Nutty flavor, retains nutrients | Polenta, rustic breads |

| Mechanical Milling | Finer texture, quicker process | Pancakes, pastries |

Nutritional Insights: Enhancing the Value of Maize Meal for Consumers

Maize meal, rich in carbohydrates and essential nutrients, serves as a versatile staple that can significantly enhance dietary value when properly processed. The milling process can be optimized to retain vital components such as dietary fiber, vitamins, and minerals. For example, whole grain maize meal, which includes the bran and germ, offers higher nutritional density compared to refined alternatives. This means that consumers can benefit from a variety of essential nutrients, including:

- Vitamin B1 (Thiamine) - Supports energy metabolism.

- Folate - Important for DNA synthesis.

- Iron – Essential for oxygen transport in the blood.

- Magnesium – Aids in muscle function and energy production.

Moreover, the introduction of fortification technologies can further boost the nutritional profile of maize meal, making it even more beneficial for consumers. Essential nutrients, such as vitamin A, zinc, and iron, can be added in controlled amounts to achieve specific dietary goals. This is particularly important for combating malnutrition in vulnerable populations. A well-balanced maize meal product could not only serve as a food source but also play a crucial role in health interventions. Below is a simple comparison of traditional and fortified maize meals:

| Type of Maize Meal | Nutritional Benefits | Potential Drawbacks |

|---|---|---|

| Traditional Maize Meal | High in carbohydrates, some vitamins and minerals | Lower fiber and essential nutrients |

| Fortified Maize Meal | Enhanced with vitamins and minerals, higher fiber | Cost may be higher; possible taste differences |

Innovative Practices for Sustainable and Efficient Milling Operations

Embracing cutting-edge technology is crucial for enhancing milling operations while prioritizing sustainability. By integrating innovative practices, milling facilities can conserve resources and minimize waste. For instance, the use of precision farming techniques allows farmers to optimize grain quality, ensuring that only the best maize enters the milling process. Similarly, renewable energy sources, such as solar and wind power, are increasingly being utilized to reduce dependency on non-renewable resources while significantly cutting down on operational costs. Other advancements include automated grain sorting systems that help reduce spoilage and enhance overall efficiency by ensuring that only the highest quality maize is processed.

Furthermore, advancements in software and data analytics are revolutionizing maize milling operations by enabling real-time monitoring and optimization. By employing smart sensors and IoT devices, mill operators can track moisture levels, grain flow, and energy consumption, allowing for adjustments that improve efficiency and reduce waste. This is complemented by the implementation of closed-loop systems, which recycle excess heat generated during milling back into the process, thus conserving energy. Emphasizing a culture of continuous improvement, milling operations can engage in regular training programs for staff to highlight best practices in sustainability and efficiency, significantly enhancing both the environmental and economic aspects of the industry.

| Innovation | Benefit |

|---|---|

| Precision Farming | Improves grain quality |

| Renewable Energy | Reduces operational costs |

| Smart Sensors | Real-time efficiency optimization |

| Closed-Loop Systems | Energy conservation |

In Retrospect

As we conclude our exploration of the intricate journey from grain to meal in the world of maize milling, we find ourselves at the intersection of age-old traditions and cutting-edge technology. This process, steeped in history, is not merely a means of sustenance but an art form, where each kernel holds potential waiting to be unleashed.

From the expert hands of millers who have honed their craft over generations to the modern machinery that enhances efficiency and precision, the transformation of maize is a testament to human ingenuity. Each step, from selecting the finest cobs to the meticulous grinding that produces the perfect flour, reflects a nuanced understanding of both nature and science.

As we savor the final product—be it a warm tortilla, a comforting bowl of grits, or a fluffy corn muffin—we honor the journey it undertook. Let us cherish the rich flavors and textures that maize milling brings to our tables, and appreciate the countless stories woven into every grain. In this harmonious blend of art and science, we discover not just nourishment for the body, but also a profound connection to the past, present, and future of our food.