From Kernels to Flour: The Art of Maize Milling

In the heart of every kitchen, the ingredients tell stories—of origins, cultures, and traditions. Among these culinary narratives, maize holds a particularly vibrant place, its golden kernels a testament to both agricultural ingenuity and gastronomic versatility. From the fields where it sways in sun-drenched harmony to the intimate flourished dust of baking, the transformation of maize into flour is not merely a practical process; it is an art form. This article delves into the intricate journey of maize milling, exploring the techniques that turn humble kernels into a fine flour that enriches countless recipes. Join us as we unravel the layers of this fascinating process, from the labor of farmers nurturing the crop to the skilled hands that mill it, revealing the time-honored craft that turns simple grains into the foundation of countless culinary creations.

Understanding the Anatomy of Maize Kernels and Their Unique Properties

Maize kernels, the seeds of the maize plant, are intricate structures that hold a wealth of unique properties. Each kernel consists of three primary layers: the pericarp, which is the outer protective covering; the endosperm, which serves as the starchy food reserve; and the germ, which is the embryo that can grow into a new plant. These layers not only contribute to the kernel’s mechanical strength but also play vital roles in nutrition and milling characteristics:

- Pericarp: Rich in fiber, it helps maintain the integrity of the kernel and affects the milling process.

- Endosperm: The largest component, high in carbohydrates, crucial for flour texture and baking properties.

- Germ: Contains proteins, vitamins, and oils, contributing to flavor and nutritional value when milled.

The unique chemical composition of maize kernels influences their functionality in food applications. For instance, the balance of carbohydrates, proteins, and fats determines the quality of the flour produced. When analyzing maize attributes, several factors should be taken into account:

| Property | Impact on Milling |

|---|---|

| Moisture Content | Affects milling efficiency and flour quality. |

| Kernel Hardness | Influences the energy required for milling. |

| Protein Level | Impacts dough strength and baking performance. |

Understanding these aspects allows millers to optimize their processes and produce high-quality flour that meets various culinary needs, transforming the humble maize kernel into a staple ingredient in kitchens around the world.

The Milling Process Unveiled: Techniques and Equipment for Optimal Flour Production

The transformation from maize kernels to flour is a fascinating journey that involves a range of techniques and specialized equipment. Understanding this process is essential for anyone in the grain milling industry or even for home bakers looking to experiment with freshly milled flour. The journey begins with the careful selection of maize varieties, where the quality of the kernel plays a pivotal role in determining the flour’s texture and flavor. Once the kernels are gathered, they undergo several stages:

- Cleansing: Removing impurities such as dirt, stones, and other foreign materials.

- Conditioning: Adjusting the moisture content to prepare the kernels for effective milling.

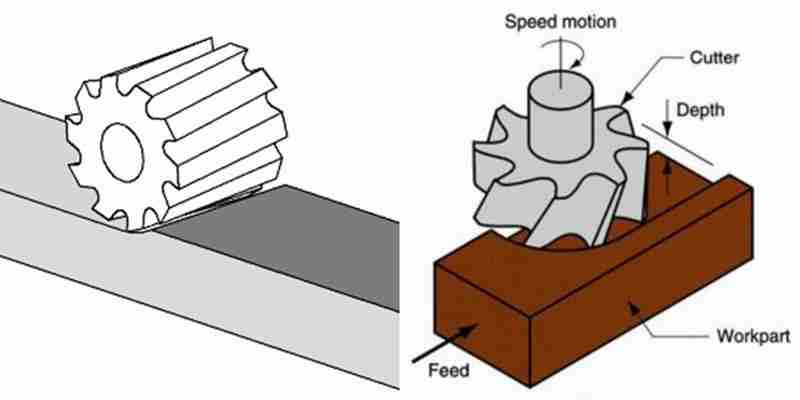

- Milling: The actual process of grinding the kernels into flour, which can be achieved through various methods such as stone milling or roller milling.

- Sifting: Separating the flour from the bran and germ to achieve the desired consistency.

Central to this process is the milling equipment itself, which can range from traditional stone mills that produce a coarser flour to modern roller mills that create a fine, consistent product. Each milling technique offers distinct advantages. For example, stone milling retains more of the kernel’s natural nutrients because of its gentle grinding method, whereas roller milling can process a higher volume of maize efficiently. Below is a concise comparison of these milling techniques:

| Technique | Advantages | Disadvantages |

|---|---|---|

| Stone Milling | Preserves flavor, high nutritional value | Lower yield |

| Roller Milling | High efficiency, fine texture | May lose nutrients |

Through these diverse methods and equipment, the milling process not only encapsulates the artistry behind flour production but also reflects a commitment to maintaining quality while meeting market demands.

Quality Control: Ensuring Consistency in Maize Flour Through Best Practices

Maintaining high standards in milling is crucial to achieving a consistent and quality product in maize flour. The journey from kernels to flour is marked by numerous checkpoints where quality control can make or break the final output. Best practices that ensure the integrity of maize flour include the following essential steps:

- Raw Material Inspection: Carefully assess the quality of maize kernels before milling, looking for any signs of mold, pests, or other deficiencies.

- Hygiene Practices: Implement strict sanitation procedures to prevent contamination during storage, milling, and packaging.

- Testing and Sampling: Regularly sample the flour at various stages of production to check for grain size, moisture content, and nutritional value.

- Process Monitoring: Employ state-of-the-art milling technologies that automatically adjust based on real-time data to maintain consistency in flour particle size.

Additionally, training personnel on quality assurance techniques ensures that everyone in the production line understands their role in maintaining standards. The following quality metrics should be monitored diligently:

| Metric | Standard Value | Monitoring Frequency |

|---|---|---|

| Moisture Content | 12-14% | Every batch |

| Granulation Size | 80% < 150 microns | Daily |

| Protein Content | 8-10% | Weekly |

| Aflatoxin Levels | < 20 ppb | Monthly |

By adhering to stringent quality control measures, producers not only enhance the reliability of their maize flour but also build consumer trust and satisfaction, culminating in a product that stands out in the marketplace.

Culinary Applications: Exploring the Versatility of Maize Flour in Different Dishes

Maize flour, with its finely ground kernels, opens the door to a myriad of culinary creations. This versatile ingredient shines in both savory and sweet dishes, offering unique textures and flavors that enrich every bite. From the comforting warmth of cornbread to the crispy delight of tortillas, maize flour enhances traditional recipes while inspiring innovative cuisine. Its gluten-free properties make it a staple for those with dietary restrictions, allowing for a wide range of adaptations without breaking the bank or compromising on flavor.

In the world of desserts, maize flour takes on an unexpected role, transforming classic treats into delightful experiences. Think of polenta cakes infused with fruit or a rich maize flour pudding that’s both creamy and satisfying. Exploring lesser-known dishes, such as arepas or empanadas, showcases the adaptability of this flour across cultures. Here’s a simple table illustrating some popular maize flour dishes along with their primary ingredients:

| Dish | Main Ingredients |

|---|---|

| Cornbread | Maize flour, milk, eggs, sugar |

| Tortillas | Maize flour, water, salt |

| Arepas | Maize flour, water, cheese |

| Polenta Cakes | Maize flour, butter, sugar, fruit |

In Retrospect

As we draw the curtain on our journey through the fascinating world of maize milling, it becomes clear that this age-old process is much more than a mere transformation of kernels into flour. It is a delicate interplay of tradition, technology, and artistry, reflecting the profound connection between people and their staple foods. Each step, from the careful selection of maize varieties to the rhythmic grinding and sifting, weaves a narrative that speaks to innovation and sustainability in food production.

Understanding the intricacies of maize milling not only enhances our appreciation for this versatile grain but also reminds us of the cultural significance embedded in our everyday foods. As we continue to explore and celebrate the diverse applications of maize flour—from tamales to cornbread—we honor a time-honored craft that has nourished generations and shaped culinary landscapes around the globe.

In embracing this journey from kernel to flour, we invite you to savor the flavors and stories that come together in each meal, making the ordinary extraordinary, one bite at a time. Thank you for joining us in this exploration of maize milling—a craft that will continue to evolve while keeping its roots firmly planted in the hearts of our communities.